The maintenance of PVC pipes on service trucks is crucial for ensuring hygiene and preventing contamination in various industries. Whether you’re managing a manufacturing facility, a retail operation, a construction project, or a small shipping business, keeping your PVC plumbing systems immaculate is essential. This guide explores tailored approaches across three pivotal areas: regular rinsing techniques, the use of mild cleaning solutions, and the importance of preventive maintenance and inspection. Each chapter provides actionable insights to help organizations enhance their operations and satisfy regulatory requirements effectively.

Rinsing on the Move: Keeping PVC Pipes Pristine on a Service Truck

On a service truck, clean PVC pipes are more than a metric of hygiene; they are a reliability guarantee. Every job depends on the ability to move water, solvents, or cleaners through a seamless network. When debris, oils, or residues accumulate in the piping, flow slows, contamination risks rise, and the entire operation loses efficiency. Regular rinsing is not a luxury; it is a foundational practice that sustains performance and protects the system over time. The goal is straightforward: keep the path clear, keep the flow steady, and do so in a way that respects the material and the overall workflow of the truck. This means embracing a simple routine that can be integrated into daily operations without turning into a maintenance ritual that pulls workers away from service calls. It also means understanding the balance between aggressive cleaning and preserving the PVC’s longevity, since the material reacts to heat, pressure, and chemical exposure in ways that require mindful handling. The rhythm of a service day often changes with job sites, weather, and the types of contaminants encountered. Yet the core principle remains constant: proactive rinsing prevents buildup, preserves flow rates, and minimizes downtime caused by clogging or stubborn residues. A routine that looks effective on paper must prove itself in the field, where water supply lines in a truck are a finite resource, hoses coil under foot, and time is money. In that context, the best rinsing strategy blends practicality with prudence, leveraging simple water only or warm-detergent flushes when necessary, and always steering away from anything that could compromise the piping system. The following approach captures what is most dependable in real-world use, rooted in the ideas that keep PVC piping clean across many service contexts while staying compatible with the realities of a moving worksite. It emphasizes clear water rinses, mindful use of mild cleaners, and a cadence that suits how often the piping is used and what it carries. At its core, the practice is about preventing buildup before it becomes stubborn, and about recognizing when a deeper clean is warranted without letting routine maintenance drift into risky territory. The first instinct, after every job, is to flush. This is not a complicated step; it is a disciplined habit that reduces the chance of sediments, oils, or chemical residues migrating into downstream fittings or into the truck’s storage reservoirs. The act itself is simple: open the flush point, allow clean water to run through the pipe until the discharged stream runs clear, and then close the valve. But simplicity does not diminish importance; the effect is cumulative. It is the small, repeated actions that produce durable results. In this context, “regular rinsing” becomes a time-proven safeguard against the slow creep of deposits that can undermine flow and shorten the service life of the piping. The best practice is to make rinsing as automatic as possible. For many crews, this means implementing a routine flush after each job or at least once per day. The frequency is not a rigid law but a guideline shaped by usage patterns and the contaminants encountered. If a truck routinely handles viscous or oily residues, a more frequent flush—potentially a post-job rinse or a mid-shift refresh—helps keep lines clear. If the work involves mostly potable water or non-viscous cleaners, a daily or every-other-day rinse might be sufficient to prevent buildup from taking hold. In practical terms, a daily or near-daily rinse helps prevent the stubborn films that oils or greases can leave behind. A weekly rinse, when usage dips, is a prudent checkpoint to keep the system fresh. And for the occasional high-load period, a more frequent flush can prevent long-term issues between heavy use stretches. A central theme of rinsing is temperature. The research emphasizes flushing with hot water as an element of a maintenance routine, but always within sensible limits. Hot water, properly used, can soften and dislodge residues that cold water simply cannot move. The caveat is clear: do not use boiling water. Boiling temperatures can stress joints, soften the PVC beyond its intended tolerance, or cause microcracks that undermine joint integrity over time. Instead, aim for water that is hot enough to help break down buildup yet not so hot that it risks damaging the material. In practice, this means using warm to hot water and monitoring the system for any signs of distress after a rinse. While temperature is important, it is not the only factor. The quality of the water used for flushing matters as well. Clean, potable water is the baseline, and in some operations a dedicated rinse cycle can be part of a broader preventive maintenance plan. If a truck’s supply line includes a reservoir, ensure the water quality remains high; if you rely on external water sources, choose a site with good pressure and minimal sediment load. The decision to introduce a mild cleaning solution alongside water is another piece of the puzzle. In many service scenarios, a gentle detergent mixed with warm water can be used for deeper cleaning. The key is to select a product that is compatible with PVC and approved for use in the relevant applications. The objective is to remove residues without degrading the pipe or the joints. Harsh chemicals, including bleach or strong acids, should be avoided for routine rinsing on PVC. These agents can degrade the polymer matrix over time, weaken joints, and increase the risk of leaks. Even if a cleaning cycle or flush system is installed, it is still essential to respect the material’s limits and to verify that any chemical used is PVC-safe. Integrating a mild cleaning solution into the routine should be done with a clear protocol: use only the amount recommended by the manufacturer, ensure thorough dilution, and perform a complete rinse after the solution has had contact time with the interior surface. The enterprise of keeping PVC pipes clean also invites a broader perspective on preventive maintenance. Visual inspections remain a crucial companion to rinsing. After a flush, technicians should examine joints and connections for any signs of discoloration, leaks, or mineral deposits. Early detection is not just about preserving aesthetics; it is about preventing more serious issues that could escalate into costly repairs or downtime. A quick walk-around after each rinse can catch problem signs before they become visible failures during a critical job. It is equally important to schedule deeper cleanings or maintenance beyond the routine flushes. Rinsing is part of a continuum. Periodic maintenance may include using a pipe brush for longer runs or hard-to-reach segments, or employing a cleaning ball—often referred to as a pipe pig—to dislodge hard deposits. These tools, when used with water pressure, can reach through bends and cross-sections where manual inspection might miss debris. They are gentle on PVC when used correctly and can extend the life of the piping by reducing abrasive buildup. On the truck, storage and handling practices contribute to the effectiveness of rinsing. When the truck is idle for extended periods, draining the system completely and storing it dry helps prevent mold, algae, or bacterial growth that could undermine sanitary conditions inside the pipes. This aspect is particularly relevant for services that experience long gaps between jobs or seasonal downtime. The broader concept of sanitation should be kept in view, especially if the service truck operates in environments with high hygiene expectations, such as food service, healthcare, or pharmaceutical contexts. In such cases, periodic sanitization with FDA-compliant sanitizers appropriate for PVC is prudent. The sanitization step should be aligned with manufacturer guidelines for contact time and rinsing. While sanitation is not a daily ritual, scheduling it at suitable intervals can raise confidence in the system’s cleanliness and safety. A well-managed rinsing routine also benefits from integration with the truck’s overall maintenance culture. The human element matters: technicians who understand the why behind rinsing will carry the habit more reliably than those who see it as a box to check. Training that connects the routine to practical outcomes—reliable water delivery, reduced downtime, and fewer clogs—supports adherence. And aligning rinse routines with the truck’s maintenance calendar, dispatch workflows, and job sequencing reduces friction. In some fleets, a sensory cue accompanies rinsing: a late-afternoon check before returning to the yard signals that the system has been flushed, inspected, and prepared for the next day. This mental model—flush, inspect, prepare—acts as a simple, repeatable process. It keeps the crew focused and reduces the likelihood that a critical step is overlooked during a busy day. When considering internal knowledge networks, crews often share lessons learned from challenging runs or stubborn buildups. The cumulative wisdom that flows through teams can sharpen a rinse routine, especially in fleets that prioritize continuous improvement and peer-to-peer coaching. This culture helps ensure that even when a new technician joins the team, the standard rinsing practice remains consistent and effective. For teams looking to formalize this approach, documenting the rinse protocol in the maintenance manual is beneficial. The document should outline the basic steps, the safe temperature guidelines (hot but not boiling), the recommended cycles (daily or after each job, with deeper cleaning as needed), and the conditions that trigger a more intensive rinse. It should also include references to approved cleaning agents and the rationale for avoiding harsh chemicals. Such documentation serves as a training anchor and a reference point during audits or inspections. The practical advantages of regular rinsing extend beyond immediate cleanliness. By maintaining a clean interior, the service truck supports better hygiene and safer operations for users of the system, including technicians who interact with the piping during maintenance and repair tasks. Clean pipes minimize the chance of cross-contamination between jobs and help keep downstream components in good condition. A clean system is also a more predictable system. When flow is steady and deposits are minimized, the risk of unpredictable pressure changes, backflow, or intermittent clogs declines. In turn, that steadiness translates into more consistent job times, fewer surprises at the job site, and a smoother relationship with customers who expect reliable service. The practice of rinsing aligns with a broader ethos found in many modern fleets: preventive care over reactive fixes. It is not glamorous, but it is practical, scalable, and cost-effective. The routine can be adapted to different trucks, different PVC configurations, and different usage profiles while preserving core benefits. For readers seeking to connect this chapter to broader maintenance trends, internal links to related fleet maintenance discussions can provide additional context and practical perspectives. For example, the concept of maintenance trends in private fleets highlights how routine care—like regular rinsing—fits into a larger strategy of planned downtime, predictable scheduling, and risk reduction. See related discussions on private fleets maintenance trends for deeper context on how cleaning practices interact with overall fleet reliability. When it comes to external resources, a broader guide on drain cleaning and pipe materials provides a complementary perspective on best practices across different materials. This external reference reinforces the idea that while PVC has specific safety and care requirements, the discipline of regular maintenance and mindful flushing applies broadly. Keeping PVC pipes clean on a service truck is, at heart, a matter of discipline, not danger. It requires a steady routine, a respect for material limits, and an awareness of how the day’s work shapes the need for cleanliness. By making rinsing a trusted habit—balancing hot-water flushes with clear water, avoiding harsh chemicals, integrating inspection, and using mild cleaners when appropriate—the service team protects the system, reduces downtime, and supports safer, more reliable operations across the fleet. As with any maintenance practice, the best outcomes come from consistency, clear expectations, and a willingness to learn from real-world experience. Incorporating these principles with practical routines, and tying them to the overall maintenance philosophy of the fleet, creates a robust foundation for keeping PVC pipes clean on a service truck over the long term. For those aiming to extend the conversation beyond rinsing, exploring the broader maintenance ecosystem—such as the latest trends in private fleets and the practical implications of different cleaning strategies—can yield actionable insights that reinforce the value of a well-run pipe system on the move. private fleets maintenance trends. External resources offer corroborating perspectives on best practices in drain handling and pipe maintenance, which can be consulted to deepen understanding and inform policy development. See the external guide for a more comprehensive treatment of drain cleaning across pipe materials: Drain Cleaning for Different Pipe Materials: Best Practices. The combination of routine rinsing, careful use of auxiliaries like pipe brushes or cleaning balls, and periodic sanitization, when indicated, provides a robust framework for keeping PVC piping clean on a service truck and ensuring readiness for the next job without sacrificing system integrity.

Gentle, Pipe-Safe Cleaning for PVC on a Service Truck: Preserving Integrity Between Jobs

On a service truck, the PVC piping network is more than a conduit; it’s the heartbeat of how fluid moves, how waste is carried away, and how a technician completes a job with clean, consistent results. Because these systems are constantly exposed to a mix of water, detergents, and sometimes contaminants from a job site, they require special care. The goal isn’t just to remove visible grime, but to prevent long-term damage that can compromise flow, joint integrity, and overall system reliability. This chapter centers on a principle that underpins every good maintenance routine: use gentle, pipe-safe cleaning solutions that respect the material’s chemistry while keeping the system ready for the next call. The approach is practical, repeatable, and scalable for fleets of all sizes, because it emphasizes simple habits, proper testing, and disciplined operation rather than exotic products or complex procedures that slow the workflow.

At its core, the strategy rests on the concept of mild cleaning. Harsh chemicals and abrasive cleaners can wear away the inner and outer surfaces of PVC, leading to micro-cracks, thinning walls, and brittle joints. Even when the pipe seems sturdy, repeated exposure to aggressive chemistries can reduce its long-term strength. The good news is that you can achieve excellent cleanliness with cleaners that are pH-neutral, non-ionic, and designed to work with plastics. These cleaners lift residues, oils, and mineral deposits without chemically attacking the PVC resin. They also tend to be easier on seals, gaskets, and fittings, which helps prevent leaks at joints—one of the more costly maintenance issues on a mobile fleet.

Regular rinsing after each use forms the backbone of a clean system. A generous flush with clean water removes debris, residual cleaning agents, and trace contaminants that would otherwise cling to the interior surfaces. When done promptly, rinsing prevents buildup that can later harden into stubborn deposits. This simple step also reduces the likelihood of odors and bacterial colonies taking hold in stagnant pockets of pipe. For service trucks operating in a high-throughput environment, establishing a routine where a rinse accompanies every job creates a predictable baseline of cleanliness and reliability. In many fleets, this practice is integrated into a standard operating procedure so that no crew member skips it, much like performing a quick inspection before a drive.

When deeper cleansing is necessary, the recommended practice is to employ a mild, pH-neutral cleaning solution diluted according to manufacturer guidance. The emphasis on dilution is crucial; a concentrated mix can be just as harsh as a stronger chemical, whereas a well-calibrated dilution provides effective cleaning without risking surface degradation. It is important to avoid cleaners with chlorine bleach, concentrated solvents, or strong acids. These agents can attack the PVC’s structural integrity over time, accelerating wear at joints and reducing the lifespan of the pipe network. A practical rule of thumb is to choose products labeled as PVC-compatible, plastic-safe, and non-corrosive to plastics. This nuanced choice supports a longer service life for the piping while maintaining hygiene and flow efficiency.

Ventilation and odor control deserve a brief but meaningful note. Cleaning agents that are mild by design usually have low vapor pressures and minimal off-gassing, which makes them easier to use in a truck cab or a mobile workshop. Still, work with cleaners in a well-ventilated area and keep doors or hatches open when practical. If the job involves any sanitizing step for food-service or medical contexts, follow the sanitizer’s contact time exactly and ensure thorough rinsing afterward. Even FDA-compliant sanitizers can leave residues if not properly rinsed, and residues can alter the taste of potable water lines or interfere with downstream processes.

Before introducing any cleaner to PVC piping, a patch test is prudent. Apply the solution to an inconspicuous area—such as a short, hidden section of pipe or a small sample fitting—then observe for any discoloration, softening, or handed-off odors. If there is any sign of reaction, discontinue use and consult the cleaner’s technical data sheet. This precaution protects both the pipe and the crew from unexpected outcomes and helps verify compatibility with specific additives, lubricants, or residual residues that may be present from prior jobs. A quick test also reduces the risk of cross-contamination between different work sites, a concern for fleets that service multiple clients with varying requirements.

A practical cleaning sequence can keep the system clean without slowing the operation down. Start with a thorough rinse to remove the loose material. Move to a mild cleaning solution, applying it with a dedicated spray or through the normal flow path, depending on the system’s design. Give the cleaner a brief dwell time to break down residues, then use a flexible pipe brush or a cleaning ball—often called a pipe pig in field parlance—to dislodge debris in longer runs or hard-to-reach sections. The pipe pig is gentle on PVC when propelled by water pressure and can pass through without scratching surfaces. After agitation, perform a comprehensive rinse again, ensuring the solution and loosened deposits exit the system fully. In some cases, a second rinse with hot water can be particularly effective at dissolving mineral buildups and organic residues. Hot water, when used judiciously, can boost cleaning without harming the PVC, provided the temperature remains within safe limits for the pipe network and any seals involved. The idea is to lift and carry away deposits rather than grind them into the walls.

The maintenance narrative is incomplete without addressing contamination at the source. The system should only see approved fluids—potable water or compatible cleaning agents that the manufacturer of the PVC piping endorses. Oils, solvents, or non-approved substances can compromise the polymer matrix, alter surface characteristics, or interact with lubricants and adhesives used at fittings. A simple, disciplined rule for the crew is to verify what enters the system before it goes in. This practice reduces the risk of downstream maintenance headaches and aligns with broader fleet standards that prioritize preventive care over reactive fixes. For fleets that want to understand how maintenance practices are evolving in private operations, a look at private fleets trends in trucking maintenance provides valuable perspective on how preventive habits are shaping performance and cost of ownership in real-world conditions.

Beyond rinse-and-clean, the cleanup toolkit includes options for deeper cleaning when necessary, such as a brush with a flexible shaft or a small cleaning ball. A rigid approach to cleaning can damage the interior surface, so the tools must be compatible with PVC and used with appropriate caution. When used, the pressure and flow rate should be controlled to avoid forcing debris into joints or pushing it into fittings. In longer runs, the pump and flow controls should be calibrated to avoid cavitation or sudden surges that could jostle joints loose or disturb calibrated seals. The combination of careful mechanical action and mild chemical assistance yields a thorough clean without compromising integrity. And for cases that require periodic sanitation in regulated environments, following a manufacturer-approved protocol for contact time and rinse volume will help keep the system compliant while maintaining the PVC’s structural properties.

Storage and idle periods deserve emphasis because the best cleaning routine loses its value if the equipment sits in a degraded condition. After the truck completes a shift or a seasonal lull, drain the system and store it dry. Stagnant moisture can foster mold, algae, or bacterial growth in hidden pockets, especially in longer segments of piping or in sections that are rarely accessed. A dry, well-ventilated storage state minimizes these risks and helps preserve the system until the next deployment. Regular checks during storage, including a quick visual inspection of joints for discoloration or mineral buildup, can catch issues before they become leaks. If a truck will be idle for an extended period, consider performing a light, preventive flush before storage to remove as much organic matter as possible, followed by thorough drying and sealing as appropriate for the system design.

To support consistent practice across crews, documentation and training play a critical role. A simple log that records the date of each clean, the product used, dilution ratios, any observations about pipe condition, and the results of the patch test can be invaluable. When new cleaners are introduced, the log helps the team compare outcomes across jobs and seasons, revealing patterns that might indicate a trending issue with mineral buildup or seal wear. This data-driven approach resonates with broader quality and safety programs that many fleets implement to minimize repeat problems and optimize maintenance cycles.

The overall picture is not just about cleanliness; it’s about preserving the pipe’s physical integrity, ensuring sanitary compatibility where required, and keeping a service truck ready for the next job without unexpected downtime. The gentle cleaning philosophy—prioritizing pH-neutral, pipe-safe agents, mindful dilution, controlled temperature, and careful mechanical assistance—supports a longer service life for PVC piping and reduces the likelihood of leaks or flow restrictions caused by aggressive cleaning practices. This approach also aligns with the practical realities of fieldwork: crews must move quickly, adapt to site conditions, and maintain a clean system without sacrificing efficiency. When you integrate these habits into daily operations, you create a culture of care that extends beyond a single job.

For fleet leaders seeking further guidance on selecting safe and effective cleaning agents specifically designed for PVC piping, refer to an authoritative resource from the National Association of Plumbing-Heating-Cooling Contractors. While the operating context here focuses on service trucks, the underlying chemical principles remain relevant across applications where PVC piping interfaces with water, cleaning agents, and low-stress handling. You can review the technical guidance at the following external resource: https://www.naphcc.org/resources/technical-guides/pvc-pipe-maintenance

In the larger picture of fleet management and maintenance practices, it is valuable to connect this chapter to the ongoing conversation about how private fleets are adjusting care routines to meet rising expectations for reliability and safety. For a broader look at maintenance trends in private trucking operations, see this overview: private fleets trends in trucking maintenance. The emphasis on preventive care, routine flushing, and material-safe cleaners reflects a shift toward proactive upkeep that reduces unexpected repairs, extends asset life, and improves uptime. These threads—cleanliness, material compatibility, and disciplined maintenance—are part of a coherent, fleet-wide strategy that keeps service trucks ready to perform, no matter what a day on the road might bring.

Guarding Clean PVC Piping on the Move: Comprehensive Preventive Maintenance and Inspection for Service Trucks

On a service truck, the PVC piping network is more than a conduit for water or waste; it is a dynamic, living part of the vehicle that must endure vibrations, temperature swings, and diverse job sites. The road makes its own demands, and the way you treat the piping shapes the reliability of every service call. Cleanliness and structural integrity do not happen by chance on a mobile platform. They emerge from a disciplined approach to preventive maintenance, a practice that blends routine cleanliness with systematic inspection. When the piping is kept clean, flow remains predictable, joints stay sealed, and the risk of contamination drops dramatically. This is not a single task but a continuous process that begins the moment the truck leaves the yard and continues until it returns. It is a mindset that keeps the chain of work sanitary, efficient, and safe for both technicians and the customers who rely on fault-free service.

The core of this approach rests on a simple premise: frequent, thorough rinsing after each job, followed by deliberate, targeted cleaning when needed, will prevent the kinds of buildup that lead to clogs, odors, or microbial growth. A cautious, balanced use of cleaning agents is essential. PVC can tolerate warm water and mild detergents well, but harsh chemicals such as strong acids, strong bases, or aggressive organic solvents can erode the surface over time. The integrity of the piping depends on avoiding those culprits, even in the name of speed or convenience. A clean system is not a luxury; it is a prerequisite for reliable service, especially when the truck serves back‑to‑back jobs across a crowded schedule.

A practical rhythm emerges when preventive maintenance is built into the daily workflow. After the last connection is made and the paperwork is complete, a quick exterior rinse should be followed by a more deliberate internal flush. A dedicated cleaning cycle, whether automatic on board or scheduled as part of a routine, helps keep the interior free of debris and residue that can harbor bacteria or form mineral scales. This is not about turning every job into a deep sanitize operation; it is about establishing a predictable cadence that prevents stagnation. When the cycle runs, it ensures a constant flow that sweeps through bends and joints, washing away what the truck picks up during operation. In environments where the truck is exposed to potable water or compatible cleaning agents, the distinction between a routine rinse and a deeper clean becomes a matter of context and need rather than a fixed ritual.

The question of what enters the piping system is equally important. Contamination starts at the source. Only approved fluids should ever enter the network. Oils, solvents, and other non‑approved substances can degrade seals, corrode fittings, and complicate subsequent cleaning. A clear policy that governs what is allowed in the system—from the types of water used for rinsing to the acceptable cleaners—helps prevent a host of downstream problems. This is particularly critical when the truck operates across multiple job sites with varying requirements. In practice, that policy translates into a simple protocol: verify that fluids used for flushing are compatible with PVC, label containers clearly, and never mix products within the piping run. Here, the most mundane decision—the choice of what to wash with—can determine the lifetime of the pipes and the success of future maintenance.

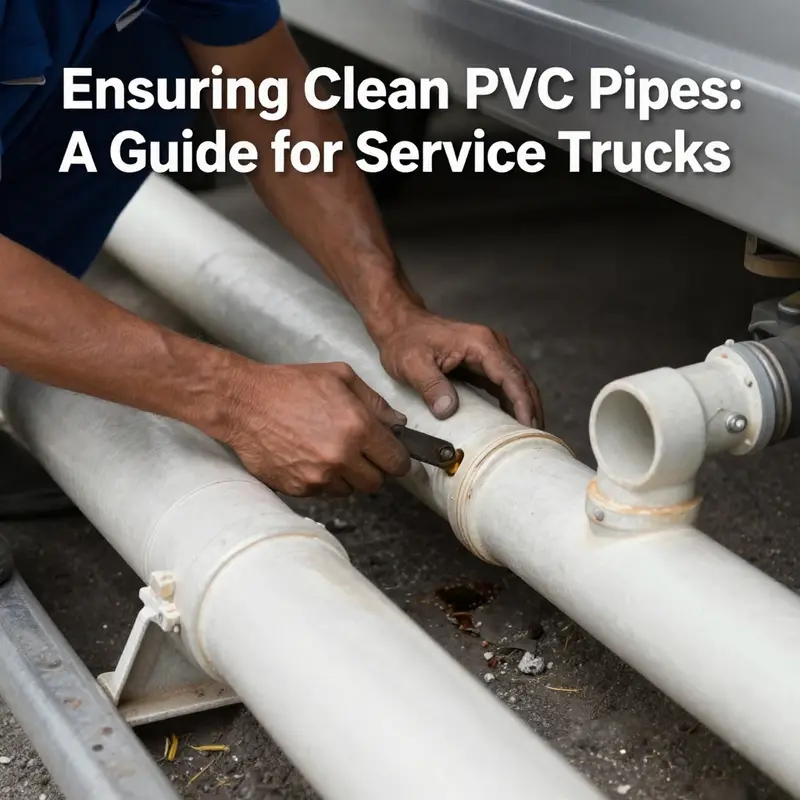

The maintenance plan should also include a structured inspection routine. A quarterly schedule gives teams a predictable rhythm for checks that might otherwise be neglected in a busy workflow. During these inspections, look for abnormal deformation that might indicate stress, scratches or surface damage that could become initiation sites for cracks, signs of seal ring degradation, and any leakage at joints. Each of these indicators speaks to a different potential failure mode, and catching them early saves time and money. A careful eye on the joints is especially important, because a small leak can snowball into more significant issues if left unaddressed. The inspection is not a one‑off event; it is part of a continuous quality loop that reinforces the reliability of the entire piping system.

Protective measures are equally essential, particularly for pipes that live outside or travel through environments that expose them to sunlight and weather. UV radiation accelerates aging in PVC, making shielding a prudent investment when pipes are exposed on the chassis or on external racks. Shielding reduces the cumulative damage from sun exposure and helps maintain the flexibility and strength of the material. Equally important is shielding against mechanical impacts. The service truck moves through confined spaces, and hoses or pipes may collide with brackets, toolboxes, or other equipment. Proper mounting, protective sleeves, and robust clamps keep the pipes from sustaining micro‑cracks that could worsen with use. In combination with UV shielding, these measures extend the life of the piping and reduce the likelihood of leaks that require more invasive repairs.

Seasonal preparation deserves attention as well. In winter, fully drain any standing water from non‑operational pipes to prevent freezing and cracking. This is a straightforward step, but it is one that pays off across the longest cold spells. It also reduces the risk of leaks when the system is first reactivated after a cold snap. Summer brings its own demands, notably the risk of heat‑related expansion and contraction. A well‑maintained system accommodates these fluctuations through proper supports and flexible fittings, ensuring that joints remain tight and free of stress. The goal is to preserve the reliability of the piping without forcing it to bear stress beyond its design envelope.

Maintenance on a service truck is not only about the interior lines; it also encompasses exterior cleanliness and the practicalities of storage. Exterior cleaning should be gentle and deliberate. A soft cloth dampened with water is sufficient to remove dust, road grime, and minor residues from the pipe exterior. Harsh chemicals, solvents, or abrasive scrubbing should be avoided, as these can abrade the PVC surface and accelerate wear. The exterior, being visible to technicians and customers alike, also communicates the overall hygiene level of the vehicle. Keeping it clean reinforces professional standards and reduces the chance of cross‑contamination from dirt that could be carried into a client’s site.

In some operations, the pipes may run through environments where sanitation is paramount. In those cases, periodic sanitization is prudent and sometimes required. When the truck serves food service, medical, or pharmaceutical applications, sanitize the system with sanitizers that are FDA‑compliant and approved for use on PVC. Always follow the manufacturer guidelines for contact time and thorough rinsing. This ensures that the cleaning process itself does not introduce new residues into the system. The emphasis here is not on a generic test but on aligning cleaning actions with the specific requirements of the job, so the piping is ready for the next service with no carryover of contaminants.

Storage between jobs is another critical dimension. If the vehicle will be idle for extended periods, drain the system completely and store it dry. A dry environment discourages mold, algae, and bacterial growth that thrive in damp, dark places. Proper storage reduces the risk that pests or dampness alter the piping or seals during downtime. When the truck returns to service, the team can re‑establish normal operations quickly, knowing the pipes are dry and in good condition. This practice is not merely about avoiding a problem; it is about creating dependable readiness that keeps the service schedule intact and customers satisfied.

To translate these principles into action, teams benefit from a shared language and a clear set of responsibilities. The driver plays a central role in the hygiene and basic maintenance of the vehicle piping, but technicians and shop staff contribute critical oversight for deeper cleaning, inspection, and preventive actions. A collaborative approach ensures that every step from rinsing after a job to quarterly inspections is completed consistently. Documentation, checklists, and simple logs help track when maintenance occurred and what was observed. Over time, this data supports trend analysis, making it easier to predict when components may need replacement and to plan proactive interventions before issues escalate.

For leaders aiming to align maintenance with fleet realities, it helps to look beyond the immediate truck and consider industry perspectives on mobile fleet upkeep. For broader perspectives on maintenance across moving fleets, see the maintenance trends in trucking maintenance. In practice, that reference can serve as a guide to tailor a preventive program to the specific rhythms of your fleet—whether you run a single service truck or a small, private fleet with multiple units. The key is to keep the PVC piping clean and the system in balance with the rest of the truck’s operations, so every job starts from a clean slate and ends with a reliable, sealed network ready for the next call.

From an operational standpoint, the choice of cleaning cycles and inspection intervals should reflect the realities of your busiest seasons and the most demanding job profiles. When a truck covers long routes or works in challenging environments, the potential for residue buildup and minor abrasions increases. In those cases, a slightly more frequent inspection cadence may be warranted, paired with a proactive approach to replacing aging rings and seals before leaks appear. Conversely, a smaller fleet serving relatively uniform jobs can maintain a leaner schedule without sacrificing safety or sanitation. The overarching aim is a sustainable balance between thorough preventive maintenance and the practical limits of time and resources. Keeping PVC pipes clean on a service truck is about building a culture where cleanliness, reliability, and safety are not afterthoughts but core operating principles, woven into every job from intake to dispatch to post‑service follow‑up.

To connect with peers who manage maintenance across moving fleets, consider reviewing the internal perspective on private fleets trends in trucking maintenance. It offers real‑world insight into how other operators structure maintenance responsibilities, prioritize inspections, and foster a culture of cleanliness on the road. This aligns well with the practical steps outlined here and can help refine the program to fit the specific constraints and rhythms of your operation. Finally, for readers seeking a broader, externally validated framework, the following resource provides detailed guidance on PVC pipe inspection and maintenance best practices that can complement the on‑truck procedures described above: https://www.plumbingengineer.com/articles/2025-pvc-pipe-inspection-and-maintenance-best-practices

Final thoughts

Maintaining clean PVC pipes on service trucks is not merely a task but a vital practice that safeguards health and operational efficiency. By implementing regular rinsing, utilizing appropriate mild cleaning solutions, and conducting thorough inspections, businesses in manufacturing, retail, construction, and shipping can extend the lifespan of their plumbing systems. Effective maintenance practices not only prevent contamination and clogs but also ensure compliance and uphold the integrity of service trucks. As you adopt these strategies, remember that consistent attention to cleanliness translates into enhanced reliability and customer confidence.