Establishing a reliable tow truck service is paramount for various industries, including manufacturing, e-commerce, and construction. These sectors often require prompt responses to vehicle breakdowns or transport challenges, necessitating an efficient towing solution. This comprehensive guide will delve into crucial aspects of running a tow truck service, focusing on legal compliance, equipment selection, technological integration, staffing strategies, and effective marketing. Each chapter will equip businesses with the necessary knowledge to optimize their towing operations, ensuring superior customer service and expanding their market reach.

The Road to Compliance: Building a Trustworthy Tow Truck Service Through Law, Licensing, and Safety

Compliance is not a ceremonial checkbox in tow operations; it is the quiet backbone that makes a service reliable, scalable, and trustworthy. When a vehicle fails and a driver is called to assist, speed matters, but so does legality, safety, and accountability. A tow business without a robust compliance framework invites more than fines. It risks reputational damage, gaps in insurance protection, and fractured customer trust. The path ahead is not a maze of rules to endure, but a design of routines that translate regulation into predictable, high-quality service. The following emphasis on legal and regulatory practice shows how to align every part of the operation with the expectations of regulators, lenders, insurers, and customers alike. This alignment is not about stifling growth; it is about creating a durable platform for growth that can weather accidents, market shifts, and expansion into new regions.

Vehicle technical standards form the first shield for road safety and service reliability. As of November 2023, nationwide updates raised the bar for what counts as roadworthy in a tow fleet. Tow trucks must pass a comprehensive inspection before any licence is issued or renewed. The criteria touch multiple axes: structural integrity, braking performance, lighting, towing apparatus, and overall mechanical condition. Regulators expect no shortcutting of these checks; the consequence of noncompliance can be denial of licensing or immediate removal from service. These rules reflect a growing recognition that towing operations involve complex loads, dynamic environments, and the potential for cascading failures if even a small component is neglected. For a business, this means more disciplined maintenance planning, better documentation, and a mindset that views inspections as safeguards rather than annoyances. The historical note that a tightening occurred in November 2022 underscores a shift toward proactive quality assurance. In practice, that means treating every upcoming renewal as a deadline to verify the vehicle’s health rather than a chance to push the risk downstream. A well-prepared fleet keeps a visible, auditable trail of frame integrity, hydraulic lines, braking systems, lighting, reflectors, tires, and the mounting of tow gear—everything a regulator expects to see when a vehicle enters service.

Driver qualifications and licensing form the human pillar of safety. Operators must hold valid commercial driver licenses appropriate for the vehicle class and load. Beyond the license, regulators require knowledge of vehicle maintenance, cargo securement, and safe towing practices. Regions vary in the exact training modules, but the universal standard is clear: competence must be demonstrated through formal assessment and ongoing education. For a small operator, that translates into a structured onboarding sequence, periodic recertification, and a culture in which drivers can raise safety concerns without fear of penalty. Carriers that invest in continuous training—covering basic mechanics, roadside etiquette, and the specifics of securing diverse loads—tend to see fewer incidents, quicker recoveries, and better overall fleet health. The human element is where legal compliance becomes practical reliability on the ground, and the best operators embed safety into daily routines rather than relegating it to annual reviews.

Business licensing and permits define the legal perimeter of the operation. A Road Transport Operating Permit acts as a banner of legitimacy, granted only after a thorough demonstration of compliance with technical, financial, and operational standards. The permit process typically involves an application, proof of vehicle inspections, evidence of adequate insurance, and demonstration that the company has established internal safety management and organizational controls. In some jurisdictions, cross-border tasks add layers of complexity under measures designed to coordinate traffic and commerce across borders. For example, certain regional frameworks may require additional permits when services extend beyond domestic borders into neighbouring provinces or neighboring jurisdictions. For operators pursuing regional service lines, a precise map of required permits is essential; overlooking a single flag can stall growth and invite penalties. This is where compliance becomes a growth enabler: each approved permit constructs a predictable boundary within which expansion can occur with confidence. The practical outcome is that licensing is not a barrier to scale but a gate that protects the business, customers, and workers alike.

Safety and operational compliance bind everything together. Firms must implement robust safety management systems that cover routine maintenance, accident reporting, and driver training. Vehicles used for heavy-duty towing, including large semi-trailer configurations, must be equipped with dynamic monitoring devices and connected to a central monitoring platform for real-time oversight. This is not surveillance for its own sake; it is accountability that improves response times and reduces the risk of miscommunication during emergencies. The real-time visibility afforded by these systems translates into measurable gains: quicker dispatch decisions, better route choices, and fewer delays caused by uncertain vehicle status. For fleets that handle heavy units, the emphasis on continuous monitoring becomes even more prominent, ensuring that heavier loads are tracked, maintained, and inspected with heightened scrutiny. The result is a disciplined cadence of checks that translates into safer recoveries, clearer customer updates, and a lower probability of service interruptions caused by avoidable failures.

Turning regulatory requirements into actionable routines requires deliberate design. Start with clear standard operating procedures that specify who does what, when, and how. Maintain a centralized log of inspections, maintenance events, training sessions, incident reports, and renewals. Designate a compliance lead or safety coordinator who reviews records, coordinates audits, and keeps the team aligned with evolving rules. This is not bureaucratic padding; it is the engine that drives professional customer experiences. When drivers understand that every task is part of a traceable, auditable process, confidence grows among customers who rely on timely help and transparent pricing. The bridge between legality and service quality is trust, and trust is built through consistency and verifiable processes. In practical terms, this means scheduling monthly safety briefings, documenting near-miss reports, and conducting quarterly reviews of equipment and procedures.

The broader value proposition of compliance extends into efficiency and growth. Modern tow operations increasingly blend regulatory discipline with digital platforms that streamline dispatch, scheduling, and documentation. Real-time dispatching, GPS-enabled route optimization, and customer communication tools become meaningful only when the data they generate is trustworthy. A compliant operation is less exposed to downtime from paperwork and more capable of scaling as demand expands into new corridors. In short, legality and efficiency reinforce one another and enable a service that customers can rely on in moments of crisis. The fusion of rule-based discipline with data-driven processes creates a resilient business model that can adapt to regulatory changes, market volatility, and evolving customer expectations without losing speed or quality.

Finally, operators should stay connected to the evolving regulatory landscape. Regulations shift as technology, vehicle design, and traffic patterns change. A proactive posture means scheduling periodic reviews of policies, training modules, and equipment standards, and seeking guidance from regulators or industry associations when uncertainties arise. It also means recognizing that some regions carry unique requirements for cross-border activity. For operators near borders, understanding Cross-border regulatory issues is essential. Cross-border regulatory issues is a focal point for planning expansion or shared services across jurisdictions, ensuring that growth never outpaces compliance. As new rules surface, the best operators revisit risk assessments, adjust SOPs, and re-verify that every truck, driver, and permit aligns with the latest expectations. This ongoing vigilance turns compliance from a static obligation into a competitive advantage, enabling a tow service to deliver rapid, transparent, and lawful support when customers need it most.

The upshot is straightforward: compliance is not a hurdle to growth but its foundation. A tow service built on documented standards, trained personnel, and transparent processes reduces risk and increases reliability. It invites customers to choose your team with confidence, knowing that their vehicle will be handled by people who understand the rules as well as the roads. The evidence from industry practice shows that when compliance is paired with digital capability, operations run more smoothly, customer satisfaction rises, and margins improve. The legal framework may seem dense, but its structure creates a stable operating envelope within which a tow business can innovate, differentiate, and scale. For operators who want to see how regulation can serve a service mindset, the real-world lesson is simple: let rules inform routines, and routines become the customer experience.

For further reading on current standards and how they shape day-to-day practice, the Security and Business Development Council’s analysis offers practical guidance on new regulations for the tow truck industry. https://www.sbdc.org/blog/new-regulations-for-the-tow-truck-industry

The Right Rig for Every Road: Selecting Vehicles and Gear to Power a Safe, Efficient Tow Truck Service

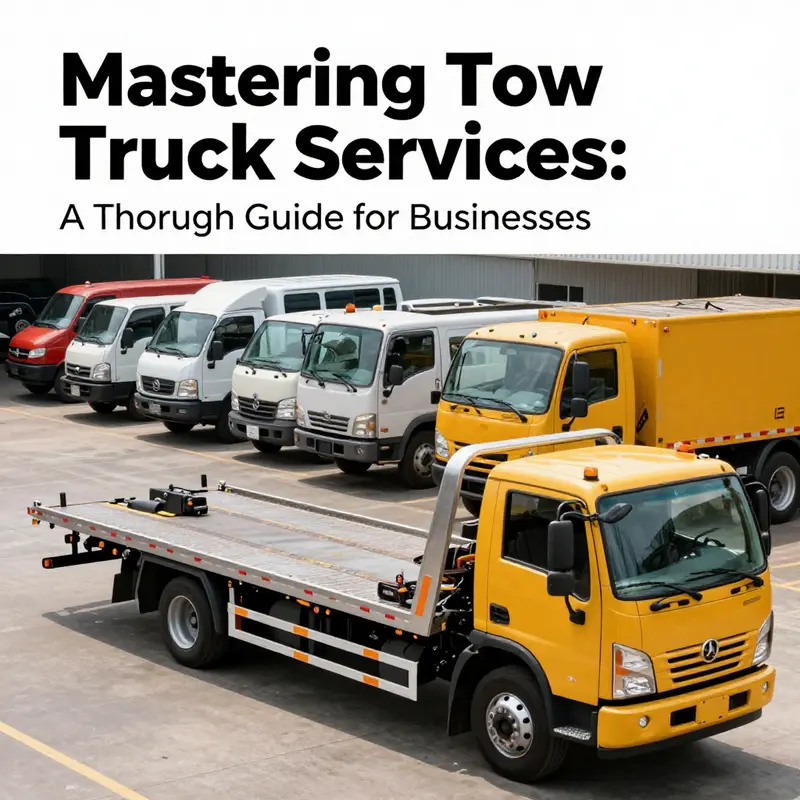

Choosing the right vehicle and the right gear is not a secondary decision in a tow truck service. It defines the reach of your operation, the safety of every recovery, and the speed with which you return customers to the road. In this line of work, the road environment dictates the core capabilities, while the design and equipment of your fleet translate capability into dependable performance. The goal is to balance maneuverability, payload, and resilience so that your team can handle the everyday bustle of urban incidents and the demanding recoveries that occur on highways and remote stretches alike. As you begin, picture your service footprint: the kinds of calls you most often accept, the typical distances you cover, and the weather and traffic conditions you contend with. That vision should guide every choice you make about the chassis, the tow apparatus, and the auxiliary gear that joins them. The choice is not just about what is possible; it is about what is prudent, reliable, and scalable as you grow your business.

In urban environments, the logistics of navigation and rapid dispatch call for a compact, agile platform. A flatbed that fits through narrow streets, with a tight turning radius and straightforward loading procedures, helps you respond quickly to multiple small-vehicle incidents in crowded districts. The objective here is efficiency without compromising safety. In contrast, highway operations demand a markedly different kind of capability. Heavy-duty chassis with substantial towing capacity, robust hydraulic systems, and strong stabilizers become essential when you must manage larger vehicles, complex recoveries, or long-haul transport between accident sites and repair facilities. A mounting system that accommodates a rotating crane or high-capacity winch can make the difference between a successful recovery in adverse conditions and a prolonged roadside operation. Rural and semi-urban routes present their own demands, with variable pavement, limited service infrastructure, and extended response times. A fleet that combines durable components with reliable remote diagnostics can minimize downtime and ensure you can reach more customers when they truly need help.

Once you define the service environment, the next layer is matching equipment to the vehicle you tow. For light-duty vehicles—sedans, small SUVs, or motorcycles—a simple, high-strength tow bar or short-length strap with clear load points can be enough for short moves or secure repositioning within a lot. The emphasis here should be on secure mounting, stable attachment points, reflective detailing for visibility, and anti-slip features to reduce the risk of slippage during transport. For heavier vehicles or longer hauls, the configuration shifts decisively toward a rigid tow bar or a heavy-duty drawbar with reinforced mounting points. The rig must offer stable contact with the vehicle’s structural points, with a rated capacity comfortably exceeding the target vehicle’s weight by a safety margin—an industry practice that should be set at least 25 percent above the heaviest anticipated tow. This margin provides breathing room for braking dynamics, surface conditions, and any incidental shifting during transport. Beyond the core tow bar, the selection of chains, hooks, cables, and auxiliary devices matters as well. Regular inspection and replacement of worn components are non-negotiable; a single worn link or stretched cable can derail a recovery and endanger operators. Lighting, reflectors, and warning beacons must be chosen to ensure visibility in dusk or night operations, both for other drivers and for the safety of your team at the scene.

Maintenance and reliability are inseparable from the initial hardware choice. Tow trucks operate in high-stress environments where vibration, weather exposure, and heavy loads test every component. A disciplined maintenance program that covers hooks, chains, cables, hydraulics, and the chassis will deliver a longer, safer service life. Modern fleets increasingly rely on digital health monitoring to flag potential problems before they become failures. Telematics-enabled platforms and connected diagnostic tools can provide real-time health data, alert for tire wear, hydraulic pressure fluctuations, and abnormal temperature readings, and schedule preventive maintenance around actual usage patterns. This data-driven approach reduces downtime, improves dispatch reliability, and helps you plan capital expenditures more accurately. It also supports a more transparent relationship with customers, who appreciate predictable service availability and fewer unexpected delays.

Technology is not simply about monitoring or dispatch; it is a partner in the actual operation of the equipment. Real-time data about battery status for electric or hybrid configurations, the efficiency of winches under load, and the response characteristics of lifting arms at varying temperatures all feed into safer, faster recoveries. When you evaluate whether to add electric or hybrid units to your fleet, you are not just weighing operating costs; you are considering the broader capabilities to deliver on time, across diverse conditions. A forward-looking approach to equipment should also consider maintenance support—factory or manufacturer networks that can supply parts quickly, provide technical training, and offer service reminders aligned with your usage. In the end, the most cost-effective choice is the one that keeps your trucks on the road longer and reduces the risk of on-scene failures.

Regulatory compliance sits at the heart of every selection. Vehicles and their equipment must meet federal standards and local regulations, which govern emissions, safety features, and the secure handling of towed loads. Adhering to EPA emission standards, Federal Motor Vehicle Safety Standards, and state or provincial rules reduces exposure to fines and strengthens your license to operate. An investment in compliant equipment is an investment in long-term viability, especially as enforcement and standards continue to tighten. The broader implication is that you should prioritize brands and configurations with proven track records for durability and serviceability. The goal is to avoid a glossy initial price that inflates maintenance costs or causes frequent downtime due to parts availability. A reputable supply chain and a robust after-sales network translate into steadier uptime and better customer confidence over time.

The decision process is not merely a matter of selecting correspondingly capable hardware; it also involves how the fleet integrates with dispatch, training, and safety protocols. A well-chosen vehicle and gear set a baseline for performance, but the operational discipline of your team determines whether that performance translates into reliable service. Operators who understand mechanics and safe towing practices can adapt to different vehicle types and payloads with greater competence, reducing the likelihood of damage to recovered vehicles or injuries on the roadside. Training programs should cover the specifics of each equipment configuration, the importance of proper hookup procedures, and situational awareness at accident scenes. Performance monitoring tools can quantify response times, loading efficiency, and customer feedback, offering a clear view of how equipment choices influence day-to-day outcomes. In a mature operation, the data from these tools informs not only maintenance schedules but also future procurement decisions, guiding you toward configurations that deliver measurable improvements in safety, speed, and customer satisfaction.

As you weigh a broader strategic path, consider how digital workflows reshape the economics of equipment and people. Digitalized intake, on-scene verification, and post-service validation reduce miscommunication and rework. A consistent pattern across high-performing fleets is the alignment of hardware choices with digital processes that track every step of a tow—from initial request through handover to the customer. Such alignment minimizes human error and builds trust with customers who expect clear updates, transparent pricing, and timely service. The lessons from industry-wide improvements emphasize that the best equipment is not just physically capable; it is integrated into a system that delivers reliable, repeatable results.

To add a practical frame for ongoing improvement, study how markets are modeling equipment and fleet expansion. For example, one path to enhanced capability involves exploring electric or alternative-fuel configurations as part of a long-term plan. Electric-mobility considerations must include not only the vehicle’s range and charging needs but also how the equipment integrates with load handling and uptime. The broader takeaway is that equipment decisions should align with your service strategy, financial plan, and regulatory compliance. Look for configurations that balance upfront cost with long-run savings in fuel, maintenance, and downtime, while ensuring you can meet the demands of your service environment. A well-considered mix of light- and heavy-duty units—tailored to local conditions and supported by strong maintenance and parts networks—will position your tow truck service to respond rapidly and safely to whatever the road throws at you.

For further context on how digitization and adaptable fleets shape the market, you can explore resources on electric trucks market entry in Canada. This internal reference discusses how operators balance technology adoption with regulatory and operational realities: electric trucks market entry in Canada.

As you finalize vehicle and equipment selections, remember the underlying principle: every piece of gear is a tool to deliver safety, speed, and trust. The right combination will not only meet today’s demands but also adapt to tomorrow’s changes in route patterns, regulatory expectations, and customer needs. With disciplined maintenance, strategic use of data, and a clear vision for how your fleet fits into a broader service ecosystem, your tow operation can achieve a durable competitive edge that translates into steady growth and sustained customer confidence. For formal guidance on equipment standards and safety considerations, consult the national guidelines and regulatory resources available from the relevant safety authority. External references can be found at https://www.nhtsa.gov.

Toward a Smarter Tow: Orchestrating Real-Time Dispatch, Maintenance, and Customer Care Through Technology

Technology has moved from a helpful add-on to a core operating rhythm for tow truck services. In a business built on speed, safety, and trust, the ability to see every job, every mile, and every interaction in real time changes not only how fast you respond but how consistently you perform. This chapter threads together dispatch intelligence, predictive maintenance, digital workflow, and customer relationship discipline into a single, coherent operating system. The aim is not to replace your people but to empower them with data, visibility, and tools that make every tow safer, every ETA more accurate, and every customer interaction more confident.

Real-time tracking and dispatch software sit at the heart of modern tow operations. When a call comes in, the system evaluates proximity, driver availability, truck type, and current weather or traffic conditions to assign the closest capable unit. The result is faster response times and a transparent customer experience. Customers increasingly expect to see a progress indicator, not just a rough promise. Digital platforms that translate a queue of requests into a live map of active units allow a dispatcher to reallocate resources on the fly if a new incident emerges or if a driver encounters a delay. The tangible benefits show up as reduced idle time, improved on-scene handling, and a higher likelihood of getting a vehicle to safety before more damage occurs. The real-time lens also supports performance discipline inside the fleet. Dispatch data becomes a feedback loop: late starts or lengthy on-scene times are traced, analyzed, and corrected with coaching or routing refinements. This is not about micromanaging every move but about ensuring consistency in how quickly and safely teams respond.

The transparency that real-time dispatch provides extends beyond the office. A customer can be apprised of an accurate ETA and updated automatically as conditions shift. This reduces the number of calls in which drivers must repeat or justify delays, which in turn lowers the likelihood of miscommunication. When a customer can track their tow truck on a map and see an estimated arrival, they feel informed and respected. A culture of clear communication begins to permeate the entire operation—from the initial call to the moment the vehicle is secured and the customer signs off on the job. The smoother that handoff, the more likely the client will become a repeat caller and a source of referrals.

Beyond speed, these systems fundamentally improve safety. Real-time tracking makes it easier to observe routes, monitor driving patterns, and intervene when a vehicle is taking unnecessary risks. Telematics — the data-enabled observance of vehicle health, speed, braking, and idle time — turns routine maintenance into a proactive program. You learn which routes or loads push hydraulic systems beyond their normal envelope and schedule preventive care before a breakdown disrupts a critical recovery. A fleet that treats maintenance as predictive rather than reactive runs more reliably and costs less in unplanned downtime. The aim is to align maintenance windows with dispatch realities, so a truck is not pulled offline at a moment that leaves a customer stranded.

If the dispatch board is the nervous system, then digital checklists and mobile work orders are the reflexes that keep the system accurate and safe. Digital checklists break complex jobs into precise, repeatable steps. When a technician secures a vehicle on a flatbed, inspects for payload stability, or verifies insurance details, each step can be logged with time stamps, photos, and notes. The uniformity of digital workflows reduces human error and makes audits straightforward. For example, a standardized sequence for accident recovery ensures that every carrier strap is properly tightened, every light is checked, and every load is documented before departure. This level of accountability is particularly valuable when dealing with insurance claims or post-service evaluations, where documentation can determine the pace and outcome of a settlement.

Mobile work orders reinforce this discipline by turning every crew into a field data entry point. Dispatchers no longer depend on handwritten notes or memory to track task status; instead, a technician can pull up the job, confirm required equipment, request a part, or report a complication with a few taps. This immediate capture of information creates a living record that travels with the job as it moves through the recovery cycle. The consequence is greater consistency from one job to the next and a clearer path for training new staff. A digital workflow approach also opens doors to scalable growth. As your business expands into new service areas, the same standardized processes can be deployed with minimal adjustment, preserving service quality while you add capacity.

Customer relationship management (CRM) tools enter this ecosystem as the memory and voice of the business. A cloud-based CRM stores client preferences, past services, and payment methods, enabling tailored communications and predictable experiences. A driver can add a note about a recurring issue for a vehicle type and tens of thousands of future touches can be executed with a personalized cadence. Billing becomes more transparent when customers can review the service history, see a clear breakdown of charges, and understand what to expect in the future. Loyalty programs or incentives, when used thoughtfully, can convert episodic emergencies into ongoing partnerships. The strength of CRM lies not in selling more services but in strengthening trust and continuity with each customer.

To be effective, technology must be integrated with people and processes, not installed as a standalone gadget. The best fleets treat digital tools as extensions of their team rather than replacements for it. Training becomes ongoing rather than a one-time event. Operators learn how to interpret telematics dashboards, how to respond to automated alerts, and how to communicate confidently with customers during a tow. This requires a management culture that values data literacy, meticulous record-keeping, and proactive communication. With the right training, a dispatcher can anticipate bottlenecks, a technician can escalate a hazard before it worsens, and a customer service rep can manage expectations with a consistent, truthful narrative.

The practical architecture of a technology-enabled tow service hinges on thoughtful integration. Real-time dispatch must connect with maintenance data so parked vehicles do not stay offline longer than necessary. Digital checklists must sync with the mobile work orders so the status of a job mirrors the actual work performed on the ground. The CRM must reflect completed jobs in near real time to avoid miscommunications and to support effective follow-ups. When these systems are designed to feed one another, the entire operation becomes a single, self-correcting organism. This is how a small fleet scales into a larger one without sacrificing reliability or customer experience. And while the tech stack plays a critical role, the governance around data—privacy, accuracy, and security—shapes how much value you can extract from it.

There is a meaningful opportunity in recognizing that technology does not stand alone; it amplifies the capabilities of your people. A seasoned driver who understands the logic of routing and the significance of on-board checks can become more effective when equipped with a digital checklist that guides every action and secures compliance. A dispatcher who can visualize the entire fleet’s status and reallocate assets with one click will operate with the confidence that every decision is data-informed. A customer service representative who can present a transparent, up-to-the-minute story about a tow is empowered to build trust rather than merely react to problems. In practice, this integrated approach creates a stability that clients notice—the difference between a driver who shows up and a team that shows up prepared, on time, and ready to help.

As this chapter illustrates, the future of tow services lies in harmonizing dispatch intelligence, predictive maintenance, digital workflows, and customer engagement into a cohesive system. The result is a safer fleet, a faster response, and a customer experience that feels effortless even in stressful moments. A well-implemented digital backbone does not erase human judgment; it augments it. It gives managers the leverage to plan, train, and innovate while protecting the core elements that define a reliable tow service: safety, speed, and service with integrity. For operators who embrace this convergence, growth follows not from chasing novel tools but from knitting technology into the daily work of the road, the yard, and the call center. The gains show up as fewer breakdowns, shorter times to assist, stronger compliance, and more predictable, positive interactions with every client stepped into a difficult moment.

Notably, the literature on digital transformation in auto and tow industries emphasizes the same pattern: move from isolated tools to an integrated operating system that spans intake, fieldwork, and follow-up. In practice, this means choosing platforms that speak to each other, investing in training that makes those platforms intuitive, and maintaining a governance standard that protects data quality and customer privacy. For readers exploring deeper case studies or implementation details, a closer look at the broader landscape of private fleets and their maintenance practices can provide useful context and actionable insights. See the discussion on Private Fleets Trends in Trucking Maintenance for more on how fleets balance routine care with evolving technology.

External resource for further reading: https://www.samsara.com/solutions/telematics-for-towing-and-transport/

Mobilizing the Crew: Staffing, Training, and Readiness for a Tow Truck Service

Winter tests more than the road. It tests the people who respond to distress, the processes that translate a phone call into a safe, timely arrival, and the culture that keeps all of it moving when conditions are at their worst. In a tow truck operation, staffing and training are frontline competencies that determine whether a stranded motorist gets help within minutes or within hours. The winter season faced by Finish Line Towing in southern Wisconsin offers a frame for readiness: when calls surge from hundreds to thousands in a day, the difference between a service that barely survives and one that thrives hinges on how teams are assembled, prepared, and guided by routines. The goal is a system that scales smoothly, preserves safety, and preserves the human element that customers remember long after the tow is completed. In such a system, staffing is a strategic choice, not a calendar checkbox, and training is a living practice that evolves with weather, road conditions, and the mix of vehicles on the road.

The core idea behind effective staffing is anticipation. A robust staffing model starts with a clear understanding of demand patterns and capacity. In extreme conditions, demand can spike dramatically, and the operation must respond with a plan rather than haste. The all-hands-on-deck mentality describes a deliberate design: build redundancy into every role, not as a burden, but as a buffer against fatigue, miscommunication, and delays. It means scheduling additional crew members even on days off or during expected peak periods, so the team can stretch or reallocate resources as the day evolves. The payoff is faster response times, safer operations, and a steadier stream of good news to customers already stressed by a breakdown in bad weather. When weather worsens, it is not only the truck that must be ready; the entire crew must adapt quickly to the changing landscape of calls, locations, and vehicle types.

The dispatch arena is where readiness and realism meet. An eight-person team facing a deluge of calls must keep communication precise and decisions decisive. Real-time dispatching requires a blend of fast software-enabled routing and human judgment about priorities, traffic, and safety risks. In peak moments, dispatchers become force multipliers: they assign the closest available units, balance workloads to avoid burnout, and maintain a calm, professional line of communication with drivers and customers. Training for dispatchers goes beyond answering phones and includes crisis management, prioritization under pressure, and the art of keeping everyone informed without overwhelming them with information. This discipline shines when a thousand calls must be managed: clarity becomes instinct, so there is no scrambling, only orderly execution.

Safety anchors staffing decisions in every weather scenario. The winter environment introduces hazards that demand heightened awareness, disciplined risk assessment, and strict adherence to operating boundaries. A rule like ‘We will not pull over or do anything on the side of the freeway unless we can be totally on that side of the white line’ becomes a procedural standard. It guides when and where a tow can occur and under what conditions teams may continue. Regular drills that simulate snow, ice, low visibility, and active construction zones help crews translate this rule into automatic behavior. The focus is not only on maneuvering a truck or winching a vehicle but on recognizing cues that signal risk—slick ramps, changing wind gusts, or the approach of a fast moving semi. The training must embed a shared mental model so that every driver, dispatcher, and supervisor can act decisively, consistently, and safely when the pressure is highest.

Training expands beyond recovery mechanics to the nuances of service delivery. Drivers encounter a spectrum of vehicles: electric models with charging window constraints, SUVs with varying ground clearance, and luxury cars that require gentler handling. Training blends hands-on practice with theory, using simulation tools to rehearse complex or dangerous scenarios without risk. Technical skills are essential, but customer service remains vital in a field where emotions run high and trust is earned through conversations as well as outcomes. Clear explanations about timing, pricing, and what customers should expect during a tow build confidence and reduce friction. This holistic approach creates technicians who can handle the full arc of a roadside incident—from the initial call through post-service follow-up—and stay composed in stressful moments.

Technology and data reinforce the human elements. Digital platforms now integrate online requests with real-time dispatch, GPS tracking, and customer communication. AI-enabled image recognition and digital tracking can verify safety steps, detect anomalies, and provide a transparent record of the service journey. The goal is to augment human judgment, not replace it: data highlights coaching opportunities, and dashboards make performance visible to managers and technicians. When crews see how quickly they respond, how their routes compare, and how customers rate their service, the incentive to improve becomes concrete. A culture of improvement emerges when teams observe, reflect, and adjust together.

The value of staffing and training shows up in retention and morale as much as in metrics. Investing in people is a strategic practice that yields lower turnover, better safety, and stronger customer loyalty. This starts with thoughtful recruitment and onboarding, then expands into ongoing development, mentorship, and clear pathways to leadership. A robust program treats every employee as a long-term asset, reinforcing the idea that growth in a tow service is a collective journey. When workers feel supported, they perform with more confidence, communicate more effectively with customers, and take fewer unnecessary risks on the road. Leaders who cultivate this culture align compensation, recognition, and advancement with demonstrated safety, reliability, and customer satisfaction.

Looking ahead, readiness is a moving target. Weather, traffic dynamics, and vehicle technology evolve, and so must staffing plans and training curricula. The strongest operations embed learning into daily routines: shift-change huddles, brief safety refreshers, and regular debriefs after difficult incidents. This cadence keeps skills sharp and attitudes aligned with a safety-first, customer-first philosophy. The result is a workforce that can pivot quickly—drivers who can shift between standard tow work, incident response on highways, and load management for storage or deliveries—while maintaining courtesy and care for customers in distress. The long-term payoff is a resilient organization that can withstand storms, maintain service levels, and earn trust in a competitive market.

For readers seeking concrete avenues to strengthen staffing and training, design for readiness: build a pipeline that blends flexible scheduling with cross-training, establish a dispatch culture that prizes clarity and calm, and weave safety into every drill and every route. Foster a learning environment where feedback is welcome, metrics guide coaching, and success stories are shared across the team. The human core of a tow service—drivers, dispatchers, and leaders working in harmony—transforms cold, hazardous roads into safer passages for motorists in need.

External resource: Wisconsin DOT – Winter Storm Preparation. See https://www.wisconsindot.gov/Pages/Transportation-News/2024/12-2024-winter-storm-prep.aspx

Tow Truck Service Marketing Mastery: Building Trust, Speed, and Lasting Customer Loyalty

Marketing and customer service are not afterthoughts in a tow truck business; they are the front line of reliability in a high-stress moment. When a driver’s car breaks down on a busy highway or a fleet manager faces a roadside incident, the first impression often comes from a dispatcher message, a website, or a driver’s calm voice on the phone. In a market where dozens of tow options might appear within minutes, your brand must promise something clear: rapid response, transparent pricing, and professional care for the vehicle and the owner. That promise becomes your marketing message, but it also sets the standard for every interaction. The most successful operators weave marketing and service into one continuous experience. They don’t shout about their capabilities once in a Google ad and then neglect the customer in the dispatch lane. They craft a consistent journey from first touch to post-service follow-up that earns trust, repeat business, and referrals.

Digital channels now carry the heaviest weight in this journey. A modern tow truck service should own a simple, fast-loading website that explains services, hours, and pricing in plain terms. It should offer online booking, or at least a rapid contact option, so a stranded motorist can reach help with a tap, not a chain of calls. SEO matters here, because a customer in distress often searches with urgent phrasing like tow truck near me or emergency towing. Responsive design is essential; an interface that works as well on a phone as on a desktop reduces friction when speed is most needed. In addition, a lightweight content strategy—tips on vehicle safety, winter driving checks, or what to expect during a tow—builds credibility and shows you understand the owner’s anxiety and questions. PPC campaigns can complement organic traffic, placing your service in front of people who need help now, while careful landing pages convert clicks into booked trips by clarifying what happens next and how pricing is determined.

Local listings help people find the tow truck service when they need it most. A complete Google Business Profile with correct hours, service areas, and contact information makes your operation the obvious choice in emergency searches. Reviews form the social proof that powerfully reinforces confidence; a steady stream of recent, thoughtful feedback tells potential customers that you stand by your promises and that you respond to concerns promptly. The interplay between online reputation and offline performance is real: a dispatcher who communicates clearly during a tow can turn a one-time customer into a regular partner who flags your number for future incidents and for the fleet manager who needs regular service.

Clear pricing is a cornerstone of trust. If you publish transparent rates, surcharges, and the expected range for common scenarios, you cut skepticism and reduce phone time spent negotiating. Customers appreciate a system that explains why a price can vary with distance, time of day, or vehicle type, and then follows through with receipts that itemize labor, disposal, or storage charges. You can reinforce this trust by displaying updated service-level commitments, such as response times or ETA windows, on your site and in your app. The more a customer sees that you operate with predictable reliability, the more likely they are to choose you again and to recommend you to others in their network.

Beyond individuals, business-to-business relationships with fleets, rental agencies, and local dealerships create steady demand. Marketing to fleets is different from marketing to stranded drivers: it rewards reliability, predictable billing, and easy, centralized invoicing. You can offer commercial packages with volume pricing, account management, and a straightforward process for reporting and documentation after each call. This isn’t about slick ads alone; it’s about reducing friction for the operator who has to manage roadside incidents across dozens, or hundreds, of vehicles. A strong brand emerges when you pair professional appearance with consistent service across every touchpoint—dispatcher scripts that calm anxious callers, technicians who respect the vehicle and the location, and a driver who leaves the scene with the owner feeling informed rather than overwhelmed.

Customer service must be proactive, not reactive. Train dispatchers and drivers to communicate simple, reassuring updates—arrival times, what the tow entails, any required steps, and what the owner should expect next. A well-timed text or app notification can relieve the stress of waiting. When your team makes the service experience predictable, you begin to convert fear into confidence. A post-service survey, even a brief one, signals that you care about improvement and give customers a path to voice concerns. Handling negative feedback gracefully—acknowledging the issue, explaining what went wrong, and outlining corrective steps—turns a complaint into a learning moment and a chance to demonstrate accountability. In parallel, cultivate a public online presence that welcomes feedback and shows tangible action, because reputation is a living thing in the digital age.

Technology underpins all of these efforts. A modern tow operation uses digital platforms to blend dispatch, GPS, and customer communications into a single flow. Real-time visibility lets the customer track the technician’s progress and receive updates as the route shifts due to traffic. Back-end analytics guide decisions about staffing, routing efficiency, and service priorities. For example, if the data reveals a higher demand for battery jump-starts during a cold snap or a spike in storage fees during peak season in a particular area, you can adapt pricing, promotions, and resource allocation accordingly. The goal is not complexity but clarity: every interaction should feel straightforward to the customer while giving your team the data it needs to plan and improve.

Marketing, service, and operations should align with larger industry trends. When you consider the broader economic climate and shifts in the trucking sector, you can position your service to meet emerging needs. These shifts align with broader economic-trucking-trends that influence how fleets choose partners, how quickly individuals search for help, and where investment flows. The better you understand those trends, the more you can tailor your value proposition—faster response, transparent pricing, and reliable, courteous service—to the realities of your service area. The result is a brand that feels both local and connected to a bigger ecosystem, which resonates with both roadside customers and commercial clients.

Ultimately, the market rewards operators who pair robust customer service with clear, value-driven marketing. Your communications should reflect what you deliver: speed when time is scarce, clarity when questions arise, and care for people who are dealing with stressful moments. A well-built marketing plan does not replace service quality; it amplifies it, turning satisfied customers into advocates who broadcast your reliability to others through referrals and online reviews. The interplay between efficient dispatch, empathetic communication, and transparent pricing creates a cycle of trust that professionals in the field recognize as the strongest free marketing you can invest in.

Readers seeking deeper guidance can find practical frameworks in industry resources. See the BBB resource for a structured approach to marketing in tow services: BBB Tow Truck Marketing Strategies.

External resource: https://www.bbb.org/small-business-resources/tow-truck-business-marketing-strategies

Final thoughts

In conclusion, establishing a successful tow truck service requires a multifaceted approach, focusing on legal compliance, the right equipment, technological integration, expert staffing, and effective marketing strategies. By adhering to best practices across these areas, businesses can not only meet the immediate needs of their clients but also position themselves for long-term growth in a competitive market. With dedication and the right resources, your tow truck service can become an invaluable asset to the industries you serve.