The presence of a ‘Service Air Bag’ warning light on your truck dashboard signifies a critical alert regarding the safety of the airbag system. This light is not merely an inconvenience but a potential harbinger of serious safety concerns should a fault exist within the airbag mechanism. For professionals in manufacturing, retail, construction, and other sectors relying on trucks for operations, it is vital to grasp the significance of these alerts. These chapters will delve into the underlying causes of this warning, emphasize the importance of addressing these alerts promptly, and outline effective methods for diagnosis and repair. In doing so, we aim to equip businesses with the necessary knowledge to ensure safe operations and compliance with safety standards.

When Your Truck Says “Service Air Bag”: What That Warning Really Means and What to Do Next

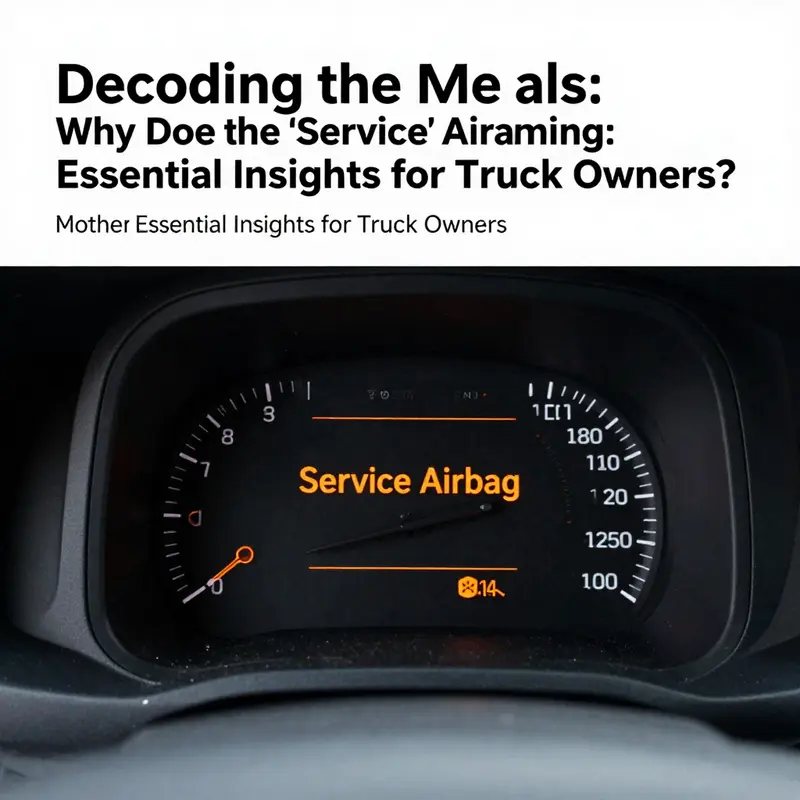

Seeing “Service Air Bag” on your truck’s dash is more than a nuisance. It is a direct message from the Supplemental Restraint System (SRS) telling you a critical safety system has found a problem. The airbag system is a network of sensors, wiring, and a control module. Each part must communicate perfectly for airbags to inflate correctly during a crash. When that communication breaks down, the system turns on the warning to prevent false confidence in occupant protection.

The message appears for several common reasons. Faulty crash sensors or accelerometers can fail to report an impact correctly. Wiring problems — frayed harnesses, corroded connectors, or loose plugs under seats — interfere with electrical signals. The airbag control unit, the brain of the system, can suffer software glitches or internal faults. Seat belt pretensioners and occupant detection modules are also tied into the SRS; their failures will trigger the warning. Even low or interrupted battery voltage can cause the system to lose its self-check and set a fault code. Any of these issues prevents the truck from reliably deciding when and how to deploy airbags.

Why you should treat this light as urgent is simple: airbags save lives only when they work. Research shows that a properly functioning airbag system deploys reliably in most crashes. But when the system is compromised, deployment rates and timing become unpredictable. In some studies, faulty systems saw deployment effectiveness drop dramatically. Worse, an uncontrolled or unintended deployment could occur in rare cases, causing injury or loss of control. That is why manufacturers and safety regulators require SRS warnings to be resolved quickly.

A driver-level understanding of the problem helps you respond correctly. First, realize the warning itself does not tell you which component is failing. It only means the system ran a self-test, found a fault, and stored one or more diagnostic trouble codes. Those codes are the technician’s roadmap. A trained mechanic or dealership has the specialized scan tools that read SRS codes. These tools reveal whether the trouble is a specific sensor, a shorted circuit, a memory fault in the control module, or a collision-related event that needs repair.

Some scenarios are straightforward. If you recently had work done near the steering column, seats, or door panels, a connector may not have been re-seated or an airbag clock spring may be misaligned. A battery replacement or a complete power loss can also throw codes; sometimes the light will clear after a proper reset, but that only applies when no underlying damage exists. Other scenarios are harder: water intrusion leading to corrosion in hidden connectors, prior crash repairs that used non-factory parts, or intermittent wiring faults that only appear when the vehicle flexes. These problems require careful inspection and sometimes disassembly to trace the issue.

Practical steps to follow when the warning appears are simple and safety-centered. Keep wearing your seat belt. The airbag system is an added layer of protection, not a substitute for the belt. Avoid DIY fixes that involve disconnecting or tampering with airbag modules. The pyrotechnic charges used for deployment retain the potential to deploy unexpectedly if mishandled. If you choose to drive before repair, drive conservatively and avoid high-speed traffic and risky maneuvers. But schedule a diagnostic scan as soon as possible. The correct diagnosis prevents wasted repairs and ensures the vehicle’s restraint strategy functions as designed.

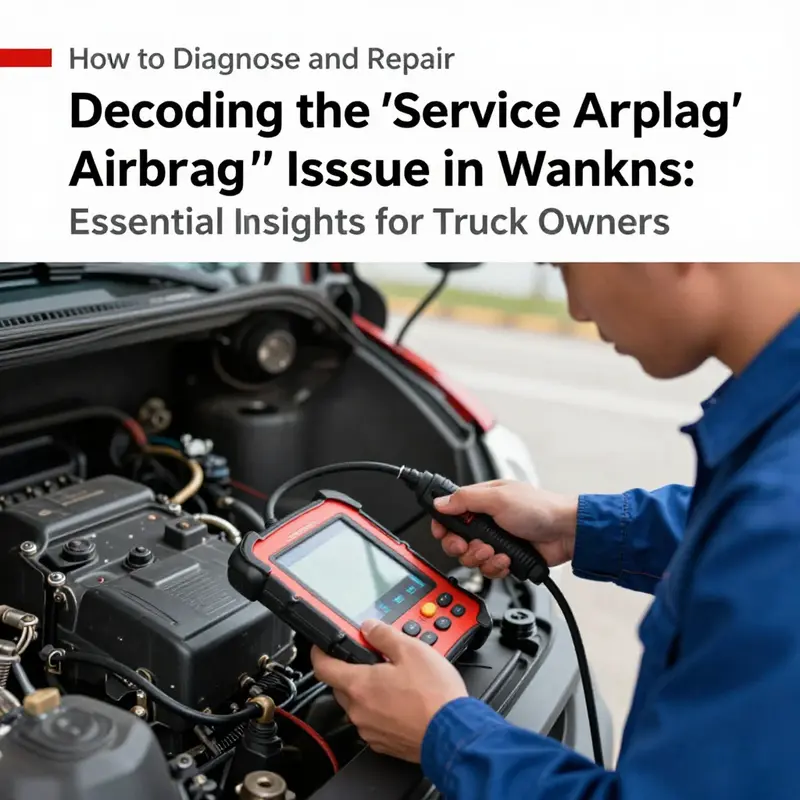

At a qualified shop, the technician will first read the SRS fault codes. Those codes often point directly to the failed component. A technician will inspect wiring and connectors, especially under seats where occupant detection and seat-belt pretensioner circuits run. The steering column will be examined for clock spring faults. Sensors near bumpers and frame rails are checked for damage. The control module itself will be tested for electrical faults and proper ground. Depending on the codes, technicians may perform resistance checks, wiggle tests to reproduce an intermittent fault, and visual inspections for corrosion or rodent damage. After repair, the SRS must be cleared and the system rechecked to ensure the fault does not return.

Knowing the likely culprits helps you understand the repair path. A damaged crash sensor or a bad clock spring is a typical, identifiable repair. Wiring harness repairs often require locating the damaged section and replacing or splicing with correct terminations. If the control module has failed, it may need replacement and programming tied to the vehicle’s VIN. Seat belt pretensioners, when triggered or faulty, require replacement as well. Any part containing the deployment charge must be handled by professionals. The costs vary by failure type and truck model, but the investment is for occupant safety.

There are also broader maintenance implications for fleet operators and owner-operators. A reliable maintenance program catches wiring wear and connector corrosion before an SRS fault appears. If your truck is part of a private fleet, adopting systematic inspection routines reduces unexpected downtime and improves safety compliance. For a deeper look at maintenance behavior among private fleets, review trends in routine checks and preventive strategies to reduce safety-related warnings and costly repairs. This perspective shows that small investments in preventive attention yield larger gains in safety and uptime.

Two other practical realities deserve attention. First, aftermarket or salvage parts used in crash repairs may not meet the original system’s standards. Non-factory modules or sensors can cause incompatibility faults. Second, environmental conditions matter. Trucks that operate in salty coastal regions or those exposed to heavy moisture often suffer connector corrosion faster. Regular under-seat and connector inspections in such environments reduce the chance of sudden SRS warnings.

If you’re trying to determine whether to drive the truck to a shop, weigh the risk. The airbag system’s failure does not mean the vehicle will brake or steer poorly. But it does mean your level of crash protection is reduced. Use seat belts rigorously and keep trips short until the system is repaired. If the fault light came on after a recent collision, or if you suspect water damage or electrical fire risk, avoid driving and have the vehicle towed to a repair facility. Repairs after collision events may involve structural inspection, occupant restraints, and proper replacement of all pyrotechnic devices.

Finally, documentation matters. When a technician repairs an SRS fault, request a copy of the diagnostic report and the fault codes found. This record helps when assessing recurring issues, verifying warranty coverage, or establishing the vehicle’s repair history. If your truck is used commercially, keep these records with maintenance logs for regulatory and insurance purposes.

A “Service Air Bag” warning should move you to action, not panic. Understand that the light is the car’s way of protecting you by flagging a system that cannot be trusted. Get the fault codes read, have trained technicians inspect wiring and sensors, and insist on quality parts and proper programming if modules must be replaced. Until then, rely on your seat belts and measured driving. For fleet managers, incorporate regular inspections into maintenance cycles to reduce SRS faults and improve safety metrics. For a focused look at maintenance approaches that help reduce these and similar safety issues, explore trends in trucking maintenance for private fleets.

For more information about airbag system safety and federal guidance, refer to the National Highway Traffic Safety Administration website: https://www.nhtsa.gov

When Your Truck Says “Service Air Bag”: What Triggers the Warning and What It Really Means

When your truck flashes “Service Air Bag”, it is more than a dashboard nuisance; it is a safety system telling you something has gone wrong. That message signals the vehicle’s supplemental restraint system has detected a fault. The system runs self-checks each time you start the engine. If anything is outside expected parameters, the airbag light or the text message appears. The causes vary widely, from simple wiring problems to failed control modules. Understanding the likely culprits helps you prioritize action, decide when to drive, and know what information to give your technician.

The airbag system is an integrated network. It includes the airbag control module that houses crash logic, numerous crash sensors distributed around the truck, wiring harnesses and connectors, inflators inside each airbag, and related restraint parts like seat belt pretensioners. The system depends on clear, reliable communications among these parts. When a sensor reports impossible data, or a circuit goes open or shorted, the control module logs a fault and turns on the warning. The fault could be intermittent or permanent, and it may prevent airbags from deploying in a crash.

A common root cause is a faulty airbag control module. The control module processes sensor inputs and decides whether to deploy airbags. If the module fails, or if its internal software corrupts, it may not accurately read sensors. Some modules use internal self-tests, and if those tests fail, the module sets a code. Control module failure can be sudden or the result of long-term exposure to moisture, electrical surges, or physical damage after a crash. Replacing a control module often requires programming or calibration, because it must communicate correctly with the truck’s other systems.

Damaged or disconnected wiring harnesses are another frequent reason for the service airbag message. Wiring travels under seats and through body panels. It endures daily vibration, contamination, and heat. Over time chafing can wear insulation away. Connectors can corrode from moisture. A single broken wire can sever communication between sensors and the module. The light may come on only when the vehicle moves, or only when a seat is occupied, if seat-occupancy sensors are involved. A careful visual inspection and a continuity test usually reveal wiring faults. Technicians often inspect the harness paths first, since wiring issues are common and relatively straightforward to fix.

Crash sensors themselves can fail or become misaligned. These sensors measure deceleration and direction during impacts. If a sensor is damaged, loose, or improperly mounted, it can send inaccurate data. The control module expects sensor signals within a specific range. When it detects values outside that range, it sets a fault. Sometimes a sensor will work intermittently—passing self-tests under certain conditions and failing under others. Technicians rely on diagnostic fault codes to identify which sensor triggered the warning. Replacing or repositioning the sensor restores correct readings.

Airbag inflators and deployment mechanisms can also trigger warnings. Inflators contain the gas-generating material that rapidly inflates an airbag in a crash. If an inflator has a manufacturing defect, or was damaged in a previous crash and not properly replaced, the system will detect anomalies. After a deployment, airbags and inflators always require replacement. Failure to install approved replacement parts or poor installation can cause the system to detect a problem. Inflator issues can be serious because they directly affect the ability of the airbag to function during an impact.

Loose or improperly installed airbag modules are often overlooked. Airbag modules must be mounted securely. Vibration or DIY repairs can leave bolts loose or connectors only partially seated. A module that is physically unstable can fail its self-test and trigger the warning. This is why any repair involving seat removal, dashboard work, or steering wheel service must be done carefully. Reinstalling modules and connectors to manufacturer torque and alignment specifications usually clears the fault.

Seat belt pretensioners and other restraint components share circuits with airbags on many trucks. A pretensioner short or open circuit may appear as an airbag system fault. Seat sensors, especially in passenger seats, also influence the system. If the seat occupancy sensor misreports weight, the system might disable the passenger airbag or flag an error. People who frequently change seat covers, or who carry heavy items on the seat, can inadvertently trigger a warning.

Electrical system health matters too. Low battery voltage or charging system issues can cause strange airbag behavior. The airbag system relies on stable voltage during its self-checks. If the battery is weak or the alternator is failing, the airbag module may detect insufficient voltage and flag a problem. This is why some fault codes appear after extended periods of battery drain or following a jump start that caused a voltage spike. Always check basic electrical health before assuming other components have failed.

Not all faults mean immediate catastrophe, but none should be ignored. A lit “Service Air Bag” light means the system could fail to deploy, or it could deploy unexpectedly. Both outcomes are dangerous. If the light appears after a recent crash, suspect that airbags, sensors, or the control module need replacement or reprogramming. If it appears after battery work or a recent service that involved disconnecting parts under a seat, suspect a loose connector. If the light comes on gradually or randomly, wiring or sensor faults are likely.

Technicians diagnose airbag warnings using a methodical approach. The first step is to read fault codes from the airbag control module with a diagnostic tool. The codes indicate which circuit or sensor reported an error. Visual inspection follows. Technicians look for damaged wires, corroded connectors, loose modules, and signs of previous deployments. They perform continuity and resistance checks on suspect circuits. In many cases, a single connector reseated or a wiring repair clears the code. In other cases, module replacement and programming are necessary.

You can take meaningful steps before visiting a shop. Start by ensuring the battery is fully charged. Check under seats for disconnected plugs. Avoid attempting repairs that require disabling the airbag system unless you are trained and follow safety protocols. Never use a generic scanner that cannot communicate with the vehicle’s airbag module. Those scanners can miss manufacturer-specific codes. Also, be aware that some trucks require a technician to use special tools to reset or reprogram the airbag control module.

If you manage a fleet, consistent maintenance practices reduce airbag faults. Regular inspections of seat harnesses and under-seat wiring prevent chafing and connector corrosion. Training technicians to follow manufacturer procedures when replacing seats, modules, or inflators prevents installation-related warnings. Insights on maintenance trends in private fleets can help fleets prioritize preventative work and reduce downtime; see this piece on trends in trucking maintenance for fleet-focused strategies. Small investments in preventive checks often avoid costly module replacements and reduce safety risk.

When a fault requires parts replacement, use only approved components. Airbag inflators, control modules, and sensors must meet manufacturer specifications. Improper or low-quality replacements can reintroduce faults or, worse, compromise deployment performance. After a repair, the system must be tested and, if required, the module reprogrammed. Some vehicles require alignment procedures or crash-data reinitialization. Skipping these steps may clear the light temporarily while leaving the system unable to respond properly in a collision.

Finally, treat “Service Air Bag” warnings as urgent. Driving with a disabled or compromised airbag system increases risk for everyone inside the cab. If the warning appears while you are on the road, drive with increased caution. Avoid high-speed travel until you can confirm the system is healthy. Seek professional diagnosis promptly. A qualified technician will use diagnostic codes, inspections, and proper replacement parts to restore your truck’s protection.

For a deeper technical overview of how airbag systems perform and how manufacturers describe their behavior, review the technical airbag overview provided by the manufacturer referenced in this chapter. It explains performance expectations and system components in more detail: https://www.volvotrucks.com/technical-support/airbag-systems/.

When the Airbag Light Warns: Why Quick Action on a ‘Service Airbag’ Alert Protects You and Your Crew

A truck dashboard can flash many messages, but few carry the same weight as a blinking or steady “Service Air Bag” warning. In plain terms, that light is telling you the vehicle’s Supplemental Restraint System (SRS) has detected a fault serious enough to potentially disable one or more airbags when you need them most. It is not a cosmetic nuisance or a reminder to change a fuse; it is a safety-critical alert that should trigger immediate attention. The airbag system is a coordinated web of sensors, control modules, wiring, and the airbags themselves, all designed to respond within milliseconds after a collision. When the warning illuminates, it signals that something in that web has failed or drifted out of spec. And because the stakes involve your life and the lives of others in the cabin, the responsible response is not to ignore it, reset it on a whim, or assume the light will go away on its own. The path from a warning to safer driving starts with understanding what the system is, what can go wrong, and how to navigate the diagnostic and repair process with a qualified technician who can verify the fault with proper tools and procedures.

The SRS does not operate in isolation. It depends on a network of sensors placed in strategic locations—often in the front and side areas of the vehicle—and a central control module that decides when to deploy the airbags in a crash. This coordination is sensitive to electrical health, mechanical connections, and the integrity of the airbags themselves. Among the most common culprits behind a Service Air Bag warning are a loose or corroded wiring harness under seats or in the cabin, which can degrade signal transmission over time due to vibration, moisture, or even rodent damage. In some cases, a seat track or occupant classification sensor—designed to determine weight thresholds and seating position—can become miscalibrated or fail, triggering a fault code. The result is a light that may stay on or flash intermittently, reflecting a fault that could compromise front-seat or side-curtain airbag deployment when a crash occurs.

Vehicle-specific quirks also shape how this warning manifests. For example, some engineering teams have noted that certain German-engineered systems can register misaligned sensor thresholds, producing false alerts that still demand attention. In other markets, the spoke-of-seasons nature of wiring under seats has earned a reputation for being a frequent source of trouble, where vibration, humidity, and even pests create an unseen damage pattern. The reality is that these failures are not abstract. They directly affect whether an airbag will deploy correctly, whether a seat belt pretensioner will function as intended, or whether the system will defer to a non-deployment that can leave occupants exposed during a serious impact. The sum of these potential faults is why experts insist the warning light should be treated as a priority rather than a nuisance.

To citizens and fleets alike, the message is clear: a Service Air Bag alert signals a fault that may compromise occupant protection. This is especially crucial in trucks that carry drivers, passengers, or heavy cargo across long distances and in demanding driving conditions. Even if the truck appears to run normally in daily driving, a fault in the airbag system can disable deployment at the precise moment it is most needed. The risk is not merely theoretical; airbags rely on precise timing and electrical reliability. A failure in any part of the system can translate into a moment when a collision demands maximum protection but the system is unable to respond. This is why the guidance from safety and automotive specialists is consistent: do not ignore the warning, do not attempt a DIY reset, and do not postpone professional diagnosis.

Diagnosing a Service Air Bag condition begins with recognizing that fault codes live in the vehicle’s onboard computer. An OBD interface is not merely for emissions or engine faults; it is also the entry point to the airbag system’s fault logging. When a technician connects a compatible diagnostic tool, the system can reveal a code that points toward a sensor, a wiring harness, the airbag module, or a pretensioner. Those fault codes guide the technician to the likely location and cause of the problem, but the path from code to repair remains thorough. A code can tell you that a sensor is reporting out of range, that there is an intermittent interruption in a circuit, or that a module is not communicating properly with other SRS components. It is essential to understand that reading a code is not the end of the journey—it’s the starting point for a structured diagnostic process that verifies the problem and rules out false positives. In many cases, the underlying issue is a hardware fault rather than a software glitch; in other cases, a battery or charging system problem can cause low voltage that renders the airbag system unresponsive or temporarily disables it to preserve electronics integrity.

The technician’s approach to a Service Air Bag condition is both methodical and safety-focused. It begins with a careful visual inspection of visible harnesses and connectors, especially those under the seats. The under-seat region is a frequent hotspot for problems because people move and slide on seats, plug or unplug accessories, and the environment beneath can accumulate moisture or debris. During inspection, technicians look for cracked insulation, corroded terminals, loose connectors, and any signs of intrusion or bite marks from rodents. They also verify that seat frames and tracks are aligned and free of damage that could affect occupant sensing or the integrity of the harness routing. In addition to visual checks, a series of diagnostic steps is performed using the tool connected to the vehicle’s data network. The tool pulls fault codes, logs live data from sensors, and sometimes runs simulated tests to determine if a sensor or module is failing or simply reporting a stale error.

One crucial aspect that often emerges in professional assessment is the need to verify power supply stability. A weak battery or irregular voltage can trigger protective measures in the airbag system, temporarily disabling deployment to avoid damage to the electronic components. For fleets that operate in variable climates, thermal extremes can also subtly affect sensor performance and wiring insulation over time. The diagnostic journey therefore includes ensuring the battery and charging system are healthy, the voltage rails are within specification, and that there are no parasitic draws or abnormal loads that could compromise system readiness. These steps are not merely about clearing a code; they are about confirming the reliability of the SRS in every possible condition that a truck might encounter on the road.

Choosing to repair the airbag system is not a case of replacing a single part or clearing a light. It requires a careful decision about what needs replacement and how to test the system after reassembly. Replacing a sensor, for example, is not a one-to-one fix if the wiring or connectors around the sensor have sustained damage. A technician will typically re-test after any replacement, re-scanning to confirm that the fault code is cleared and that the system registers proper deployment readiness. This means not only a code-free reading but also a confirmation that the system recognizes proper sensor input, aligns with the correct seating configuration, and passes a functional test of the airbag module and pretensioners. In many cases, the repair spans beyond a single component to address multiple points of failure that have emerged as the system aged and endured environmental stressors.

For fleets focused on reliability and uptime, the Service Air Bag warning is a reminder that safety cannot be segmented from maintenance. The cautionary point is not to think of airbags as a passive safety feature that operates only in a crash. They are an active, adaptive network that requires ongoing integrity checks, calibration, and, when necessary, component replacement. This aligns with broader maintenance thinking that emphasizes proactive, data-informed care rather than reactive fixes. In the trucking world, where downtime translates into cost and schedule disruption, it becomes imperative to seek diagnosis promptly and to plan repairs in a way that minimizes risk and keeps vehicles in service once the system is confirmed to be safe. The relationship between warning lights and real safety is not speculative; it is grounded in the engineering design of modern restraint systems, which prioritize deployment timing and reliable function to reduce injury severity in crashes.

The practical steps, therefore, begin with immediate recognition of the warning and a move toward professional assessment. Do not rely on a quick reset or a dashboard clearing technique, because that approach hides a fault that could reappear or fail under stress. Instead, schedule service with a certified shop or dealership that has access to the vehicle’s fault codes, proper diagnostic tooling, and technicians trained in SRS safety protocols. The diagnostic session often starts with a controlled environment and a careful plan to isolate the fault without triggering accidental deployments. The technician must observe strict safety precautions when handling airbag modules and pretensioners, which are designed to deploy under specific conditions. It is a specialized process that requires factory-approved procedures, correct replacement parts, and, crucially, a zero-tolerance approach to risk during the repair work. Fleets that prioritize this kind of professional handling typically experience lower long-term costs and better occupant protection, which underscores the fundamental point: addressing the Service Air Bag alert quickly is not an extra expense; it is a core investment in safety and reliability that can pay dividends in real-world outcomes.

To those overseeing fleets or long-haul operations, there is a broader lesson embedded in this warning. Regular maintenance that tracks the health of safety-related systems, including the airbag network, can catch issues before they become critical. Industry conversations across fleets highlight the value of proactive checks, especially in vehicles subjected to high mileage or harsh operating environments. This is where maintenance trends in trucking maintenance come into play. By embracing a proactive mindset—conducting routine inspections of seat wiring, connectors under seats, and the general health of the SRS wiring harnesses—fleets can reduce the likelihood of a mysterious light turning into a costly downtime episode. The point is not to chase every microscopic fault but to build a disciplined diagnostic habit that keeps safety systems ready for operation and keeps trucks on the road where they belong. For readers who want to explore this broader maintenance context, a recent analysis of private fleets trends in trucking maintenance provides deeper insights into how fleets are investing in preventive care and safety-system upkeep. private fleets trends in trucking maintenance.

The journey from a Service Air Bag warning to a repaired, validated, and ready-to-drive state is not simply a matter of technical know-how; it is a process of prioritizing safety, acknowledging that passenger protection hinges on reliable electronics and mechanical connections, and accepting that the only responsible action is to engage qualified professionals who can perform a comprehensive assessment. In this frame, the warning light becomes less a nuisance and more a call to action—an actionable signal that, if heeded, sustains the protective purpose of airbags and preserves occupant safety across countless miles of service. It is a reminder that the most dependable truck is not only the one that travels the farthest but the one that travels those miles with readiness to protect lives when the moment comes. And while the initial response is to seek expert help, the ultimate outcome—a system that deploys as designed in a crash—rests on the thorough, careful, and timely attention given to the Service Air Bag alert.

For readers seeking further authoritative guidance on airbags and vehicle safety, consult trusted safety resources that summarize deployment principles and diagnostic best practices. This external perspective reinforces the core message: a Service Air Bag warning is a safety-critical alert that warrants prompt, professional evaluation rather than a casual reset or postponement. External resource: https://www.nhtsa.gov/road-safety/vehicle-safety-airbags

From Light to Reliability: Diagnosing and Repairing Service Airbag Warnings in Modern Trucks

When a truck’s dashboard springs to life with a red warning—often the familiar AIRBAG icon or a silhouette of a seated occupant—the message is more than a nuisance. It is a safety-critical alert signaling that the airbag system, or the surrounding suspension and restraint components that interact with it, has detected a fault or an imminent risk. In modern trucks, where electronic control systems govern not only airbags but also sophisticated air suspension and height adjustment features, that light represents a fault in the nervous system of the vehicle. It is a warning that cannot be dismissed with a quick restart or a casual reset, because the consequences of an inoperative airbag or an unreliable suspension during a crash can be severe. The logic behind the warning is straightforward, yet its diagnosis often requires a careful, methodical approach that blends observation, diagnostics, and verification. The journey from noticing the light to ensuring true reliability is not a matter of guessing. It is a process grounded in the fundamentals of how airbag sensors, control modules, and the electrical networks of the vehicle interact, and it is framed by the practical realities of how trucks operate in the field—where moisture, vibration, and leaks can reach the heart of a system and influence performance in unexpected ways.

The first consideration is to understand what the system comprises. The airbag network typically includes impact sensors placed in strategic locations, a central controller or airbag module, wiring harnesses and connectors, the airbags themselves, and in many trucks, an integral or adjacent air suspension system that uses height sensors, valves, and an electronic control unit (ECU) to manage ride height and stability. When the warning illuminates, the vehicle’s self-check sequence during startup usually reveals that at least one part of this chain is not meeting specification. In practice, this means the fault could reside in a sensor that misreads acceleration or deceleration, a corroded or loose connector, a faulty airbag module, a problem with the seat belt pretensioners or restraint circuitry, a valve or actuator in the air suspension, or even a low battery condition that leaves insufficient voltage for proper system function. The problem might be purely electronic, or it could be mechanical—an airbag or a component that has been damaged by wear, impact, or exposure to harsh operating environments.

In the field, the line between an airbag fault and a suspension fault can blur. A red warning that appears during operation might actually be signaling trouble within the suspension control logic, particularly in trucks equipped with advanced electronic control air suspension (ECAS) or similar closed-loop systems. Height sensors that measure wheel or axle position feed data to the ECU, which then commands air valves and actuators to adjust ride height. If a sensor drifts, a connector corrodes, or a fluid leak causes corrosion on sensitive terminals near a control switch, the ECU can interpret abnormal data and trigger a fault code. The result is a persistent warning light, even if the truck seems to run normally. This is why a diagnosis rooted in the actual principle of operation—understanding how the sensors, controllers, and actuators interact—is essential rather than simply replacing parts in a trial-and-error fashion.

The diagnostic path begins with careful observation of symptoms. A light that stays on after startup, rather than flashing briefly and then going dark, is a key sign that the system has detected a fault. In many trucks, the same warning can be tied to both airbag deployment readiness and suspension control readiness, especially when the two subsystems share sensing data or a common power supply path. A driver might notice changes in ride quality, such as uneven height, sluggish response to height adjustments, or unexpected changes in suspension behavior when changing load or road conditions. While these signs are informative, they are not definitive. They guide the technician to the likely culprits but must be corroborated with fault codes and a physical inspection of wiring and components.

To move from symptoms to specifics, the next step is to deploy professional diagnostic tools. A standard OBD-II scanner can reveal stored fault codes that explain why the warning light illuminated. In many cases, manufacturer-specific diagnostic interfaces—engineered to communicate with the ECAS or other advanced control systems—are required to read data streams, sensor outputs, and the live status of the ECU. The codes point to the general area of fault—whether it is a sensor signal problem, a communication fault between modules, a wiring rupture, or a failure in the control valve or module itself. In real-world scenarios, technicians sometimes encounter a hurdle: the diagnostic tool cannot establish a reliable connection at first. When that happens, it becomes a clue in itself. It might indicate a deeper electrical issue, a corroded terminal, or even a spurious data loop caused by a leak or contamination near a control switch. In one illustrative case, a Jiefang truck experienced a corrosion problem at the control switch caused by a nearby urea leak. This nearby fluid intrusion contaminated the electrical terminals, introducing resistance and erratic readings that frustrated initial connectivity attempts. It was only after cleaning and protecting the affected connectors that the diagnostic link stabilized and the fault codes could be read with clarity.

With fault codes in hand, the diagnostic process becomes more precise. The codes guide a systematic component test that proceeds from the simplest, most accessible elements to the more complex modules. Height sensors and the ECU form the core of the system’s perception—these are the components whose health most directly influences whether the suspension responds accurately to commanded changes in height or load. A technician will test the sensors by manually inducing height changes and observing whether the airbags respond as expected. If the suspension rises when commanded and falls when commanded, the core chain—sensor, ECU, air valves, and airbags—has a good chance of being functional. If, however, the sensors fail to change the system state or produce conflicting readings, the fault may lie in the sensor itself or the feed to the ECU.

Electrical integrity is the next critical frontier. Harnesses, connectors, and plugs must be inspected for signs of damage, wear, or chemical attack. Vibrations, temperature swings, and exposure to road spray render connectors vulnerable. The corrosion case mentioned earlier underscores how a seemingly distant issue—a leak from a nearby fluid line—can create a chain reaction that undermines terminal connections. Cleaning corroded terminals, tightening loose connections, and protecting the plugs from moisture become essential steps. In some instances, replacing a damaged connector or segment of wiring is unavoidable to restore a clean signal path. Attention to ground points is equally important; a poor ground can masquerade as an intermittent fault, complicating code interpretation and prolonging the repair process.

The control switch or remote valve block, which passengers may never see but which a technician interacts with directly, deserves particular scrutiny. The voltage at the switch can reveal layovers in the electrical supply that lead to erroneous valve operation. If a valve requires a specified voltage and the measured value sits at a fraction of that, the downstream effects propagate through the height-sensing loop and the ECU’s command logic, triggering fault codes. In the Jiefang example, diagnosing a 1.5-volt or 2.5-volt reading in a circuit that should see a robust 24-volt signal immediately flagged a suspect switch or a compromised wiring path. Replacing a damaged switch, repairing the wiring harness, or shielding the assembly from environmental exposure can restore proper operation. These checks are not just about fixing what is visibly wrong; they are about ensuring that every data point the ECU uses is trustworthy, because bad data leads to faulty decisions by the system and, ultimately, to unsafe vehicle behavior.

Once the faulty component is identified and repaired, the system must be reset, inspected for any additional fault codes, and revalidated. Clearing fault codes is not a cure in itself; it is the last step of the diagnostic cycle, following confirmation that the fault has been eliminated and that the system operates as designed. A recheck involves reapplying load, engaging the height-control logic, and verifying that the light remains extinguished under a range of operating conditions—from idle to full load and across different driving surfaces. It is essential to verify not only that the warning is gone but that the system remains stable and responsive to all commands. In practice, this means a careful test drive and, if available, a dynamic test that simulates typical loading scenarios to confirm that the suspension and safety systems work cohesively under real-world conditions.

This process, while technical, is part of a broader discipline that keeps critical safety systems reliable across a fleet. It is where everyday maintenance converges with high-stakes repair work. The driving principle is to understand the underlying technology well enough to avoid unnecessary part replacements and to ensure that every intervention preserves overall system integrity. The ECAS and similar systems, while advanced, still operate on a few simple truths: accurate sensing, robust communication, and reliable actuation. When any link in that chain is compromised, the warning light becomes the first indicator of a fault that could compromise safety. The diagnostic path outlined here—start with symptoms, extract fault codes, methodically test sensors and wiring, evaluate switches and valves, implement targeted repairs, and verify through thorough rechecking—is a practical template that aligns with the evolving realities of modern trucking. It respects the need for rigorous verification while acknowledging the realities of fieldwork, where moisture, corrosion, and mechanical wear are ongoing challenges.

Beyond the immediate repair, there is value in adopting a proactive maintenance mindset. Regular inspections of electrical harnesses, sealants around connectors, and protective measures for height sensors and control components can dramatically reduce the incidence of unexpected faults. Fleet managers and technicians increasingly focus on monitoring and early detection, using diagnostic data to anticipate failures before they trigger a warning light on the dash. This shift toward proactive maintenance is reflected in broader industry trends that emphasize reliability and lifecycle cost management for critical systems across fleets. It is not just about keeping a single truck off the road; it is about preserving the integrity of the entire operation, minimizing downtime, and maintaining safety margins that protect drivers and cargo alike. For readers seeking practical perspectives on maintenance strategies within private fleets, a discussion of ongoing maintenance trends offers concrete considerations and context for how these diagnostic practices fit into everyday operations. Private Fleets Trends in Trucking Maintenance

In the end, the message is clear: a Service Air Bag warning should be treated with respect and addressed with a disciplined diagnostic approach. The steps outlined here—recognize symptoms, read fault codes, test core components and wiring, evaluate control switches and valves, repair as needed, and verify comprehensively—provide a reliable framework for restoring safety and performance. Causality between a warning and a repair is rarely instantaneous; it is earned through meticulous analysis, careful testing, and a commitment to safety that does not cut corners. That commitment remains central to every repair story, whether the truck is a regional hauler facing the next load or a long-haul operator pushing through the night. The goal is not merely to turn off a light; it is to ensure that the system will deploy correctly when it matters most and that the suspension and restraint systems function cohesively to protect occupants in the event of a collision. The knowledge and practices referenced here draw on the principles of electronic control safety systems and the real-world realities of fleet maintenance, where insights from diagnostic work become the basis for safer roads and more dependable operation over the long haul.

For readers seeking deeper technical grounding, consult official resources that detail safety-system architectures, fault-code interpretation, and structured service procedures. These resources offer technical depth that supports the practical guidance outlined here, helping technicians translate codes and data into concrete, reliable repairs. External reference: https://www.example-external-resource.org/safety-system-standards

External resources and ongoing learning are essential, because technology in the trucking world continues to evolve. By committing to thorough diagnostics, careful repairs, and continuous maintenance awareness, drivers, technicians, and fleet managers can keep these critical systems functioning as intended. The road depends on it, and the people who work on these systems deserve reliable, accurate guidance that respects both safety and efficiency.

Final thoughts

In conclusion, the ‘Service Airbag’ warning on your truck is a critical indicator of potential malfunction within the airbag system. Understanding the causes of this alert, the consequences of neglecting it, and the steps required for accurate diagnostics and repairs are essential for maintaining safety and compliance within your operations. Addressing these alerts promptly ensures not only the safety of vehicle occupants but also upholds the integrity of your business’s logistics and transportation efforts.