Understanding the offerings of Wilson’s Truck Lines provides crucial insights for manufacturing, retail, construction, and small businesses alike. Often misinterpreted as a ministry service, Wilson’s Truck Lines is a logistics and transportation powerhouse dedicated to providing top-tier logistic solutions. This article elucidates the operational excellence achieved through innovative technology, the unwavering commitment to customer satisfaction encapsulated in the motto ‘Never Say No’, and the digital transformation addressing significant operational challenges. Each chapter delves into these dimensions, enhancing the collective understanding of their impact on modern logistics.

Debunking the Myth of Wilson Trucking Ministry Service: Unraveling a Misconception About Wilson’s Truck Lines

When readers first encounter the phrase Wilson Trucking Ministry Service, a vivid image often forms in the mind. Some imagine a faith oriented outreach, a community program, or a government backed initiative with a mission that blends logistics with public service. In the world of trucking and freight, such a label would be unusual and, as we will see, inaccurate. The business landscape around Wilson’s Truck Lines in Ontario is rooted in private enterprise, not a ministry or a religious service, and the boundaries between myth and reality here matter. To understand why this misconception circulates, it helps to start with the actual scope and character of Wilson’s Truck Lines as it operates today. The company exists to provide efficient, innovative logistics solutions for packaged goods, serving a broad roster of commercial customers who rely on timely deliveries and dependable service. Its size and footprint in Ontario illustrate both the complexity and the sophistication of modern freight operations in a region where supply chains are constantly in motion and where speed, accuracy, and reliability can define a carrier’s reputation.

From the outside, the story of Wilson’s Truck Lines reads like a textbook case of a regional carrier that grew with the economy. It has built a network of yards, a sizable fleet, and several distribution centers that collectively form an integrated system for moving goods from point A to point B with precision. The company has expanded beyond a single facility to manage operations across multiple yards, with hundreds of trailers designed to handle a mix of dry and temperature controlled shipments. The scale itself is a testament to the demand for robust logistics in a fiercely competitive sector where retailers and manufacturers alike push for shorter lead times and tighter inventory control. Yet scale alone does not explain how a private carrier earns a reputation for reliability. What matters is the way the operation connects people, processes, and data to create a flow that customers can trust even in the face of disruption.

A central thread in this story is the company motto, a concise statement that has become a touchstone for how it approaches customers and problems. Never Say No embodies an ethos of proactive problem solving and commitment to service. It signals a willingness to explore alternative routes, adjust schedules, or reallocate resources to meet a customer need. In an industry where delays and miscommunications can ripple through a supply chain, a philosophy that leans toward flexibility and accountability can be the difference between a missed delivery and a satisfied customer. That mindset harmonizes with the broader goal of premium service: not simply moving goods from one place to another, but delivering predictable, transparent, and responsive partnership. The metaphor of a ministry would imply a non profit or public service structure. In contrast, what Wilson’s Truck Lines demonstrates is a privately funded, profit driven enterprise that integrates customer care into the core of its operating model. The distinction matters because it influences expectations, governance, and how the business communicates about its capabilities.

Beyond the rhetoric, the operational reality of Wilson’s Truck Lines is anchored in a disciplined approach to capacity and control. Ontario is a dense, dynamic logistics landscape with a mix of urban hubs and regional routes that require careful choreography. The company’s footprint—spanning several yards and four distribution centers—reflects a deliberate strategy to balance proximity to major markets with the need to move freight efficiently across the network. This arrangement is not a ministry constrained by public sector mandates; it is a private enterprise that must optimize every mile, every hour, and every load to remain competitive. The scale brings complexity, and complexity demands systems that can keep pace with real time demands. It is here that the benefits of digital transformation come into sharp relief. A manual approach would struggle to keep up with the sheer volume of daily transactions, the variety of shipments, and the need for rapid decision making. The transition from paper to digital workflows has been a turning point for the company, enabling much tighter coordination across yards, better visibility for customers, and a level of operational agility that was previously unattainable.

One of the most telling illustrations of this transformation is the replacement of a long standing, manual yard check routine with a digital process. In the old model, staff carried clipboards, recorded trailer locations, contents, weights, and refrigerated temperatures, then tried to reconcile those notes with the company’s Transportation Management System (TMS). The process was not only time consuming—taking four to five hours per day—but also prone to human error and data silos. A four to five hour daily ritual for yard checks is not just a cost in labor; it is a latent risk for misloads, misplacements, and miscommunications that can cascade into delays and cost overruns. The shift to a digital system, integrated with the enterprise data architecture, is more than a productivity gain. It is a fundamental upgrade to situational awareness. Real time visibility into trailer locations, contents, and environmental data is no longer a separate activity; it becomes a seamless thread that informs dispatch decisions, compliance reporting, and exception handling. The yard, once a collection of physical checkpoints, becomes a live data surface that supports proactive management rather than reactive firefighting.

In describing this evolution, it is important to avoid naming particular vendors or product brands. The point is not to advertise a specific vendor but to acknowledge a universal truth about modern logistics: data integration and real time analytics change what is possible on the ground. The company deployed a cloud based platform that harmonized operations across yards and centers, anchored by a centralized data repository capable of scaling with growing volumes. That foundation enabled not only efficiency gains but also a dramatic improvement in accuracy and reliability. When a shipment arrives, the system can automatically confirm its status, alert if a temperature excursion occurs, and present operators with a single source of truth for every load. For customers, this translates into higher service levels, more consistent delivery windows, and greater confidence that their goods are handled with care. For the internal teams, it means fewer duplicated data entry tasks, faster reconciliation, and clearer accountability across roles. The net effect is a more resilient operation that can absorb shocks—seasonal spikes, equipment shortages, or weather related disruptions—without collapsing into chaos.

The broader industry context helps illuminate why this transformation is both timely and essential. The trucking sector in Ontario and across North America is navigating a confluence of pressures: tight capacity, rising operating costs, shifting regulatory expectations, and increasingly sophisticated customer demands for transparency. Economic trends are shaping who can invest in technology, which fleets can scale, and how quickly a carrier can deliver on complex service requirements. The momentum toward digitalization is not optional; it is an operating necessity for carriers that want to compete on reliability and cost effectiveness. For readers who want to situate Wilson’s experience within the wider industry arc, a close reading of the latest discussion of economic trends affecting trucking provides useful context. The topic of key economic trends impacting the trucking industry, for example, offers a framework for understanding how investment in digital tools translates into tangible performance improvements and enduring competitive advantage. You can explore this topic further here key economic trends impacting the trucking industry, which ties macro level shifts to the micro level realities of yard operations, route planning, and customer service.

The misperception that this private logistics enterprise operates as a ministry is not merely a curiosity; it reveals how easily branding and terminology can blur the lines between different kinds of organizations. A ministry implies a public, often non profit mission, with oversight that is distinct from private sector governance. A private carrier, guided by a service ethos and a sustainable business model, relies on customer relationships, contract terms, and performance metrics that define its success. Clarity here matters because it affects how customers perceive value, what they expect from a partnership, and how they measure a carrier’s performance. When stakeholders encounter a label that evokes a public service or a religious mission, they may unconsciously conflate public accountability with private accountability. The reality, however, is that while Wilson’s Truck Lines commits to premium customer service and operational excellence, the enterprise remains a private entity with a clear commercial purpose. In the landscape of logistics, such distinctions matter not as a matter of trivia but as a guide to understanding how services are framed, delivered, and evaluated.

This distinction also has practical implications for how information about the company is communicated, both to current customers and to the broader audience of readers seeking to understand the industry. Corporate communication, especially in an asset heavy and regionally scoped business, benefits from precision in language. The Never Say No ethos, for instance, is not a slogan borrowed from a ministry but a declaration about the company’s willingness to address challenges and explore alternatives. It signals a commitment to customer success that aligns with the operational realities described above: a network built on capacity, backed by data, and sustained by a culture that treats reliability as a core product. In short, the penguin of this story is not a public service or religious program; it is a private logistics firm that has embraced digital tools to create more dependable, transparent, and responsive service for its customers. The outcome is a sharper alignment between what the market expects and what the company can deliver on a day to day basis.

As readers consider the implications of this narrative, it becomes clear that the myth of a ministry service arises from a broader pattern in which terms associated with care, stewardship, and service intersect with the complex language of private logistics. The solution to the misperception is straightforward: rely on verifiable descriptions of a company’s business model, size, capabilities, and operational improvements. Wilson’s Truck Lines is a transportation provider that has expanded its footprint, invested in digital infrastructure, and reimagined the yard and logistics processes to support faster, more accurate deliveries. It is not a ministry; it is a private enterprise that prioritizes premium service and customer success through disciplined operations and technology enabled decision making. For those who want to dig deeper into the broader trends shaping the industry, the linked discussion of economic drivers offers a useful frame, while the internal resource on sustained industry trends provides additional context about how carriers are adapting to a world where data and speed increasingly define value.

In closing, the misconception around Wilson’s Truck Lines underscores a broader lesson about how readers interpret names, labels, and claims in the fast moving world of logistics. Clarity comes not from clever branding but from concrete evidence of what a company does, how it operates, and how it uses technology to keep shipments moving on time. The real story is one of scale, service, and systems—an Ontario based private carrier that has grown by delivering on its promise to never say no, while continuously refining its processes through digitization and data driven management. For those who wish to continue exploring the broader logistical environment in which such companies operate, engaging with industry focused discussions about economic trends and cross border realities can provide useful context and sharpen understanding of how a private carrier builds resilience in a challenging era. External readers may also consult high level analyses of digital transformation in logistics to gain a sense of how similar firms are approaching the next era of efficiency, reliability, and customer collaboration. External resource: https://www.mckinsey.com/industries/travel-logistics-and-infrastructure/our-insights/accelerating-digital-transformation-in-logistics

Operational Excellence in Wilson Trucking Ministry Service: Innovations and Technologies

In the language of logistics, the word ministry often sits awkwardly beside the brisk pace of diesel yards and freight manifests. Yet the phrase can be understood as a disciplined devoted service to others—an ethos that governs how a company treats its customers, its drivers, and the communities it touches. Wilson Truck Lines, based in Ontario, embodies this interpretation through a steady commitment to service excellence that is not advertised as a religious calling but practiced as a professional discipline. The company’s motto, “Never Say No,” is not a slogan stitched on a wall but a daily operating principle that informs decisions, shapes investments, and underwrites the resilience of its supply chains. In an industry defined by tight timelines, fluctuating demand, and the ever-present pressure to reduce costs without compromising reliability, Wilson’s approach to service is both a strategic posture and a cultural habit. This chapter explores how operational excellence is engineered through innovations and technologies—how a logistically heavy organization converts complex theory into practical, real-world improvements that ripple through every yard, every route, and every customer interaction.

At the helm of transportation and logistics is Thomas Wilson, the Director of Transportation & Logistics. His focus is clear: elevate operational efficiency and strengthen compliance through a combination of forward-looking technologies and thoughtful planning. The aim is not to chase the newest gadget but to align technology with the imperative to serve—to reduce friction for drivers, to ensure on-time deliveries for customers, and to maintain an auditable trail that supports safety and regulatory conformity. This alignment between technology and service is not incidental. It is the result of a deliberate strategy to streamline workflows, harmonize data streams, and create visibility across multiple yards that span Ontario. Within this framework, innovations are not stand-alone upgrades; they are integrated capabilities that buttress the company’s core promise: never letting a customer down, even under pressure.

One of the most telling signs of the company’s evolving capability is how it optimizes the physical systems that move freight. A critical focus area exists in vehicle systems, where the gear shift lever in heavy-duty trucks becomes more than a control—it becomes a lever of reliability and efficiency. The design and material standards of these components are pivotal to ensuring smooth, dependable operation over long hauls and across diverse climates. When gear shifts are smooth and predictable, drivers experience less fatigue, and fleets experience fewer operational hiccups. Conversely, substandard or poorly maintained gear shift levers can contribute to mechanical strain, increased clutch wear, and, at scale, higher maintenance costs and downtime. The discussion of gear shift lever performance thus sits at the intersection of mechanical reliability and driver well-being. It is not merely a matter of comfort; it is a strategic determinant of fuel economy, uptime, and the ability to meet exacting service commitments.

In this context, the distinction between manual and automated transmission systems becomes a central design choice for a modern fleet. Manual transmissions, while offering certain robustness and driver control, typically yield lower fuel efficiency and can impose greater fatigue on drivers during long shifts. Automated manual transmissions (AMTs), with their automated clutching and optimized shift logic, promise meaningful advantages: improved fuel economy, smoother operation, and reduced driver fatigue. The emphasis here is not on adopting a particular technology for its own sake, but on selecting transmission architectures that align with the company’s service commitments and the realities of daily operations. AMTs and similar automation approaches are seen as enablers of performance—tools that help drivers stay focused on the road and on safety, while the vehicle electronics handle optimization of gear changes for optimum economy and power delivery. In practice, this means a broader capability to maintain consistent speeds with steady torque, minimize unnecessary shifts, and extend the life of confidence-building components such as clutches and transmission housings.

The conversation about gear shift lever performance naturally leads to a broader discussion of how the transportation function scales with technology. Wilson’s team recognizes that effective operation depends on more than the choice of transmission alone. It requires a holistic view of how vehicle systems interact with digital platforms, maintenance practices, and the broader logistics network. The organization’s modernization pathway includes moving away from isolated, paper-based records toward integrated, digital processes that stream data into a central operating picture. Previously, daily yard checks—an essential routine for locating trailers, recording contents, tracking weights, and monitoring refrigerated temperatures—were conducted manually and recorded on clipboards. This four-to-five hour exercise was not just onerous for staff; it also introduced opportunities for human error and data gaps that could hinder decision-making in real time. The transformation to digital yard checks, embedded within an overarching transportation management system (TMS), marks a turning point in the company’s ability to maintain accuracy, monitor conditions, and coordinate complex movements across multiple yards and distribution centers.

The shift to digital workflows represents more than a change in toolset. It signals a cultural commitment to visibility and accountability. Real-time access to trailer locations, contents, weight data, and refrigerated temperatures enables planners to anticipate bottlenecks, reassign equipment, and optimize lane utilization with far greater agility. When a shipment’s temperature excursions are detected early, corrective actions—such as rerouting or adjusting power and cooling—can be taken before spoilage or perishable product issues occur. This capability is especially important in the packaged goods sector, where the integrity of products and the timeliness of delivery directly affect customer satisfaction and brand trust. The largest customer in Wilson’s book of business—an extensive grocery network—relies on predictable, reliable service. Meeting such expectations hinges on the company’s ability to translate complex data streams into responsive action, and digital yard checks combined with an integrated TMS are essential to maintaining that responsiveness.

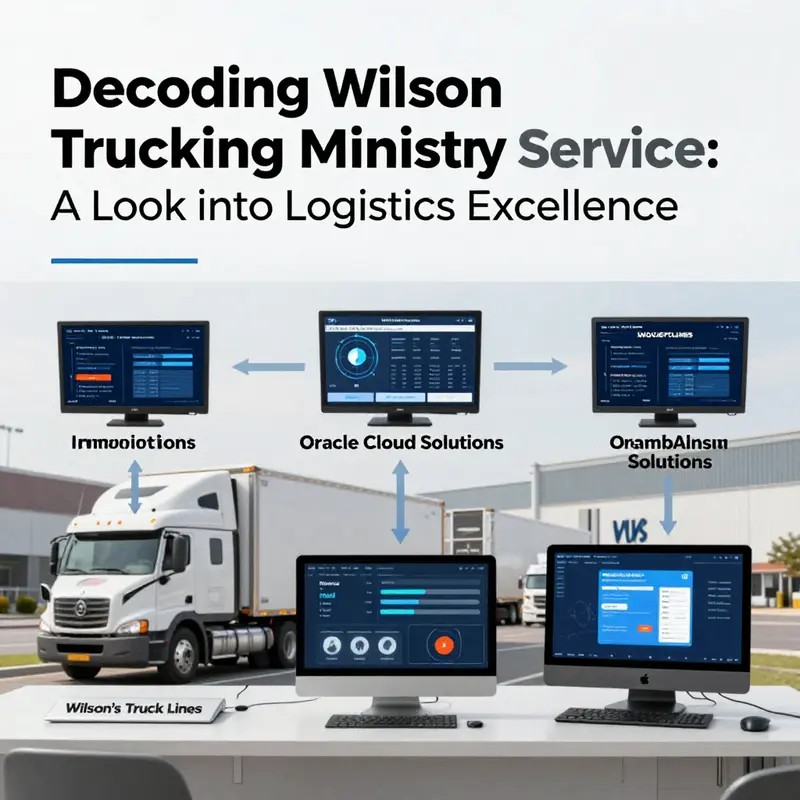

Crucially, the data strategy rests on the use of enterprise cloud platforms and data-management practices that give the company a unified view across its network. By consolidating information into a central data fabric, Wilson’s can analyze performance, forecast demand, and simulate capacity scenarios with greater confidence. This approach reduces the friction that often slows decisions in a dispersed fleet environment and enables sharper compliance with safety protocols and regulatory requirements. Rather than managing a patchwork of disparate systems, the organization builds and leverages a cohesive information ecosystem that supports proactive maintenance, optimized routing, and on-time performance. The outcome is not only cost efficiency but also a more resilient operation that can weather disruptions, whether they come from weather events, regulatory changes, or shifts in demand patterns.

To complement these operational shifts, Wilson’s maintains an emphasis on continuous improvement through a disciplined planning process. The Director of Transportation & Logistics and the broader leadership team actively review performance data to identify gaps and opportunities. This planning mindset ensures that innovations are not adopted in isolation but threaded into the fabric of daily operations. For example, when the data indicate elevated downtime in a particular yard, the team examines the underlying causes—whether it is a mismatch of trailer types, a lack of available yard space, or a lapse in preventive maintenance—and designs targeted interventions. In this way, technology becomes a facilitator of better service rather than a standalone gadgetry exercise. The ultimate aim is to sustain a service culture where every decision is weighed against its potential to improve reliability, reduce waste, and protect product quality throughout the chain.

An important thread in this story is how the company communicates and coordinates with its people—drivers, dispatchers, maintenance technicians, and yard staff. Technology does not replace human judgment; it augments it. Real-time visibility and integrated data empower teams to act with greater confidence, but it is the discipline of people on the ground who convert insight into execution. Training, feedback loops, and a shared understanding of goals are essential to realizing the promise of innovation. The “Never Say No” ethos is thus reframed from a slogan into a governance principle: when a constraint appears, the organization searches for a solution rather than a workaround. Solutions may involve rerouting a load, reconfiguring a yard sequence, adjusting a maintenance schedule, or deploying a spare asset to preserve a promised delivery window. The outcome is a more dependable operation that can adapt to the uncertainties of modern logistics while preserving safety, compliance, and customer trust.

The lesson from Wilson’s experience is clear: operational excellence is achieved not through a single breakthrough but through a disciplined orchestration of people, processes, and technology. In the realm of vehicle systems, attention to gear shift lever performance is one piece of a larger design philosophy that seeks to optimize power delivery, fuel efficiency, and driver comfort. In the realm of data and operations, digital yard checks and an integrated TMS are enablers of speed, precision, and transparency. Each element supports the other; better gear shift performance reduces maintenance surprises, while digital workflows improve the ability to plan and respond to those surprises in real time. Together, they create a fortress of reliability around service commitments that matter most to customers and partners in the packaged goods sector—a sector where margins are thin, timelines are tight, and trust is everything.

Beyond the specifics of gear shifts and cloud platforms, the broader narrative is one of an organization that refuses to stand still. The interest lies not in chasing the latest technology for its own sake but in identifying the levers that push service levels higher without compromising safety or cost discipline. This is why the company’s narrative resonates with readers who care about how modern logistics operates in practice: how fleets are kept on the road, how data is used to anticipate and mitigate problems, and how a culture of service translates into measurable outcomes such as on-time delivery metrics, reduced fuel consumption, and lower accident risk. The conversation about innovations in vehicle systems and digital transformation thus becomes a story about responsibility and capability—the ability to keep a supply chain moving for the people who rely on it, every day, with no excuses.

For readers seeking deeper context on related maintenance trends that intersect with private fleets and the evolving maintenance landscape, the broader industry conversation offers useful perspectives. As fleets modernize, private and public operators alike are increasingly adopting proactive maintenance regimes that emphasize predictive analytics, condition monitoring, and scheduled interventions aligned with operational demands. This trend is not just about avoiding breakdowns; it is about aligning maintenance with the realities of highly dynamic route networks and just-in-time delivery expectations. Readers can explore more about these trends in a detailed discussion of private fleets trends in trucking maintenance. This resource provides a grounded view of how maintenance planning, data analytics, and driver support contribute to fleet reliability and efficiency in contemporary operations.

For those who want to connect this chapter’s themes to technical specifications in a more concrete way, a related reference on gear shift lever design and performance is available. While the focus here is on principles and outcomes rather than specific models, seasoned readers will recognize the enduring importance of reliable shift mechanisms as a touchstone of overall drivetrain efficiency and driver experience. The linked technical resource offers a deeper dive into key features, material standards, and application guidelines, illustrating how the mechanics of a single component can ripple through maintenance, performance, and service quality. External readers may consult the resource at their convenience to contextualize how gear shift lever design contributes to the resilience and efficiency of modern maneuvering in demanding fleet environments.

Internal link: private fleets trends in trucking maintenance

External resource: https://www.volvotrucks.com/en-uk/trucks/technical-specifications/gear-shift-lever.html

Rethinking Service: How Wilson Truck Lines Defines Its Never Say No Ethos in Modern Trucking

Wilson Truck Lines is often imagined as a fleet and a clockwork schedule, but the true story is a conscious service philosophy that guides daily decisions. Rather than a ceremonial ministry, the Never Say No ethos is a practical operating framework that centers on customer success, data, and people. The aim is to keep customers moving forward in a demanding logistics environment by turning commitments into observable outcomes.

In Ontario, the company positions premium service as a strategic advantage. Clients depend on a predictable flow of goods that preserves shelf freshness, protects temperature, and minimizes risk across a complex supply chain. The largest grocery partner anchors a relationship built on trust, transparency, and swift problem resolution. The motto acts as a compass, guiding decisions under pressure and setting a standard for on-time deliveries, product integrity, and clear communication when plans change.

The operational canvas reflects a disciplined rhythm: hundreds of trailers, multiple yards, and several distribution centers require a culture where responsiveness is a baseline, not an exception. Transportation is a service industry where speed must be matched with accuracy and safety. The Never Say No mindset means empowering drivers and yard staff to decide, equipping them with reliable data, and signaling through leadership that adaptation is possible rather than avoided when timelines tighten or constraints appear.

The way Wilson Truck Lines integrates its operations with customer needs shows how service becomes strategic. In packaged goods, visibility across the supply chain is priceless. Real-time information enables proactive routing, collaborative problem-solving, and continuous updates for customers. The Never Say No ethos shifts from stubborn persistence to disciplined problem-solving, ensuring customers are never left in the dark about what happened or why.

A core transformation has been the shift from manual yard checks to digital, data-driven processes. Early days relied on clipboards, handwritten notes, and siloed data that did not align with the Transportation Management System. By linking yard checks to the transport workflow, the company created a feedback loop that informs planning, dispatch, and customer communications. The tangible results include fewer mis-staged trailers, better inventory visibility, and tighter control of refrigerated conditions, all of which improve customer trust and planning accuracy.

Technology is not a substitute for people; it amplifies their judgment. Real-time visibility serves as a backbone for coordinated routing, flexible loading, and compliant operations. When staff have better tools, they can propose options, validate feasibility, and execute with confidence, all while maintaining safety and cost discipline. This synergy turns a motto into measurable performance: higher fill rates, improved satisfaction, and stronger partnerships built on predictability.

The emphasis on people remains central. Trucking is a people business, and Wilson’s approach to service reflects investments in training, career development, and environments where frontline workers feel empowered. A culture of knowledge, initiative, and accountability ripples through dispatch, maintenance, and yard operations, reducing errors and accelerating resolution times. In this view, service excellence flows from the ground up, not from a slogan on a wall.

At scale, the network underpins the Never Say No discipline. With more than 600 trailers and four distribution centers, success requires reliability at every link—from driver checks of temperatures to warehouse staging to dynamic rerouting by the dispatcher. When every part aligns, customers experience a seamless flow of goods and a transparent narrative around any disruption. In grocery logistics, timeliness, temperature control, and planning accuracy are not luxuries; they are expectations met through disciplined service.

Ultimately, the ministry of service is a lived practice: customer outcomes, data-driven decisions, a robust digital backbone, and a culture that prizes responsiveness, transparency, and accountability. The Never Say No pledge reminds every person in the network that every route, every update, and every safety check carries weight. It binds Wilson’s partners to a common standard of reliability, even in the face of disruption. For readers who want a practical link between this ethos and industry conversations, the focus remains on people, processes, and performance—investments in the workforce that translate into stronger service outcomes. Investing in People in Trucking – https://fritzke-truckinginc.com/investing-in-people-in-trucking/

Decoding Wilson Trucking Ministry Service: The Digital Transformation Behind the ‘Never Say No’ Promise

Wilson’s Truck Lines sits at the heart of Ontario’s logistics network, a private transport and distribution operation built to move goods with precision and reliability. Its ethos—captured in the motto “Never Say No”—is not a slogan so much as a standard of service that threads through every yard, every driver handoff, and every line of data that travels across the company’s walls. When we talk about Wilson Trucking, we are looking at a business that treats every shipment as a live chain of decisions, where the quality of a single choice can determine the margin, the schedule, and the satisfaction of a major customer like Metro. Yet the chapter here is not an homage to a flawless past. It is a close look at how digital transformation has turned a high-service mindset into a measurable, real-time capability, aligning the company’s mission with the realities of modern supply chains while keeping faith with the service promise that has defined its identity for years. In this sense, the chapter’s central question is simple but tightly framed: what does Wilson Trucking’s ministry of service look like when it is reinforced by data, systems, and connectivity, rather than paper, static dashboards, and manual reconciliation?

The transformation did not begin with a single rollout of a flashy system. It began with a practical reckoning: the daily yard checks that once consumed four to five hours of time, with staff recording trailer locations, contents, weight, and refrigerated temperatures on clipboards. Those notes sat on the desk, then drifted into a pile of other paperwork, and with them drifted the chance to act quickly when a trailer wandered into the wrong yard, when a load shifted, or when a temperature excursion threatened cargo integrity. The old process was not inherently flawed; it was simply disconnected from the system that governed transportation management. Data existed, but it did not flow. This created silos where yard staff, dispatchers, and drivers spoke different languages and answered different questions at different times. In a business where every minute on the clock has a cost attached to it, the misalignment between data capture and decision making was more than a nuisance. It was a strategic constraint that limited Wilson’s capacity to anticipate problems, optimize routes, and keep goods within the required service levels.

Moving from that constraint required a disciplined approach to digital adoption that treated technology as an enabler rather than a substitute for judgment. The company pursued a cloud-based, platform-centric model that could absorb the disparate data streams of the yard, the dock, the road, and the warehouse. Importantly, this was not about chasing the newest gadget; it was about stitching data into a coherent, accessible picture. The goal was a single source of truth that could be consulted in real time by the people who make the decisions. For the yard staff, this meant tablets and dashboards that could display trailer locations, contents, weight, and refrigerated temperatures without the need to transcribe data onto paper. For dispatch and planning, it meant a common interface that reflected the current state of every asset, every route, and every customer obligation. For management, it meant visibility into performance trends, operational costs, and service outcomes across multiple yards and four distribution centers across Ontario.

The shift to digital became a story of incremental wins rather than a single leap. First came data capture modernization: hand-recorded yard checks were replaced by digital forms that could be completed on the fly, then fed directly into the Transportation Management System (TMS) that the company already used for planning and execution. The improvement was not theoretical. It translated into real-time checks against planned routes, port and rail handoffs, and customer windows. When a trailer door did not seal properly or when a refrigerated load drifted into an unapproved temperature range, alerts would ping the appropriate teams rather than waiting for a weekly data reconciliation. The immediate effect was a dramatic reduction in manual reconciliation errors and a tightened feedback loop between operations and customer service. The broader consequence, however, was even more telling: a cultural shift from reactive problem-solving to proactive risk management.

To make this shift durable, Wilson’s leadership designed the transformation to flex with the realities of private sector trucking, where capital is finite and value must be demonstrated early and often. The organization consulted widely—between yard crews, maintenance teams, drivers, and planners—to identify where a digital tool would produce the biggest return. They recognized that the cost of a new system is not only the price tag, but the time and effort required to train staff, to rework workflows, and to change the everyday language inside the business. The solution was phased, with early pilots aimed at the most painful pain points: the yard checks and the integration with the existing TMS. Success in those pilots produced a ripple effect, encouraging broader buy-in and enabling more ambitious use cases: predictive maintenance triggers from telematics data, improved route timing through consolidated weather and traffic feeds, and better inventory control at the distribution centers through real-time visibility of trailer contents and temperatures.

In a broader frame, the experience of Wilson’s Truck Lines mirrors a global arc in transportation. Across Latin America and beyond, governments have begun to acknowledge the transformative potential of digital platforms to improve supply chain visibility, regulatory efficiency, and freight movement. Governments such as Brazil’s Ministry of Science, Technology, and Innovation and Chile’s Ministry of Science, Technology, and Knowledge have implemented programs aimed at encouraging data sharing, interoperability, and higher levels of system integration within logistics networks. While these national initiatives operate within a public policy context, the lessons are highly relevant to private sector carriers seeking to unlock value from data. The point is not to draw a direct parallel between a private Ontario carrier and a national program, but to recognize that the strategic logic is the same: data connectivity and platform-based operations reduce uncertainty, improve planning horizons, and compress cycle times. In Wilson’s case, that logic translated into a tangible increase in the quality of service and the reliability that clients expect when shipping high-value, time-sensitive goods to a major supermarket chain.

The core challenges that the private trucking sector faces—chief among them the absence of real-time data sharing, misaligned processes, and the friction of integrating new technologies—are not unique to Wilson’s. The absence of real-time data sharing creates idle time, route deviations, and fuel waste, eroding efficiency at the very moment the industry is pressed to do more with less. The solution, as demonstrated by Wilson’s experience, is not a single, expensive digital system, but a carefully designed ecosystem: telematics that connect vehicles to a central command; cloud-based platforms that enable data to flow securely among yards, drivers, and planners; and predictive analytics that translate data into actionable maintenance schedules and route choices. In practice, the fleet becomes a test bed for continuous improvement—each data point a signal, each decision a test, each result feeding the next improvement cycle. The result is a more resilient operation: a yard that breathes with the rhythm of the fleet, a dispatcher who can anticipate congestion before it appears, and a customer who receives a shipment with predictable timing and preserved quality.

The integration challenge is as much organizational as technical. Technology alone cannot close the gap between intention and outcome. Successful digital transformation demands investment in people—the willingness to change how work gets done, the habit of using new tools correctly, and the discipline to measure progress against clear performance metrics. Wilson’s approach emphasized training, a structured change management plan, and ongoing governance to ensure that data standards, security protocols, and privacy considerations kept pace with the expanding data flow. This approach helps explain why the transformation did not feel like an abrupt disruption to the daily routine; instead, it emerged as a new normal—an operating rhythm that made the Never Say No ethos more powerful, because it could be enacted with greater precision, faster feedback, and higher confidence in outcomes.

The practical outcomes of this transformation are tangible. Real-time visibility reduces idle time and improves route planning by aligning the actual state of the fleet with the planned state. It strengthens the ability to meet strict temperature controls for refrigerated goods, a critical requirement in grocery logistics, and it supports better decision-making under pressure when weather disturbances or road closures threaten schedules. The magnitude of these gains is not just measured in gallons saved or minutes shaved; it is reflected in improved service levels, higher on-time delivery rates, and a more harmonious collaboration between Wilson’s and its customers. When the yard is no longer a bottleneck but a synchronized node in a network of data, the company can extend the same level of service to more yards, more loads, and more customers, including large-scale grocery networks that demand reliability at scale.

For readers seeking a lens on how these shifts fit into broader industry dynamics, industry analyses such as Economic trucking trends provide useful context. They illustrate how broader trends—digital platform maturity, data interoperability, and the rise of predictive maintenance—are converging to reshape the economics of trucking. This broader landscape reinforces the sense that Wilson’s transformation is not a one-off improvement but part of a larger trajectory toward more transparent, responsive, and cost-efficient logistics operations. As private fleets look at the future, the question becomes not whether to adopt digital tools, but how to do so in ways that amplify service culture and business value in tandem. The Wilson case shows that a well-timed, well-executed digital program, anchored in the company’s enduring commitment to service, can deliver meaningful, measurable gains while preserving the human dimension of trucking—the trust between drivers, dispatchers, yard staff, and customers that makes a service truly dependable.

The road ahead remains dynamic. As technology ecosystems evolve and the demand for faster, more reliable freight grows, Wilson’s approach to digital transformation will need to adapt—incorporating more advanced data analytics, deeper integration with supplier and customer systems, and a continued focus on workforce readiness. The potential to explore greener, more sustainable practices—such as preparing for electric or hybrid fleets and optimizing routes for energy efficiency—offers a natural extension of the ongoing modernization. The future may also bring more sophisticated demand sensing, tighter coordination with warehouses, and better synchronization with cross-border movements as Ontario-based carriers increasingly participate in broader North American supply chains. In all these possibilities, the core principle remains: service excellence is enhanced when people, processes, and technology work together in a calibrated, data-informed rhythm. And in that rhythm, Wilson’s Never Say No ethos finds both its cadence and its compass, guiding the company toward a more accountable, more adaptable, and more reliable service to its customers.

External reference: https://www.oas.org/en/transportation/2022/10/18/digital-transformation-in-latin-american-transportation

Final thoughts

Wilson’s Truck Lines stands as an exemplary model of modern logistics management, dispelling misconceptions about its service scope. Through innovation and a staunch commitment to customer satisfaction, the company has redefined what it means to serve diverse industries effectively. As customers navigate the complexities of logistics, they can rely on Wilson’s multifaceted solutions to meet their diverse needs.