With the pivotal role of trucking in transporting goods across regions, having access to comprehensive truck services along Highway 35 is paramount for varied businesses, including manufacturing, distribution, construction, and e-commerce. This guide provides an in-depth overview of truck maintenance and repair services, roadside assistance, and the significance of dedicated service centers for efficient truck operations. Each chapter carefully examines the intricacies of these services, ensuring that businesses can streamline their logistics and minimize operational disruptions through proactive truck care.

Under the Hood on Highway 35: The Essential Role of Truck Repair and Maintenance Along the Corridor

The stretch of Highway 35 and its parallels across states forms a lifeline for freight movements, weaving through industrial corridors, rural arteries, and urban hubs. For fleet operators and independent truck owners alike, maintenance and repair along this corridor are not afterthoughts but core parts of route planning. A breakdown on a remote bend or a missed maintenance interval can cascade into cascading costs, missed delivery windows, and safety risks that ripple through a supply chain. In this chapter, we explore how service centers near Highway 35—whether tucked into small towns or set up along major stretches—keep trucks moving, how operators evaluate their options, and why the most reliable choices blend technical capacity with practical access. The narrative unfolds not as a catalog of shops but as a map of the decisions that shape uptime, cost efficiency, and safety on long hauls and regional runs alike.

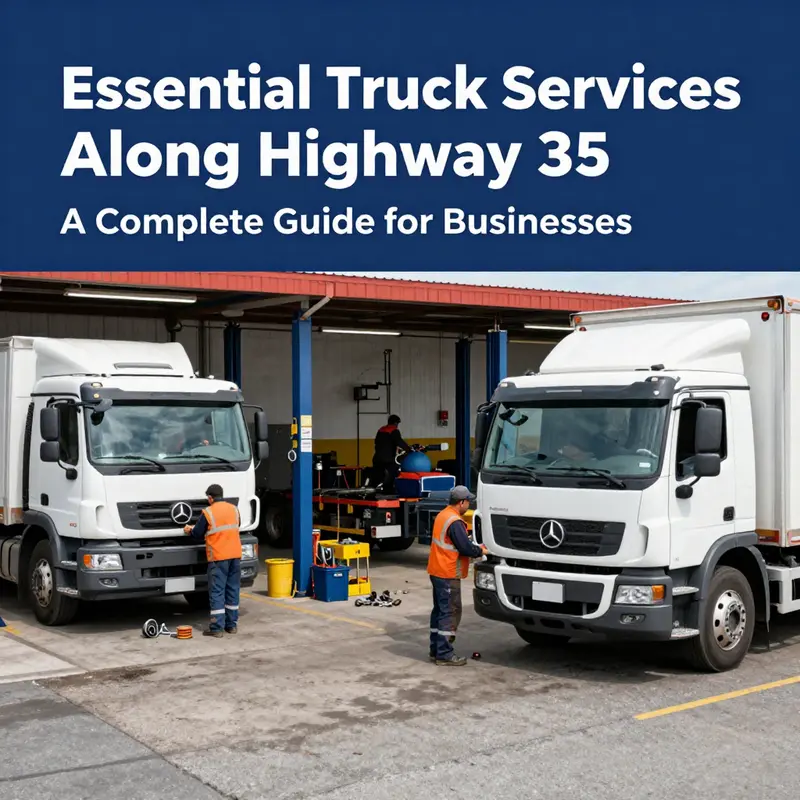

At the heart of dependable trucking is a precise alignment of capability and availability. Modern maintenance goes beyond routine oil changes and tire rotations. It encompasses a spectrum that includes preventive maintenance programs, diagnostic testing with up-to-date equipment, brake and suspension work, electrical and electronic system diagnostics, transmission and drivetrain repairs, and emergency roadside assistance. For fleets that log thousands of miles each week, the value of a service partner lies not only in the breadth of services offered but also in the speed and predictability of those services. A center that can perform a same-day inspection, diagnose a fault with advanced scanners, and complete a repair while a driver waits can transform a potential delay into a mere blip on the schedule. Conversely, a shop with limited capabilities or fragmented workflow can compound risk by forcing multiple appointments, or by relying on third parties to complete critical tasks.

Along a corridor like Highway 35, the geography itself informs service strategy. Towns with modest populations often anchor compact service facilities that emphasize reliability and quick turnaround for fleets that pass through. Larger towns and interchange hubs host full-service centers with heavy-duty equipment, advanced diagnostics, and a wider network of specialists. The mix matters because fleet operators frequently design maintenance windows around route planning, fueling stops, and delivery deadlines. A well-choreographed maintenance plan reduces idle time and keeps trailers aligned with load schedules. Operators who optimize maintenance consider not just what a shop can fix, but how fast and when it can be fixed. This includes the shop’s capacity to handle different vehicle classes—from light-duty to heavy-duty trucks—and its ability to perform comprehensive services during single or multi-day visits without sacrificing the next leg of the journey.

Among the practical considerations, proximity remains paramount. A service center within a reasonable driving distance can minimize the risk of a breakdown escalating into a costly detour. But proximity alone does not guarantee reliability. The strongest relationships are built on a blend of factors: trained technicians, modern diagnostic equipment, a track record of accurate estimates, transparent communication, and access to genuine parts or proven equivalents. For operators traveling along Highway 35, this means choosing facilities that maintain a robust parts inventory and reliable supplier networks to reduce backorder risk. It also means favoring shops that provide clear diagnostic takeaways and actionable maintenance plans, so dispatchers can decide whether a fix should be dispatched on the spot, scheduled for later, or routed to a nearby cross-town partner.

The value proposition for a service partner is often measured in the speed of diagnosis and the efficiency of the repair workflow. A modern truck service center operates like a manufacturing line designed for downtime reduction. The front-end process—check-in, diagnostic screening, and a comprehensive inspection—sets the tempo. A technician with access to a broad suite of diagnostic tools can rapidly pinpoint issues across systems, from engine management and fuel systems to brake circuits and air suspension. Then comes the back-end workflow: parts availability, technician scheduling, workshop layout, and the ability to allocate experienced specialists for complex repairs. The most effective shops maintain a lean, transparent chain of communication with fleet managers and drivers, so each stage—from initial assessment to final test drive—feels predictable rather than piecemeal.

Consider a representative service center along the Highway 35 corridor that emphasizes fleet maintenance across light, medium, and heavy vehicles. This kind of facility is set up to handle preventive maintenance programs that fleets often adopt as a core practice. Regular service visits under a maintenance schedule help detect wear before it becomes a fault, extending the service life of components and reducing the likelihood of urgent repairs on the road. In such a center, routine tasks—oil and filter changes, coolant checks, belt and hose inspections, brake pad monitoring, tire condition assessments, and lighting system checks—are integrated into a single, efficient workflow. Diagnostics for unexpected performance changes—such as rough running, unusual vibrations, or subtle steering deviations—are treated with equal seriousness, because the sooner a hidden issue is surfaced, the cheaper and quicker the resolution.

A concrete example from the corridor highlights the practical reality of these claims without anchoring to a single brand or storefront. In Knox, Indiana, a shop located along the Highway 35 corridor has built its reputation on fleet maintenance for commercial vehicles, with capacity to serve light, medium, and heavy-duty fleets. The facility emphasizes reliability, trained technicians, and a broad service offering that covers preventive maintenance, routine repairs, and more complex mechanical work. While the exact services shift with the needs of the day, the core capability remains consistent: a dependable partner that can diagnose common truck systems, perform essential repairs, and align with a fleet’s maintenance calendar. This kind of operation demonstrates how a regional center can become a reliable node on a freight network, enabling drivers to stay on schedule and operators to optimize asset utilization.

Beyond mechanical work, roadside and emergency support plays a vital role in keeping corridors like Highway 35 flowing. Roadside assistance fleets, tow services, and mobile repair units extend the reach of maintenance beyond the four walls of a shop. When a driver encounters a breakdown at night or in a remote stretch, the promise of swift, professional roadside service becomes as valuable as a long-term maintenance plan. The most effective providers in this space offer rapid dispatch, on-site diagnostics, and temporary repairs that clear the way for safer towing or for a full repair at a nearby facility. For operators running long-haul routes, these capabilities translate into dramatically reduced downtime, improved driver safety, and better route reliability. It is not merely the repair itself but the speed and professionalism of the response that matters.

Alongside the practicalities of service delivery, operators must weigh several strategic considerations when selecting a partner near Highway 35. Service range is a prime factor. A center that can cover a wide geographic footprint reduces the risk of stranded trucks far from home bases. This is often achieved through a mix of in-house capabilities and a network of trusted partners that share diagnostic data, inventory, and best practices. Operational hours matter as well. Round-the-clock availability can be the difference between completing a delivery on time and incurring penalties for late arrival. Likewise, the compatibility of a shop’s scheduling model with a fleet’s maintenance calendar is essential. Some fleets prefer coordinated, pre-scheduled maintenance windows to limit downtime, while others rely on on-demand diagnostic and repair work to address issues as they arise. Convenience extends to the parts supply chain. A service center that maintains a robust inventory or rapid access to commonly required components minimizes waiting times, a crucial factor when the clock is ticking on a delivery window.

Another subtle but powerful factor is the culture of communication. Drivers, fleet managers, and shop technicians must operate with clear, timely, and accurate information. When a diagnostic result is delivered with an understandable explanation and a transparent cost estimate, trust grows. That trust translates into better scheduling, fewer repeat visits, and a smoother path from inspection to road. In practice, this means service centers that invest in staff training, standardized diagnostic protocols, and customer-friendly reporting become preferred partners. It also means centers that respect the driver’s time—offering live updates on progress, anticipated completion times, and any follow-up maintenance recommendations—gain a reputational edge on corridors like Highway 35.

Within this ecosystem, a cross-cutting, sometimes overlooked factor is the depth of preventive maintenance culture within a fleet. Fleets that view maintenance as a strategic asset instead of a cost center tend to partner with service providers that align with that philosophy. This alignment often manifests in formal maintenance programs, scheduled inspections, and standardized service intervals that the shop understands and supports. When a center can deliver consistent, well-documented maintenance histories, it becomes easier for fleets to forecast parts usage, plan capacity, and optimize downtime. The literature on private fleets and maintenance trends underscores how preventive strategies reduce costly hydrocarbon leaks, late-stage wear, and reliability risk across the fleet. For readers seeking a broader lens on this topic, this discussion aligns with industry analyses that emphasize the move toward proactive maintenance and data-driven decisions, as captured in industry-focused explorations of private fleets and maintenance trends. Private Fleets Trends in Trucking Maintenance.

The Highway 35 corridor also invites a pragmatic view of how operators evaluate customer reviews, reliability, and hours of operation. It is common to consult multiple sources to triangulate a center’s competence: direct conversations with shop staff about capabilities; online reviews that speak to repair accuracy, timeliness, and billing fairness; and the observable readiness of a facility—its bay count, the melding of diagnostic equipment with a clean and organized workspace, and the cadence of maintenance cycles visible in the shop’s workflow. The most effective centers treat the customer experience as an extension of the repair work itself. They recognize that each interaction—from the first phone call to the final road test—shapes the driver’s confidence in returning for future service and the fleet’s overall uptime. This is why many operators insist on transparent pricing, precise estimates, and clear, written maintenance plans. The better centers not only fix what’s broken but also help drivers understand why the fix was necessary, how it fits into the vehicle’s longer-term health, and what proactive steps can prevent similar issues in the weeks and months ahead.

Of course, the corridor’s service landscape is not static. It evolves with traffic patterns, economic shifts, and technological advances in trucking. The growing emphasis on electrification, telematics, and data-driven maintenance promises to redefine which centers are most valuable to fleets along Highway 35. As electric and advanced-technology trucks become more common, shops that invest in high-voltage safety training, battery testing capabilities, and software-based diagnostics will become increasingly indispensable. Even for conventional diesel-powered fleets, the integration of telematics data with maintenance planning enables more precise scheduling and better asset utilization. The end result is a service ecosystem that not only repairs what’s broken but also predicts what will fail next and acts to prevent it.

In practical terms, the decision to choose one service center over another along Highway 35 boils down to a mix of factors: the breadth and depth of technical capabilities; the efficiency and reliability of the diagnostic and repair workflow; the shop’s geographic reach and hours; the transparency of pricing and communications; and the degree to which the provider supports preventive maintenance through structured programs. A center that can offer a comprehensive maintenance plan, responsive roadside assistance, and a well-organized, driver-friendly experience is not merely a place to fix a problem; it becomes a partner in keeping the fleet on the road. For operators who manage multiple trucks, the value of such a partnership compounds over time as uptime improves, maintenance costs stabilize, and resale value retains its edge due to well-documented service histories.

As a practical takeaway for drivers and fleet managers navigating Highway 35, the approach to choosing a maintenance partner starts with a clear assessment of needs. Identify the vehicle classes in the fleet, the typical route profiles, and the most critical maintenance intervals. Then map out potential centers along the corridor that offer the relevant services, have sufficient diagnostic capability, and demonstrate a willingness to commit to a maintenance program that aligns with the fleet’s schedule. It helps to ask for a sample maintenance plan and to request a transparent quote for common preventive tasks. When possible, seek centers that can demonstrate a track record of on-time, on-budget performance with minimal repeat visits. The goal is not simply to fix a problem but to build a durable, proactive maintenance habit that supports reliable delivery timelines, enhanced driver safety, and efficient asset utilization across the corridor.

For readers looking to explore industry context beyond the corridor, the broader conversation about trucking maintenance trends provides valuable framing. The evolution of fleet management, the shift toward preventive maintenance, and the integration of data analytics with maintenance planning are all relevant to how service centers position themselves to support modern trucking operations. This larger picture helps readers understand why a well-chosen service partner can be a strategic asset, contributing to safer roads, steadier schedules, and healthier bottom lines for carriers that rely on Highway 35 as a critical artery for moving goods.

External resource for broader context: https://maps.google.com/maps/place/Elite+Truck+and+Auto+LLC/@40.719235,-85.582876,15z/data=!3m1!1e3!4m5!3m4!1s0x882a2d1c1a1b1c1b:0x3f7f7a3b9a1a1a1a!2sElite+Truck+and+Auto+LLC,+680+N+US+Highway+35,+Knox,+IN+47604!3m2!1d40.719235!2d-85.582876

The Roadside Backbone Along I-35: How Nearby Truck Service Keeps Freight Moving

Along the long ribbon of Interstate 35, trucks carry the rhythm of commerce across landscapes that shift from hills to plains, from urban hubs to sleepy towns. The highway is more than a conduit; it is a living ecosystem where maintenance and repair are as essential as fuel and tires. When a driver rolls into the morning light, the thought that often keeps the wheels turning is not just the next loading dock but the quiet certainty that a capable service network sits within a practical margin of the corridor. It is the difference between a delay that compounds into a costly detour and a well-orchestrated response that returns the fleet to the road with minimal downtime. In this chapter, we explore how truck service near Highway 35 functions as a cohesive system—comprehensive, responsive, and tuned to the realities of freight movement along this crucial corridor—and how operators can map, evaluate, and rely on that system to sustain reliability, safety, and efficiency.

To begin, the roadside service network that supports I-35 is not a single entity but an interconnected matrix of solutions. There are specialized repair facilities that focus on heavy-duty needs—engine diagnostics, brake systems, transmission work, electrical troubleshooting, and alignment—paired with lighter, more nimble shops that handle routine maintenance and quick fixes. Between these are mobile repair units that can reach the roadside with diagnostic tools, fluid replenishment, and minor component replacements. The advantage of this layered ecosystem is clear: operators have options that fit a spectrum of distress, from a minor sensor fault that can be corrected in a few hours to a major breakdown requiring extended diagnostics and replacement parts. The goal, in every case, is to restore the vehicle to a safe, roadworthy condition as quickly as possible, without sacrificing the quality of the repair.

Reliability on the highway hinges on timely, predictable service. For fleets and owner-operators along the I-35 corridor, the value of a quick response is not merely convenience; it translates into fewer miles wasted, reduced detention time at customers’ facilities, and lower risk of cargo spoilage or damage. This is where a commitment to rapid mobilization becomes a defining feature of near-35 truck service. Mobile mechanics and roadside teams routinely optimize their routes with real-time knowledge of traffic, weather, and current shop workloads. They carry the diagnostic tools needed to identify issues on the spot and, when feasible, perform immediate repairs that keep the truck moving. When on-site work isn’t enough, these teams coordinate with nearby service centers so a vehicle can be towed or hauled to a facility that can complete more complex work without the clock ticking endlessly.

It is also important to recognize the role of preventive maintenance in reducing roadside incidents along a stretch like I-35. Operator fleets that adopt a proactive approach—scheduled inspections, lubrications, brake wear checks, coolant system evaluations, and tire condition assessments—tend to experience fewer emergencies. This is not about chasing a mythical perfect uptime but about building resilience into the transport chain. The near-35 service landscape supports this by offering convenient maintenance bays at strategic locations along the corridor, flexible appointment windows, and maintenance packages that align with common freight cycles. The outcome is a healthier balance between planned work at a shop and responsive on-the-road fixes when the unexpected occurs. Informed fleets use data to tailor maintenance cycles to the specifics of their operation, and the local service ecosystem responds by providing slots, parts availability, and skilled technicians who understand the regional driving conditions and load profiles.

When a breakdown occurs after hours or in a remote stretch, the difference between a lasting delay and a quick recovery often rests on a single decision: whom to call and how quickly they can respond. Roadside assistance in this context is not a luxury but a critical safety net. The best providers are not only capable of towing but also equipped to handle commercial trucks, with proper equipment to manage heavy payloads, secure loads, and protect the vehicle and cargo during transport. They understand the weight of a single breakdown in a fleet’s schedule and the downstream impact on customer commitments, schedules, and warranties. The breadth of services—emergency towing, winching, fuel delivery, lockout assistance, battery service, and urgent diagnostic fault finding—constitutes a complete package that dispatchers and drivers rely on when a pin on the map stops the system mid-journey. In practice, this means talk-time with a dispatcher who can assess the situation, a response vehicle that arrives with the right gear, and a team that can either fix the issue on-site or arrange a prompt, safe transfer to a repair facility.

Along the I-35 corridor, the geography itself shapes the service approach. Some segments pass through densely populated regions with multiple repair options and shorter towing distances; other stretches run through rural or semi-rural zones where the nearest response may be farther away. The distance to a capable service provider, the time of day, and the road conditions all influence how service is planned. A routine maintenance visit may be scheduled at a nearby shop during a planned rest period, while an emergency call is handled through a network that prioritizes speed and safety over cost. Operators often build a regional map of trusted partners—shops known for their diagnostic capability, trucks with the right lift capacity, and tow operators who can safely manage heavy loads. The outcome is a robust, prepared posture that reduces uncertainty for drivers and keeps the freight moving in a predictable pattern.

Within this framework, fleets and owner-operators weigh service range against the realities of routing, weather, and peak demand hours. A shop that sits at the crossroads of a handful of major corridors can become a pivotal anchor, offering not only repairs but also coordinating with other providers to ensure coverage at all times. The service network’s strength lies in its ability to deliver options that fit the situation: a quick diagnostic and minor adjustment on-site, a tow to a nearby repair facility with a proven track record, or a full-service repair center handling a complex engine issue after a scheduled appointment. Each option carries tradeoffs—on-site work may be faster but limited in scope; a tow to a center may take longer but guarantees a comprehensive repair with access to a broad inventory of parts. The savvy operator learns to interpret these tradeoffs and plan accordingly, ensuring that a contingency is in place for the next miles of travel.

The decision framework grows richer when the operator considers not just speed but the quality of the outcome. The most effective near-35 service nodes offer three things in tandem: clear communication, transparent pricing or at least a reliable estimate, and the expertise necessary to diagnose and address the issue without turning a simple fix into a protracted ordeal. Clear communication means a dispatcher who explains the likely causes of the fault, the steps the technician will take, and the expected timeline for on-site work or towing. Transparent pricing is especially important in a world where time is money and every hour spent waiting multiplies detention costs. Expertise translates into technicians who understand the specifics of heavy trucks, the weight distribution of trailers, and the safety standards required for heavy-duty repair, so repairs are reliable and durable, not quick-fix band-aids.

In this context, trust in a service network is earned through consistency, not merely through one-off incidents. Operator fleets benefit from building relationships with shops that demonstrate consistent diagnostic accuracy, reliable part availability, and predictable turnaround times. Reviews and feedback from fellow drivers and fleets become practical signals, telling what to expect when a job is booked or when a roadside call is placed in the middle of the night. The integration of maintenance planning with emergency response is what keeps the I-35 corridor resilient. A well-coordinated network allows a driver to anticipate service windows during rest periods, schedule preventive work in line with cargo commitments, and rely on emergency responders who know the terrain, typical traffic patterns, and the best routes for quick access to repair facilities or tow yards. It is a system built not just on tools and trucks but on trust, communication, and shared urgency.

When a breakdown happens near Highway 35, there are real-world examples of how the network operates in practice. Consider a tow and recovery provider located in a nearby city, capable of rapid roadside response and commercial truck repair, with service reach that extends to the highway corridor. While the exact name can vary by region, the principle remains the same: a provider with the right equipment, trained technicians, and a clear process can quickly evaluate the fault, determine whether on-site repair is feasible, and coordinate with a repair facility if needed. For drivers, the practical takeaway is simple: know whom to call, keep the contact information readily accessible, and understand the typical service window from dispatch to on-site arrival and the potential next steps. This is the practical embodiment of the corridor’s roadside backbone—an operational network that reduces risk, minimizes downtime, and helps keep freight moving with confidence.

For fleets interested in aligning with the strongest practices along the corridor, there is value in engaging with industry perspectives that address how fleets adapt to technological and regulatory shifts in trucking maintenance. The trend toward more data-driven maintenance planning, more proactive engagement with local service ecosystems, and a strategic emphasis on speed and reliability across all layers of the service network is well captured in contemporary discussions of trucking maintenance and fleet management. Private fleets, in particular, are increasingly embracing a proactive maintenance mindset, recognizing that the most reliable operation depends on anticipating needs rather than reacting to failures. This approach emphasizes the importance of a robust service map around Highway 35, with maintenance windows synchronized to freight schedules and a network of trusted providers who can deliver both preventive care and urgent support when the road throws a curveball. For readers seeking deeper context on these shifts, the conversation around private fleets trends in trucking maintenance offers useful background and strategic insight; see the discussion in the linked article to gain a sense of how operators are reorganizing their maintenance routines in response to cost pressures and safety expectations: Private Fleets Trends in Trucking Maintenance.

In practice, the decision to rely on roadside assistance or to drive to a nearby repair center is influenced by a simple calculation: what is the minimum exposure to risk and maximum chance of returning to service quickly? When the need is urgent, a nearby towing and recovery service with commercial capabilities becomes the first line of defense. Even when the vehicle can be repaired on-site, a quick professional assessment helps ensure that a fault is not masking a more serious issue that could surface soon. The proximity to a carefully curated network of shops along the corridor, the availability of after-hours service, and the ability to coordinate with dispatch to obtain a precise ETA and a detailed plan all contribute to a smoother recovery. In the end, the highway’s reliability rests on more than the vehicles themselves; it rests on the people and the process that stand ready at the edge of traffic to keep the wheels turning.

External resources can provide a practical frame of reference for the real-world dynamics of roadside support. For travelers and operators curious about how a specific service might appear in practice, a glimpse into the service provider landscape through mapping and profiles can be instructive. The above scenario, while not naming particular firms here, can be explored through a real-world example linked to a tow and recovery service located not far from the corridor. This resource offers a sense of distance, response capability, and geographic reach that complements the broader narrative of maintenance and roadside assistance along I-35. https://www.google.com/maps/place/High+Road+Towing+%26+Recovery/@40.185758,-82.498925,15z/data=!3m1!4b1!4m6!3m5!1s0x8840a3d5e1c8f9:0xc3b05c8f9a3d1a1!2sHigh+Road+Towing+%26+Recovery!3m2!1d40.185758!2d-82.498925!4m2!1d-82.498925!2d-82.498925?entry=ttu

The highway corridor thus merges practical, on-the-ground service with strategic maintenance planning. Operators who view their service network as an integrated ecosystem—one that blends preventive maintenance, emergency roadside responses, and selective long-haul repair capacity—are better positioned to navigate the uncertainties of long-haul trucking. They can move with less hesitation from road to shop, from diagnostic to repair, and from one service window to the next, all while maintaining a steady cadence of deliveries. And as the next chapter in this exploration unfolds, the conversation will deepen around how digital tools, data sharing, and cross-border regulatory realities influence the way near-35 service networks operate in practice, shaping the reliability and safety that underpins modern freight movement.

On the Blacktop Lifelines: How Service Centers Along Highway 35 Keep Trucks Moving

Along the curving lines of Highway 35, where coastlines meet inland corridors, a network quietly holds the freight economy together. For truck operators, reliability is not a luxury but a baseline operating condition. Every mile of road tests a truck’s Components, from engines and brakes to tires and electrical systems. The presence of a well-functioning service ecosystem along Highway 35 transforms what could be lengthy wait times into predictable maintenance windows, turning potential setbacks into opportunities to keep fleets moving. In this landscape, a single service center—like the Auto Care Center at a nearby Walmart—emerges not merely as a place for routine upkeep but as a vital node in a broader system that sustains efficiency, safety, and economic resilience for drivers who depend on timely deliveries and controlled costs. The corridor’s value is not only in the services offered but in the consistency of access, the tone of the staff, and the ability to address both minor irritations and more complex repairs with speed and competence.

Reliability in trucking starts with preventive maintenance, and preventive maintenance thrives where routine care is both accessible and affordable. Along Highway 35, a driver can count on a service hub that provides the basic maintenance menu: oil changes, tire rotations, battery checks, fluid top-offs, and comprehensive general maintenance. The idea is simple: catch small issues before they escalate into expensive breakdowns. When a truck stays in tune, fuel efficiency rises, wear patterns stay even, and the likelihood of roadside failures falls. This is not abstract theory but a practical advantage that directly ties into a carrier’s bottom line. Downtime is costly in a business built on time-sensitive deliveries, and any station designed to minimize that downtime earns a place in the routine of daily operations.

What makes these centers especially valuable along Highway 35 is their strategic position on routes that connect coastal communities with regional distribution hubs. The corridor acts as a backbone for freight moving in and out of Gulf ports, agricultural zones, and manufacturing nodes interspersed with rest areas, plazas, and infill facilities. An accessible service center within a reasonable drive from a loading dock or a highway exit translates into fewer detours, quicker fault isolation, and less time spent awaiting basic services. For long-haul operators, the economics of time are critical. A well-timed oil change or a tire rotation in the right location can prevent an emergency stop in a high-traffic stretch or a delay at a critical handoff. The effect ripples beyond a single vehicle; it scales across a fleet, improving uptime metrics, reducing the risk profile of an operation, and enabling more predictable schedules for customers who rely on dependable delivery windows.

The Auto Care Center in Rockport, situated on Highway 35 North, serves as a telling example of how these centers function as essential infrastructure. It is not merely a convenient stop; it is a reliable access point that glues the daily rhythm of trucking to a consistent maintenance cadence. The services offered are aligned with the practical needs of commercial fleets and owner-operators who traverse the route with varying loads and shifting schedules. Oil changes, tire services, battery checks, and fluid top-offs form the core package—an essential triage that keeps vehicles on the road. Yet the value extends beyond the checklist. The center’s capacity to handle routine maintenance quickly, coupled with a willingness to engage in more in-depth diagnostics when needed, helps drivers manage the unpredictable realities of road travel. The emphasis on general maintenance underscores a philosophy: trucks thrive when small, well-timed interventions are routine and unglamorous.

The convenience of extended hours emerges as a practical advantage for truck operators who routinely work outside traditional business days. The ability to pull off a quick service late in the afternoon or early in the evening is not merely a matter of comfort; it is a critical enabler of just-in-time logistics. When a driver can align a maintenance stop with a delivery schedule or a mandatory rest period, the overall plan remains intact. The economic logic behind extended hours is straightforward: fewer interruptions, lower queue times, and a smoother handoff between turns at the wheel and turns under the hood. In corridors like Highway 35, where freight moves with tight tolerances, this small adaptation in service delivery can translate into measurable improvements in fleet utilization and customer satisfaction.

Beyond the immediate mechanics of service, the presence of reliable roadside centers contributes to the resilience of the regional transportation network. Maintenance hubs absorb routine wear and tear, which in turn reduces the probability of unplanned breakdowns that would otherwise cascade into multi-vehicle disruptions. In freight economics, reliability is a form of reliability in pricing and planning. When a carrier can forecast maintenance events with a reasonable degree of certainty, it allocates spare parts, manpower, and downtime more efficiently. The cumulative effect is a region that can withstand the occasional shock—adverse weather, a temporary detour, or a surge in demand—without derailing the broader supply chain. This resilience is particularly important along Highway 35, given its role in connecting coastal economies to inland markets and supporting a steady flow of consumer goods, agricultural products, and industrial components.

The Rockport center’s placement, on a well-traveled artery, also contributes to the trust drivers feel when they roll into a facility. The expectation is not only that the staff will perform necessary maintenance competently but also that they will communicate clearly about what is happening and why. Trust reduces friction; it encourages drivers to choose a facility as part of their standard operating procedure rather than as an afterthought. In practice, trust translates into straightforward guidance on the next steps, honest assessments of when a service can be completed, and a transparent discussion of any follow-up actions that might be needed. It is a reminder that the most valuable interactions in trucking service are less about flashy, one-off repairs and more about consistent, dependable routines that keep vehicles within spec and fleets within budget.

From a fleet management perspective, the existence of service centers along Highway 35 enhances what policy analysts describe as “maintenance density”—the concentration of service options within a given travel corridor. This density matters because it reduces the risk associated with tire failures, brake issues, or cooling system faults that would otherwise force a vehicle off-route for a lengthy period. When maintenance density is high, fleets experience lower variability in uptime, making capacity planning more predictable. Operators can more confidently assign routes, anticipate maintenance windows, and reduce the buffer time they must reserve for contingencies. In a competitive market, those margins of predictability translate into real competitive differentiation. The capacity to keep a fleet moving with minimal disruption is a powerful asset in an industry where even small delays can ripple into late deliveries, missed slots, and penalties.

The broader literature on trucking maintenance and operational efficiency echoes what this corridor demonstrates in practice. Industry observers emphasize the role of preventive maintenance as a strategic lever, not just a maintenance expense. Fleets that prioritize routine care experience fewer roadside incidents, lower fuel consumption, and longer vehicle life. They also tend to enforce regulatory compliance more consistently, an important consideration for operators who must navigate hours-of-service rules, weight restrictions, and inspection regimes. A service center along Highway 35 thus becomes more than a place to top up fluids; it becomes a trusted partner in ongoing compliance, safe operation, and long-term asset management. When combined with the digital tools fleets increasingly deploy to monitor condition and schedule maintenance, these centers form a modern ecosystem that blends human expertise with data-driven scheduling.

An essential part of this ecosystem is the way service centers align with the realities of shift-based operations. For many truck drivers, the workday extends into the late evening or early morning. Having access to a center that can accommodate late arrivals without compromising quality is a practical necessity. The extended hours reflect an understanding that trucking success hinges on time as a resource—time not wasted waiting for service, time recovered through efficient checkups, and time saved by avoiding detours to distant facilities. On Highway 35, where traffic volatility can be a factor in wait times and route choices, predictable service timings help operators plan their routes around maintenance windows rather than the other way around. The result is a smoother operational cadence, with fewer surprises that could disrupt a carefully choreographed network of pickups and deliveries.

Looking ahead, the central question for operators along Highway 35 becomes how to integrate maintenance into their routine in a way that amplifies reliability without eroding efficiency. This means choosing centers with consistent turnaround times, visible qualifications, and a straightforward pricing structure. It also means seeking locations with the capacity to handle a spectrum of needs—from routine fluid checks to more involved diagnostics—without forcing a driver to become a hedge against delays. The Rockport center’s profile aligns with these criteria: a practical, no-frills maintenance option that can be counted on to deliver essential services quickly and competently. And because the corridor hosts a mix of local deliveries and longer routes, the ability to rely on such hubs is not a luxury but a contractual obligation between fleets and their customers. Driven by the daily realities of the road, maintenance strategy becomes a core component of route reliability, and Highway 35—through its service centers—plays a pivotal role in fulfilling that promise.

For fleets exploring how to stay ahead of maintenance challenges, a broader conversation is worth pursuing. Practices that emphasize routine inspection rhythms, standardized service checklists, and proactive parts stocking tend to yield the best outcomes in terms of uptime and cost control. Sharing insights across operators, learning from near misses, and aligning with centers that understand the particular demands of highway routing can create a culture of continuous improvement. The importance of local service options, like those along Highway 35, rests not only in the immediate services offered but also in the relationships formed between drivers, dispatchers, and technicians. These relationships facilitate quicker decision-making, better diagnostics, and a mutual commitment to getting the job done right the first time. In the end, the highway corridor becomes not just a route for moving goods but a living system that supports the people who move them and the communities that depend on timely trade.

Internal link for further reading: for fleets exploring how maintenance practices are evolving in private operations, see Private Fleets Trends in Trucking Maintenance.

External reference: a real-world example of a service center along the corridor can be found at the Walmart Auto Care Center in Rockport, which provides baseline maintenance services essential to keeping trucks in service. See https://www.walmart.com/store/4402401/auto-care-center for additional context on the standard maintenance offerings that support reliability along major routes like Highway 35.

Beyond the Next Toll: Navigating Truck Service Along Highway 35 for Maximum Uptime

Along the long ribbon of Highway 35, where freight lanes weave through busy metro corridors and rural pockets alike, the rhythm of a trucker’s day is defined as much by maintenance as by miles. When wheels roll smoothly, every load hits its mark, deliveries land on time, and a fleet keeps its promises to customers and partners. But on a corridor as dynamic as the 35 stretch, breakdowns are not a matter of if but when. The real challenge for operators is not simply finding a shop but discovering a service partner whose capabilities align with the demands of constant movement, ever-changing weather, and the unpredictable tempo of highway traffic. This chapter digs into what makes truck service near Highway 35 dependable, why certain attributes matter more than distance alone, and how operators can approach service decisions with a clear sense of value rather than just a price tag. It is a topic that sits at the intersection of safety, efficiency, and predictable scheduling, all essential for maintaining the cadence of nationwide freight.

Proximity matters, but it is not the sole determinant of quality. In the corridor along Highway 35, a service provider that sits just a stone’s throw from the interstate can dramatically reduce downtime when a vehicle falters at the worst possible moment. Proximity translates into faster response, easier logistics for mobile units, and reduced tow times when on-site repairs are not feasible. Yet proximity without capability is a hollow advantage. A robust service partner understands the realities of highway trucking, including the need for quick diagnostics, on-site repairs, and the ability to source parts with minimal disruption to a planned itinerary. For operators whose routes cross multiple state lines and whose loads carry perishable or time-sensitive goods, the tradeoffs between a near-by shop and a mobile repair team become critical. Mobile repair units, in particular, have moved from a convenience feature to a core component of fleet resilience. They carry specialized equipment and a focused set of skills that enable them to tackle frequent highway faults without the time sink of towing. The best scenarios blend both the local proximity of a well-equipped facility and the reach of a capable mobile team, creating a safety net that keeps shipments on their clocks even when the highway grows crowded or weather turns. This integrated approach is not a luxury; it is a practical strategy for reducing idling time and preserving uptime across the 35 corridor. In practice, fleets that commit to a network of near and mobile services often report fewer knots in their daily operations, smoother cycle times, and more reliable dispatch windows that match customer expectations with real performance.

A service provider’s range of capabilities is the heartbeat of reliability on Highway 35. The modern commercial truck presents a broad set of maintenance needs, from diesel engine quirks to brake system wear, from electrical diagnostics to heavy-duty transmissions. An anchor provider with a truly comprehensive mobile repair capability can address the majority of incidents on the shoulder or shoulder-raised lanes. The most valuable offerings include on-site diagnostics using up-to-date engine and electrical analyzers, the ability to perform advanced brake service, and the capacity to replace critical components like sensors, pumps, or actuators without requiring a tow. A well-rounded mobile unit will also bring the tools to handle common cooling system issues, fuel system troubleshooting, and emissions-related checks that are increasingly important in today’s regulatory environment. When a driver reports a fault light or a drop in performance, the sooner a technician can diagnose and correct the root cause, the sooner a truck returns to service. The value extends beyond the machine—it touches the schedule, the driver’s rest cycles, and the overall health of a fleet’s routing plan. Operators should look for providers who can demonstrate a broad scope of work and a track record of solving problems in the field rather than transferring the burden to a tow yard or a distant workshop. The most dependable partners also maintain a well-stocked inventory of common spare parts and accessories, enabling them to complete on-site repairs quickly and reduce the cascading delays that can ripple through a day’s lineup of trips.

Quality technicians and the right equipment are inseparable from dependable service along Highway 35. A technician who understands modern trucks—engine platforms, aftertreatment systems, transmissions, and high-utility electrical networks—can identify issues that are invisible to a less specialized technician. Certification matters because it signals that the person working on the truck has met standardized standards of knowledge and practice. Equally important is the equipment on the truck or in the mobile unit. Diagnostic laptops that interface with an array of truck brands, portable pressure and vacuum tools for braking systems, and a small, nimble set of spare parts all contribute to the speed and accuracy of repairs. For fleets that operate a mixed-vehicle environment—ranging from light-duty commercial trucks to heavy-duty tractors—the ability to service a diverse lineup on-site is a strategic advantage. It means the operator does not have to channel every issue into a single brand or a handful of models; instead, the service partner can map a repair path across different platforms, reducing cycle time and preserving more of the scheduled miles. In the highway 35 context, this capability translates into fewer detours and less backtracking as loads continue their journeys toward distribution centers, ports, and industrial parks. The result is a leaner operation where technicians act as engines of uptime rather than as obstacles to progress.

Availability and around-the-clock support are the lifeblood of highway trucking. The nature of freight means that breakdowns do not observe business hours, and a late-night stall can compromise a chain of deliveries that began days earlier. A truly responsive service partner offers 24/7 emergency coverage, rapid dispatch, and flexible scheduling that aligns with the cadence of freight flows. This is not simply about having a phone line open at night; it is about the ability to mobilize a team with the right skills who can arrive within a reasonable window, communicate clearly about what can be fixed on-site, and outline a transparent path if a tow becomes unavoidable. The best providers integrate dispatch systems that track in real time where the truck has stopped, where the technician is en route, and what parts are being used for the repair. For a fleet manager, this transparency matters as much as the actual repair. Real-time updates reduce the anxiety of waiting and support more accurate ETA readings for dispatch and customer commitments. Along Highway 35, where traffic can be unpredictable and weather can flip quickly, the reassurance of round-the-clock availability becomes a critical differentiator. It is a factor that fleets weigh when balancing cost against risk, recognizing that a small premium for 24/7 capacity can translate into continuous revenue rather than costly downtime.

Reputation and data-driven feedback complete the picture of what makes a service partner trustworthy on a highway corridor like 35. A thoughtful operator will examine online feedback, cross-check with multiple sources, and listen to the cadence of repairs—how often did the team succeed in keeping the truck on the road versus how often did a subsequent visit become necessary? The yardstick is not a single glowing review but a consistent pattern of performance across various scenarios: different truck models, diverse weather conditions, and the full spectrum of routine maintenance versus emergency repairs. In practice, an operator might rely on industry networks and word of mouth from fellow drivers and fleet managers to form a pragmatic view of which providers can be counted on when the clock is ticking. A balanced evaluation also includes operational metrics such as average response time, average time to repair, and the share of jobs completed on-site without towing. These metrics translate into tangible outcomes: shorter downtimes, steadier delivery windows, and a lower overall cost of ownership. In the decision process, it helps to incorporate a forward-looking perspective as well, considering how a provider adapts to evolving truck technologies and regulatory requirements. For instance, as fleets adopt new powertrains or emissions controls, a service partner’s capacity to stay current with training and equipment becomes equally important to its historical reliability. For readers familiar with industry dynamics, this aligns with broader themes such as the evolving economics of trucking maintenance and the transformation of service models in private and commercial fleets, a topic explored in depth in Private Fleets Trends in Trucking Maintenance. That piece helps frame the conversation around how maintenance strategies are adapting to new realities while Highway 35 continues to serve as a backbone for regional and national commerce.

Beyond the mechanics of repair lies a strategic mindset about planning and resilience. A thoughtful approach to truck service near Highway 35 begins with a proactive maintenance culture. Operators who schedule regular inspections, stay ahead of wear in critical systems, and maintain a spare parts plan reduce the likelihood of unexpected failures along the corridor. Proactive maintenance becomes a form of risk management that aligns maintenance windows with the travel realities of a busy route. When breakdowns do occur, the most effective response combines technical skill with logistics coordination. Dispatch teams can use digital work orders to assign the right technician, share the truck’s fault codes, and route replacements of parts to the repair site in a way that minimizes back-and-forth. The end result is a repair process that feels seamless to the driver, minimizes drayage time, and sustains the route’s schedule. In this sense, choosing a service partner near Highway 35 becomes less about proximity and more about a balanced ecosystem. It is about a network that can absorb shocks, support continuous operation, and maintain service-level commitments even when the road ahead is uncertain. When a carrier adopts this integrated approach, the 35 corridor rewards them with steadier cycles, improved asset utilization, and a stronger capacity to meet customer expectations without sacrificing safety.

The practical takeaway for operators and managers is to seek a service partner who offers more than a quick fix. Look for a provider who can demonstrate a broad capability set, a ready inventory of essential parts, and a proven track record of field repair excellence. Request diagnostics expertise, confirm the availability of 24/7 support, and inquire about on-site versus tow-based solutions. Ask for transparency around response times and the mechanisms used to keep customers informed throughout the repair journey. And remember that the most enduring partnerships often emerge from a shared commitment to continuous improvement. For those who want to explore broader industry context while considering maintenance strategies, the concept of private fleets trends in trucking maintenance provides a useful lens through which to assess how service patterns evolve in response to shifting technology, regulation, and market demand. See Private Fleets Trends in Trucking Maintenance for more on that topic. Alongside this, fleets can leverage digital tools that offer real-time tracking, GPS dispatching, and digital work orders to heighten transparency, accountability, and trust between drivers, fleet managers, and service partners. These tools do not replace skilled hands on the road; they empower them, ensuring each intervention is purposeful and timely.

In practice, a well-chosen service partner acts as an extension of a fleet’s own reliability standards. When a truck experiences a fault on Highway 35, the combination of proximity, capability, and dependable support turns a potential disruption into a managed event—one that preserves schedules, minimizes risk, and maintains the momentum of a long-haul operation. The landscape along this highway is not static; it features a spectrum of shops, mobile units, and digital ecosystems that together create a safety net for drivers and operators. To the driver, this translates into quiet confidence at night, knowing that if a warning light flickers or a mechanical niggle crops up, there exists a credible plan that minimizes downtime. To the fleet manager, it means a predictable cost of operation, a manageable risk profile, and an ability to promise customers a on-time delivery. This is the practical essence of maintenance strategy in motion along Highway 35: a continuous, collaborative effort to sustain the flow of goods that keeps supply chains intact and communities connected. For readers who want to dig deeper into the maintenance culture shaping trucking today, the internal reference to Private Fleets Trends in Trucking Maintenance offers a concise, focused lens on how fleets adapt to new realities while maintaining the backbone of reliability that Highway 35 represents across regions and industries. And for drivers seeking real-time practical guidance during trips, a widely used highway-exit resource can provide live information on stops, services, and potential delays, helping coordinate service needs with travel plans. External resource: https://apps.apple.com/us/app/iexit-trucks-the-truckers-highway-exit-guide/id1081954616

Final thoughts

In summary, the availability of reliable truck repair, maintenance, and assistance services along Highway 35 represents a valuable resource for various businesses reliant on transportation. By understanding the different service options and making informed choices about service providers, companies can optimize their trucking operations, enhance safety, and reduce downtime. The key considerations highlighted will empower businesses to establish long-lasting relationships with service providers who can meet their unique logistical needs, ultimately supporting their operational efficiency and success.