Organizing your service truck is not just a matter of aesthetics; it is a critical element in maximizing efficiency for businesses such as manufacturing, retail, construction, and logistics. In an industry where time equates to money, the need for an effective framework to manage tools and supplies becomes paramount. This guide will delve into five essential chapters, each focusing on key strategies to transform your truck into a well-organized space. From starting with a complete reset to maintaining order regularly, each section will provide actionable insights tailored to help small business owners, fleet managers, and service providers alike enhance their operational effectiveness.

Starting Fresh: The Complete Reset That Sets Your Service Truck Up for Speed, Safety, and Smooth Service

The inside of a service truck often reflects the way its operator thinks about work. A cluttered cab and a crowded back bay can slow you down, create frustration, and even invite safety risks on the road. The core idea of organizing begins not with buying more organizers, but with a complete reset. This reset is a deliberate, methodical clearing out that reveals what space you truly have, what you actually need, and how you want to move through a day with fewer detours. It’s not just about tidying up; it’s about reshaping your entire workflow to align with how you work—where you stand, what you grab first, and how you balance weight and access as you drive and service on site. When you start with a clean slate, you unlock the ability to design a system that makes sense for you, your tools, and the kinds of calls you handle most often. The reset is the decisive moment that separates improvisation from intention, and it sets the direction for everything that follows.

Begin with a hard reset by emptying the truck completely. Remove every tool, every container, every spare part, and every piece of equipment. The cargo bay, the drawers, the overhead compartments, even the top shelves—all must be emptied so you can see the interior as if you’re looking at it for the first time. This is not a shuffle of items; it’s a thorough declutter that gives you the freedom to evaluate each item on its own merit rather than its historical place in your rig. As you pull items out, take a moment to acknowledge what you actually use and what tends to sit unused. If a tool hasn’t touched your hand in months, it’s worth questioning whether it remains essential. If a duplicate exists, ask which version serves better in your typical workflow. If an item is outdated or no longer functional, set it aside for replacement or retirement. The act of decision-making here matters as much as the physical act of moving items, because every item you keep must earn its position in your truck.

With the truck emptied, you now see space with fresh eyes. This is when you evaluate the interior geometry: where space exists that you hadn’t noticed before, what vertical real estate can be exploited with the right racks, and where you can place zones that reflect your daily routine. It’s helpful to picture a typical service call from arrival to departure and trace the path your hands take to gather what you need. This mental map helps you allocate space for heavy items to stay low and centered, for frequently used tools to rise to waist level, and for smaller, high-turnover components to be within reach without cluttering the main work zone. You begin to understand how much of your storage is wasted on items you rarely touch, and you start to reimagine what a compact, efficient layout would look like if every inch of the interior served a purpose.

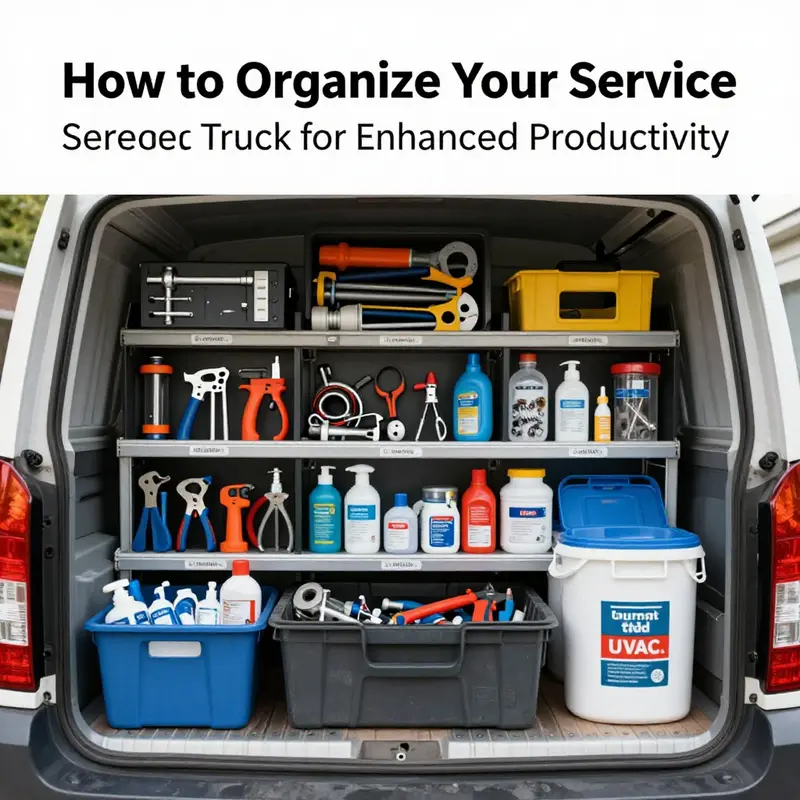

The moment of greatest clarity comes when you identify unused space. Look for gaps behind doors, under seats, and along the ceiling of the cargo area, where you can install modular storage without sacrificing mobility. The idea is to convert every nook into a functional zone. Consider overhead racks for bulky items like ladders, hoses, or spare shelves. Vertical space becomes a strategic asset when you stop treating it as waste and start treating it as a reservoir of organized potential. This is where the notion of zones takes hold. Each zone is a clearly defined area inside the truck for a category of tools or for a stage of the workflow—one for electrical components, one for plumbing fittings, one for test instruments, and another for consumables such as tapes, fasteners, and sealants. The zones keep your work rhythm intact; they reduce the time spent searching and prevent cross-contamination of different tool groups. A well-planned layout also has to account for balance and driving dynamics. Heavier items belong lower and closer to the vehicle’s center. You want a low center of gravity to protect the ride quality and minimize shifting during transport, especially when you hit uneven terrain on a site.

Implementation follows evaluation. After you’ve emptied, assessed, and identified new space, you implement modular storage that can be reconfigured as your needs evolve. Bins and labeled containers should be sized to hold the typical quantity of a given category and should be easy to remove for inspections or restocking. Drawers can house frequently used tools in a predictable order, so your hand knows where to go without you needing to search. Pegboards add a quick visual cue of what’s present and what’s missing, making it easier to see at a glance when something has wandered or gone missing. When arranging, aim for a simple, repeatable pattern. If you choose a pattern of zones, keep that pattern consistent so your muscle memory kicks in with every stop. You’ll be surprised how quickly a repeatable, modular approach reduces the cognitive load you carry on a busy day.

The strategy then turns toward everyday use and maintenance. A daily routine is your insurance against creeping disorder. At the end of each shift, you return everything to its designated spot and wipe the surfaces that have become greasy or dusty. A short checklists, visible on a small whiteboard or a laminated card, can remind you to inventory your essential items before you lock up: are spare fuses in their bin, are sealants capped and labeled, is the first-aid kit intact, are the insulated gloves dry and reachable, are the flashlight batteries fresh? This habit is not a luxury; it’s a safeguard that reduces the risk of missing equipment on a job and helps you keep your truck mission-ready after every service call. Over time, periodic audits become part of your routine: a quick, quarterly pass to rotate stock, refresh worn-out items, and revalidate zone assignments as your work evolves. If you manage a fleet or work within a private system, you’ll find that a disciplined interior organization also supports broader maintenance schedules and lifecycle planning. See how this aligns with private fleets trends in trucking maintenance for broader context and practical insights into how clean interiors support maintenance discipline. Private fleets trends in trucking maintenance

A crucial benefit of starting with a complete reset is the ability to tailor your layout to your actual workflow rather than a theoretical design. Your most-used tools should be the easiest to reach and should sit at waist height or slightly below, forming the core of your task flow. Heavier, bulkier items should stay lower to keep the center of gravity stable while driving and to prevent unbalanced loads when you swing into a tight site. The arrangement should allow you to move freely within the truck as you work on a project, without moving items out of the way to access the next tool. The goal is not just speed but also safety: fewer misplacements mean fewer trips to the back to fetch a tool, and a stable interior reduces the risk of items shifting or tipping during transit.

As you move beyond the initial reset, you’ll discover that organization is more than just a place for things; it’s a scalable system that can adapt to changing demands. If you add more electrical kits, or if a new line of fittings becomes common on your calls, the modular approach makes it easier to rezone and re-equip without tearing the whole truck apart again. The reset becomes less of a one-off project and more of a foundational mindset—an ongoing discipline rather than a single act. When you maintain this mindset, you protect your time on the road and preserve the integrity of your tools by keeping them clean, labeled, and in the correct context. The rhythm of resetting, assessing, and reconfiguring becomes the natural cadence of your operations, the silent backbone of reliable, repeatable service.

In practice, the complete reset also interacts with broader organizational goals. A well-ordered interior reduces search time, which translates into faster job starts and shorter dwell times between calls. It also reduces wear and tear on tools, since properly stored items experience less banging and jostling during transit. And it fosters a calmer, more confident mood when you step into a site—knowing you have everything you need within reach can dramatically cut cognitive load and anxiety on the job. For teams that think about maintenance as a shared responsibility, keeping the truck organized is a tangible commitment that supports the entire maintenance ecosystem, from inventory management to technician readiness. The reset, therefore, is not a cosmetic improvement; it is a practical investment in reliability, safety, and efficiency that pays dividends across every job you take on.

To keep this momentum, a simple but powerful practice is to create zones, label what belongs in each zone, and keep a visible, small checklist for restocking. The zones become living modules; they can be swapped, added to, or reduced as your work changes, without requiring a full rebuild. This approach makes it easier to train new team members on the standard operating procedure for the truck, since the zones map directly to their tasks and the sequence of actions they perform when departing for a job. The overall effect is a vehicle interior that feels designed rather than improvised, a working cockpit that supports you rather than fights you. As you continue through your days on the road, you’ll notice that the initial work of clearing and organizing reframes how you think about each tool, each container, and each space you occupy in the vehicle. It’s a shift from accumulation to curation, from keeping safe to keeping ready, and from reacting to planning.

For operators who want broader context on how interior organization dovetails with fleet maintenance and operations, the practical insights from industry resources offer a useful complement to your hands-on reset. This broader perspective helps you see the interior as part of a larger system, where the maintenance cadence, the inventory lifecycle, and the vehicle’s utilization all feed back into how you arrange, restock, and refresh your truck’s interior. The reset then becomes the opening act of a longer performance—the daily workflow that keeps you moving efficiently from one call to the next. As you continue to refine your system, you’ll find that small adjustments—relabeling a bin, swapping a shelf for a drawer, or relocating a frequently used kit to a more prominent spot—can yield outsized gains in speed and safety. This is the essence of organizing: it’s not a one-time event but a durable, adaptive practice that respects the realities of field work and the need to stay ahead of the curve in a dynamic service environment.

To close this chapter, the reset is your launchpad. It is where you leave behind clutter, guesswork, and inertia, and step into a deliberate design space where space, weight, accessibility, and workflow all align. It’s a practical, repeatable process that improves your daily efficiency and reinforces the safety of every site you visit. By embracing the reset, you begin a journey toward a service truck that truly supports your work—proving that the best tool you own is not just the factor of your toolbox but the thoughtful arrangement of your entire mobile workspace. For those who want to explore how interior organization plays into broader maintenance strategies across fleets, and to access practical, field-tested guidance, consider the linked external resource that outlines the principles of service truck organization and its impact on operations. service-truck-organizational-tips guide

From Clutter to Command Center: Mastering Tool Categorization for Your Service Truck

Moving from a blank interior to a working mobile workshop starts with a clear map of how and why items are used. Categorization is that map. In a roadside or shop lot, seconds matter, and the difference between grabbing the right tool on the first try and fumbling through a jumble often comes down to where things live and what they are used for. This chapter builds that map by teaching you to group tools by function and by usage frequency, to design storage that withstands vibration and weather, and to weave safety, technology, and daily discipline into a system that travels with you rather than dragging you down. The goal is a living workspace that stays intuitive under pressure.

Begin with purpose-driven grouping. Organize tools by their primary job and how often you reach for them: tire repair, electrical diagnostics, mechanical repairs. Within each group, place the essentials close at hand: the wrenches, pliers, a tire gauge, a compact inflator, and a small routine toolkit; for electrical work, insulated screwdrivers, a reliable tester, wire strippers, and common crimping tools; for mechanical repair, a robust socket set, fasteners, a hammer, and a handful of replacement seals. The idea is simple: give every item a home that matches how you actually work, so your truck behaves like a portable workshop rather than a jumble on wheels.

Placement and safety reinforce the system. Put the most-used items within easy reach at waist level, and store heavier items on lower shelves secured against movement. Use modular boxes, labeled bins, and a pegboard that shows your daily routine at a glance. Create a dedicated safety corner with a first-aid kit, a fire extinguisher, reflective gear, and emergency lighting in a high-visibility zone near the cab. When safety and tools share a logical home, response times improve and stress drops.

Technology can extend the system beyond physical shelves. Simple digital checklists, barcode tracking, and RFID tagging can help you know at a glance what you have, what’s in use, and what needs replacement. The aim is not to replace hands with screens, but to speed up access to the right part by eliminating unnecessary trips to the shop. Finally, make end-of-day routines a habit: return everything home, wipe down tools, check for wear, and perform quick audits to ensure nothing is missing. A disciplined routine keeps the system honest and your vehicle ready for the next call.

From Clutter to Command: Building a Service Truck That Runs Like a Workshop on Wheels

A service truck should feel like a compact workshop, not a catchall for junk. The path from chaos to clarity begins with a complete reset, a deliberate clearing of the deck so you can see every inch of space and decide what truly belongs there. Empty the cab, the compartment, and the bed if you carry gear in the rear. As you lay items out on the ground, ask three questions about each tool or part: Do I use this every day? Could I replace it with something more versatile? Can I store it elsewhere without compromising readiness? This reset is not a purge for its own sake but a strategic inventory that reveals real needs versus routine “just in case” clutter. When you fill the space again, you are building a system, not merely piling up gear. The goal is a truck that supports your work, not a truck that works you into a knot of fatigue.

With a clean slate, you can start categorizing your tools and supplies in a way that mirrors your workflow. Group similar items together—plumbing tools in one zone, electrical components in another, HVAC supplies in a separate area, hand tools in their own drawer sets. This categorization creates natural homes for what you own and reduces the time spent searching. When you pull a tool, you should understand immediately where it lives, how it is stored, and how it returns. The cognitive load of hunting for equipment disappears, replaced by a simple, confident rhythm. This is the essence of efficiency on the road: when everything has a designated home, you never waste precious minutes rummaging through a mixed pile.

Quality storage is the backbone of that rhythm. The investment in modular toolboxes, drawers, pegboards, bins, and clearly labeled containers pays off through steady, repeatable access. Toolboxes with configurable trays let you split big tools from small connectors, while labeled bins keep fasteners, seals, and fittings organized by size or type. Pegboards, mounted at waist height, hold frequently used items in plain sight, with hooks and magnetic strips adding a flexible layer for quick grabs. Consider overhead racks for ladders and longer items that would otherwise crowd the floor. The trick is to maximize vertical space and to position frequently used items within arm’s reach. Such a layout reduces bending, crouching, or reaching across a cluttered bench, which translates directly into safer, quicker jobsite transitions.

A thoughtful layout then anchors to a simple rule: place items by frequency, with heavier tools stored lower and easier to load. The heaviest items should sit where they won’t shift during transit, ideally near the floor or into lower cabinets that stay stable as the truck moves. Lighter, high-spirited items—small fittings, cords, and fasteners—can be positioned at mid-level or in wall-mounted racks that keep them visible and accessible. A clean, intuitive hierarchy minimizes the need to bend or twist to retrieve a needed part, and it makes reorganization easy when you add or change equipment. Every configuration should invite one glance and one grab; no tool should demand a chain of custody to reach.

A well-planned system also extends to the daily ritual that keeps it alive. At the end of each shift, return items to their designated homes. It sounds simple, yet the cumulative effect is profound: a clean truck every morning eliminates the friction of re-discovering missing parts and reduces the risk of carrying duplicate purchases. Periodic audits keep the system honest, too. A quick quarterly check confirms that nothing is missing, damaged, or outgrown, and that the layout still matches your evolving workload. As you refine, you’ll notice that the simplest adjustments—shifting a pegboard hook, resizing a drawer divider, or relocating a heavy tool to a lower shelf—can compound into noticeable gains in speed and precision.

Beyond physical organization, the chapter of a service truck’s efficiency is written in the language of movement and data. Digital integration, when used thoughtfully, amplifies what physical order alone cannot achieve. A cloud-based telematics platform can deliver real-time vehicle data, maintenance alerts, and fleet management insights that help you keep the truck in peak condition and schedule service before issues become disruptions. This digital backbone doesn’t replace the tangible organization; it complements it. The truck becomes a coordinated system where your routes and tools are synchronized with the vehicle’s health, enabling you to anticipate service windows, avoid roadside delays, and minimize downtime. This is not about software for its own sake but about a predictable, proactive workflow that makes every job feel less like a scramble and more like a well-rehearsed routine.

The beauty of combining sturdy physical storage with digital awareness is that you can tailor your setup to the work you actually do. If you frequently carry small parts, design a drawer stack with labeled trays that distinguish by size and type so you can see, sort, and grab at a glance. If your work requires a mix of bulky items, allocate a dedicated subspace for long items and provide quick-release straps so you can secure them firmly without unloading the rest of the truck. When parts or tools are easy to find and secure, your hands are free to focus on the job rather than the search. The same logic applies to power tools and diagnostic devices: keep the most-used cordless tools and essential meters within a short, safe reach, and store the rest in a stable, labeled zone where they won’t rattle loose on rough roads.

As the organization deepens, consider how your system interacts with broader industry trends and the day-to-day realities of fleet operations. Even as you optimize the cab and the storage, you can benefit from insights into maintenance schedules and equipment utilization that come from broader fleet data. For example, private fleets trends in trucking maintenance discuss how maintenance cycles and tool usage patterns influence inventory decisions in real-world operations. The link between on-site efficiency and comprehensive maintenance strategy becomes clearer when you see maintenance alerts not as interruptions but as signals to refactor your layout or stock levels to prevent downtime. Integrating upkeep data with your on-truck storage can help you forecast parts needs, schedule restocks, and avoid carrying excessive quantities of rarely used items. In practice, you might notice that a particular fastener kit tends to vanish after a string of heavy jobs; that awareness guides you to keep a tighter, more visible display of those items, or to place them in the most secure drawers so they stay accessible and accounted for.

The narrative of organization, then, is both tactile and cognitive. On the bench, you feel the weight of each tool and know its exact place; in your head, you carry a mental map of workflows and replenishment needs. When a job starts, you already envision your path through the truck: the route to the most frequently used tools, the quick detour for a spare part if needed, the secure stowage for items that travel with you for long distances. This mental model is reinforced by the physical cues you create—labels, color-coded trays, and consistent spatial logic across every vehicle in your fleet. It is this harmony between space and sequence that turns a service truck into a reliable partner, a mobile workshop that respects both your time and your safety.

Finally, a note on practical guidance and continual improvement. The exact configuration will mirror your unique work ecology—your typical jobs, the climate you operate in, and how you move between sites. You do not need to imitate anyone else’s system; you need a system that works for you, that scales as your workload changes, and that remains intuitive enough to preserve speed under pressure. The objective is not to cram every possible tool into the truck but to curate the right toolkit for the most common tasks, with the flexibility to adapt when unusual jobs appear. In time, the truck will reveal its own adaptive logic—the modular drawers will invite rearrangement, the shelves will tolerate new formats, and the digital layer will predict needs with increasing accuracy. That is the essence of being prepared: a workspace that travels with you, organized not just for today, but for the next job and the one after that.

For readers seeking a broader, step-by-step reference that complements these ideas, the following resource offers practical setup and best practices: the Spruce guide on organizing your service truck. It provides actionable techniques that align with the principles described here and can serve as a useful companion as you tailor a system for your own work. You can explore further at https://www.thespruce.com/organize-your-service-truck-4139852. In parallel, consider visiting industry-forward discussions such as private fleets trends in trucking maintenance to gauge how your organization fits into evolving maintenance patterns and parts strategies. A concise, ongoing awareness of these dynamics can help you refine inventory choices, anticipate demand, and maintain a lean, efficient service vehicle that continues to perform under changing conditions.

Mapping the Fleet: Implementing a Systematic, Space-Saving Layout for Your Service Truck

A service truck is more than a toolbox on wheels; it is a mobile workspace where every inch of space can shave minutes off a call and every misplaced tool can cost a moment you’ll never get back. The most durable gains in efficiency come from a deliberate, repeatable process rather than clever gadgets alone. The starting point is a complete reset: pull everything out, clear the floor, and expose what actually earns its keep on the job. When the truck is empty, you can see the true footprint of your workday—the hoses, the fittings, the fasteners, the test equipment—that must come along and the items that can stay behind. This is more than tidying up; it is a strategic rethinking of what you carry, how you access it, and how you move through space without tripping over clutter or juggling mismatched containers. The reset also forces you to confront the question that every technician eventually asks: do I really need this “just in case” item? By identifying items that are rarely used or only marginally effective, you free up real estate for tools that transform everyday tasks into predictable, repeatable actions. The immediate reward is obvious—the floor is clear, the shelves breathe, and the sight lines improve. But the deeper payoff lies in the clarity that comes from seeing a well-designed system take shape, a system that you can maintain because you built it to be simple and durable from the start.

Once the truck is empty, the next step is to categorize what you own, not by the way you bought it or where you dropped it last time, but by function and frequency of use. Group related tools and supplies into functional families: plumbing, electrical, HVAC, and general hand tools form the backbone of most service stops. Within each family, separate essentials from nice-to-haves and place the former in the most accessible locations. This categorization mirrors the way a site visit unfolds: you begin with the most common tasks, you move to more specialized work, and you finish with closing chores like testing or cleanup. The goal is to create a home for every item and to guarantee that items within a home are consistently organized the same way, day after day. When multiple technicians share a vehicle, labeling becomes essential. Clear labels on containers, drawers, and bins reduce errors, shorten searches, and promote a culture of accountability. If you work with a team, a standardized labeling system helps new hires climb the learning curve quickly and minimizes the chaos that can arise from turnover. If you’re solo, labeling remains your on-ramp to speed and accuracy, a personal map you can rely on every morning.

The heart of a systematic layout is a thoughtful choice of storage solutions that can adapt to changing needs. Invest in a mix of durable toolboxes, wall-mounted racks, and drawer systems that can be reconfigured as your truck evolves. Overhead racks, when installed correctly, unlock precious vertical space for long items like ladders, levels, reels, and rolled hoses. Drawer systems offer defined, shallow wells for small fasteners, seals, and fittings, while wall-mounted pegboards keep frequently used items within arm’s reach and visible at a glance. The design philosophy is simple: keep the items you reach for the most at waist level and provide sturdy, stable storage for heavier equipment lower down to maintain balance while the vehicle is in motion. This balance isn’t just about comfort; it’s a safety imperative that reduces shifting payload during transport and helps protect both tools and people from unexpected movement. Consider how your daily routine shapes the layout. If you routinely perform long, methodical installs, your most-used tools should sit along a continuous, reachable line on the driver’s side or center area, so your hands don’t need to travel far between steps. If your work includes frequent retrieval of smaller parts, a shallow, clearly labeled drawer system at mid-height becomes a quick, repeated ritual rather than a scavenger hunt. The intent is not just to store; it is to create a workflow inside the vehicle that mirrors the workflow at the job site, so the transition from truck to site is seamless and almost invisible.

A good layout also accounts for how you move around the cab. It should minimize bending, reaching, and twisting, while still preserving space for a productive standing zone near the work surface. Heavier items—air compressors, spare batteries, or compact generators—should be placed lower and toward the strongest part of the frame to keep the vehicle stable and easy to handle when parked. The design should also reflect practical considerations like weather, access to power, and the need for quick transfers between the truck and the site. A pegboard or slat wall can serve as a dynamic spine for reorganizing, offering the flexibility to relocate hooks, bins, and small parts without extensive remodeling. The labels you apply to every container, drawer, and shelf reinforce the system. They are not decorative; they are your immediate assurance that what you put in a space is exactly what you intended, and that others who use the truck will find it in the same place every time. The success of the layout hinges on discipline: every item has a designated home, every home is obvious, and every user understands where to return items after a job. This discipline reduces the chance of missing tools and the downtime caused by digging through opaque stacks of equipment.

To translate this approach into a working reality, it helps to anchor your plan in a few guiding practices. First, let frequency drive placement. Items you grab repeatedly should live within the quickest reach, while rarely used components can live higher in a lofted area or in a compartment that is still accessible but not part of the core routine. Second, build a predictable path: a starting point near the door with the most-used items, followed by zones for secondary tools and specialized gear. This creates a spatial rhythm that your body learns, which in turn sharpens your reaction time and reduces cognitive load when you are under pressure. Third, harness the power of labeling. Consistent typography, color-coded bins, and clear, durable tags cut through confusion in the middle of a busy workday and make it easier for a teammate to fill in where you left off. Fourth, preserve the balance and stability of the load. Position heavy gear low and close to the vehicle’s center of gravity, distribute weight evenly across the axles, and secure items with tie-downs or latching systems that withstand vibration and sudden stops. Without this attention to weight distribution, you may save a few seconds in tool access but pay with a wobbling ride, increased wear on suspension, or a higher risk of loose items becoming projectiles in transit.

Of course, the physical layout is only part of the story. A systematic approach requires a routine that keeps the space tidy and the inventory accurate. End-of-day rituals matter as much as the initial setup. A few minutes spent returning every tool to its designated home after a job may seem like a small investment, but it compounds into substantial gains over weeks and months. In practice, this means performing a quick audit before you close the door: check that all essential items are accounted for, confirm that labels remain legible, and note anything that needs replenishment. For longer-term health of the system, adopt a light inventory routine that uses a simple checklist or a digital log to track stock levels, tool condition, and replacements. The idea is not to overcomplicate the process but to create a repeatable pattern that makes shortages and misplacements rare events. With a reliable inventory discipline, you can preempt shortages, plan service windows more accurately, and reduce the stress that comes from digging through a tangled bin when a client is waiting. This disciplined redundancy—knowing you can locate what you need and knowing that you are prepared for what you don’t—translates into more confident, faster service delivery, and it reinforces the professional image you present to customers.

The beauty of a well-executed systematic layout is that it grows with you. As your fleet evolves, as tools change, or as you take on more complex jobs, you can reassign zones, reconfigure drawers, and swap in new storage accessories without starting from scratch. The essential rule is to design for adaptability rather than perfection. A space that can be rebalanced with a few simple moves is far more valuable than a fixed installation that cannot accommodate growth or changing demands. A final consideration is the broader perspective—the integration of your truck system with the rest of your operations. If you are exploring new market realities or shifts in the industry, there are practical lessons to be learned from how fleets adapt to changes such as new technologies, supplier landscapes, or regulatory environments. For a broader read on how evolving equipment and market conditions influence fleet design, you might explore topics like the Harbinger electric trucks Canada market-entry, which discusses how technology and policy can reshape vehicle choices and operational planning. This broader lens helps you see your truck layout not as a static shell but as a dynamic platform that supports current work and future growth. Harbinger electric trucks Canada market-entry.

In the end, a well-organized service truck is a quiet advocate for productivity. It reduces the time spent searching, lowers the risk of tool loss, and minimizes the physical strain of shifting and reaching in tight spaces. It also safeguards your safety by eliminating clutter-induced hazards and by providing a stable, predictable work environment, even in the tight confines of a mobile workspace. The Esri guidance on service-truck organization reinforces this perspective by outlining practical layout strategies and tool-management practices that align with a workflow-driven approach. Implementing a systematic layout is not a one-time project; it is a continuous practice of evaluating space, refining placement, and maintaining discipline. When you treat your truck as a living part of your operation—one that you can tune, adjust, and improve—you enable yourself to deliver a higher level of service with less stress, fewer delays, and greater reliability. As you move through this process, keep the core idea in view: your vehicle should support your work, not complicate it. A clear floor, defined tool homes, and a layout that follows your daily routine are the underpinnings of a service experience that is professional from first contact to final wrap-up, a seamless integration of mobility and craft that keeps you ready for the next job.

External resource: Esri’s Service Truck Organization guidance offers an external, in-depth look at layout and tool-management practices that can complement this chapter’s approach. https://www.esri.com/arcgis-blog/products/arcgis-pro/operations/service-truck-organization/

Maintaining Momentum on the Road: A Holistic, Regular Rhythm for Organizing Your Service Truck

A service truck is more than a moving toolbox; it is a compact workflow hub that shapes every day’s speed, accuracy, and stress level. The moment a technician climbs aboard is the moment the vehicle’s interior either supports a smooth, confident job or becomes a dragging weight that slows everything down. The principle of maintaining order regularly rests on a simple premise: empty the truck, rethink what actually belongs there, and repeat the process as a daily habit. A complete reset does not merely purge clutter. It creates a fresh mental map of the space, exposing wasted gaps and obvious bottlenecks the moment you step inside. When the doors close behind you at the end of a shift, the map should already be set for the next day. The goal is not perfection in the moment but consistency over time, so that each morning begins with clarity and a clear plan, not a scavenger hunt for the right tool.

The reset begins with an honest, almost clinical assessment. Remove every item and lay it out in a staging area. You will quickly see what you truly rely on versus what has crept into your inventory “just in case.” The easiest way to start is to separate tasks by type rather than by tool size. Plumbing and gas-fitting components, electrical components, HVAC supplies, and hand tools all deserve their own designated neighborhoods. This is not about labeling for the sake of organization; it is about creating mental anchors. When work pieces move from one job to another, the anchors guide you back to where they belong, and that reduces the cognitive load required to locate them on the fly.

Once the space is cleared, the real design work begins. The arrangement should follow how you work, not how you carry items. Think of your truck’s interior as an extension of your workflow: the first reach should be to the most frequently used tools, ideally at waist level, where you can access them without bending or twisting excessively. Heavier items—like large wrenches, heavy power cords, or bulky manifolds—should live lower. This keeps center of gravity stable while you drive and makes loading and unloading safer. It also reduces fatigue because you are not repeatedly lifting items to awkward heights. If you have space for overhead storage, reserve that for longer items you use only occasionally, like ladders or portable generators. The aim is to maximize vertical space without compromising access to the items you use daily.

With the major space and weight considerations in place, the next layer of order comes from how you categorize and store. The moment you open a drawer or a bin, you want to picture the exact item you expect to find there. Clear labeling is the quiet engine behind this mental map. It is not merely about knowing that something is in a bin but knowing exactly where in the bin it lives. Labels become instructions for memory and behavior. They reduce the time spent searching and the probability of misplacement, which then translates into fewer lost minutes on a job. In tandem with labels, consider adding small, purpose-made trays for different tool families. A tray for screwdrivers, one for pliers and cutters, another for fasteners, and yet another for fittings—all designed to keep tools from shifting during travel and to prevent items from mixing into a single, hard-to-navigate jumble.

Modularity is the friend of a service truck that must adapt to varying jobs. A modular storage system can be adjusted as the work changes—whether you switch to a different service line or you bring in specialty components for a particular site. Modular, configurable drawers and removable dividers let you tailor a space for today’s needs and quickly swap it for tomorrow’s. The idea is to build a flexible skeleton you can lean on when the job shifts, rather than a rigid filing cabinet that confines you to a single past routine. In practice, this means investing in durable, customizable storage that can withstand the bumps and dust of daily field use while still allowing you to reconfigure quickly after every job. And because space is always finite, the vertical dimension is as valuable as the horizontal: make every inch work by stacking, shelving, and securing items so nothing rattles loose or leans into a doorway during transport.

The workflow-driven layout must align with how you move around a client site. A clear, uninterrupted path from the cab to the work zone is essential, and this flow should be mirrored inside the truck as well. You want the most commonly used tools within easy reach, with room to maneuver around the vehicle’s interior as you stretch, bend, or turn. A well-thought-out layout is a quiet partner: it doesn’t demand attention, but it pays dividends in accuracy and speed. When everything has a home, the end of the day becomes a completion of a cycle rather than a problem of a pile. You can finish a job and step out with a sense of completion rather than a nagging reminder that you left something behind.

Of course, order is not a one-and-done achievement. It is a habit, reinforced by a disciplined end-of-day routine. The daily ritual should be simple and reliable: return every item to its designated spot, visually confirm that the label remains legible, and reset the space for tomorrow’s tasks. A quick, 60-second inventory at the end of each shift can catch items that may have shifted during transit or during the last minutes of a job when speed is prioritized over placement. Regular audits—brief, scheduled checks of each bin, drawer, and tray—keep the system honest and aligned with your current work. If a tool doesn’t fit your daily routine anymore, replace it with something that does. Maintenance is not about keeping things pristine; it is about preserving function and reducing friction.

What keeps the system alive is not only how well you set it up but how you stay tuned to broader industry rhythms. The broader trucking and service ecosystem continuously evolves, and the best operators adapt their internal organization to these changes. Reading industry trends helps you anticipate shifts in demand, common service types, or seasonal ebbs and flows that alter what you need on board. For instance, shifts in regional freight patterns or infrastructure investments may change the mix of parts and tools you stock regularly. Keeping pace with trends helps you decide when to tighten a specific category, expand another, or reallocate space for different kinds of materials. In this sense, the truck becomes not only a tool carrier but a real-time signal of how your business evolves, and maintaining order becomes a dynamic practice rather than a static rule. For those looking to align their internal organization with current industry movements, a practical touchstone is the ongoing examination of market indicators and labor dynamics—a lens captured by economic-trucking-trends.

Beyond the interior, your approach to route planning and fleet health also feeds back into the truck’s organization. When you know how you will move between sites, you can stage the truck for the day with a more precise balance of tools and spare parts. Route efficiency reduces unnecessary driving time, which in turn lowers the risk of items shifting during a long ride and helps you keep heavier items properly secured and accessible. It also supports safer loading practices, because you plan to minimize unnecessary movements that could destabilize the vehicle’s load. The deeper implication is that your organization is not merely about keeping things tidy but about sustaining a reliable, predictable workflow that reduces fatigue and error across the entire operation. The most durable systems are those that anticipate rather than react, and every improvement in routing capability ripples back to how you place tools, how you label them, and how quickly you can reach what you need when you arrive at a job.

Regulatory awareness remains a quiet but essential thread in this fabric. Transportation safety regulations, especially during peak demand periods or seasonal spikes, can alter how you load, secure, and transport equipment. Knowing the guidelines helps you preempt penalties and delays, and it also informs how you design your interior fixtures. If a rule changes, your modular storage system can adjust to meet the new requirements without a complete overhaul. This continuity matters: a truck that can adapt to regulatory shifts without sacrificing efficiency is a valuable asset. And the same disciplined routine—reset, assess, reorganize, label, and maintain—becomes a shield against drifting out of compliance as the business environment shifts. For readers seeking a broader, external perspective on route optimization and fleet deployment, consult practical resources on networked planning and path optimization, which provide structured methods for reducing travel time and fuel use in real-world conditions.

The overarching message is straightforward: order is not a single act but a continuous discipline that travels with you from the garage to the job site and back again. A complete reset unlocks a clearer space, but it is the daily behavior—the return of items to their homes, the maintenance of labels, and the willingness to adjust layouts as needs change—that preserves the system. The inside of a service truck should feel like a well-tuned instrument: the parts are reachable, the spaces are purposeful, and the cues for action are obvious, not learned through trial and error each morning. When you adopt this rhythm, your days become less about searching and more about doing. Consistent upkeep translates into faster response times, fewer misplacements, and a calmer mindset on the road. And as your truck supports a steadier workflow, it also supports your broader business goals: higher on-site efficiency, improved safety, and more predictable service delivery.

External resource: For a deeper, technical exploration of how route optimization can complement a well-organized vehicle fleet and improve delivery sequencing, refer to established routing theory and practice here: ArcGIS Vehicle Routing Problem.

Final thoughts

In summary, effective organization of your service truck is essential for improving productivity and reducing stress on the job. By starting with a complete reset, categorizing your tools, using robust storage solutions, implementing a systematic layout, and maintaining regular order, businesses can ensure that their operational efficiency skyrockets. This comprehensive guide offers actionable insights tailored for manufacturing, retail, construction, and more, equipping you to streamline processes and enhance the overall workflow.