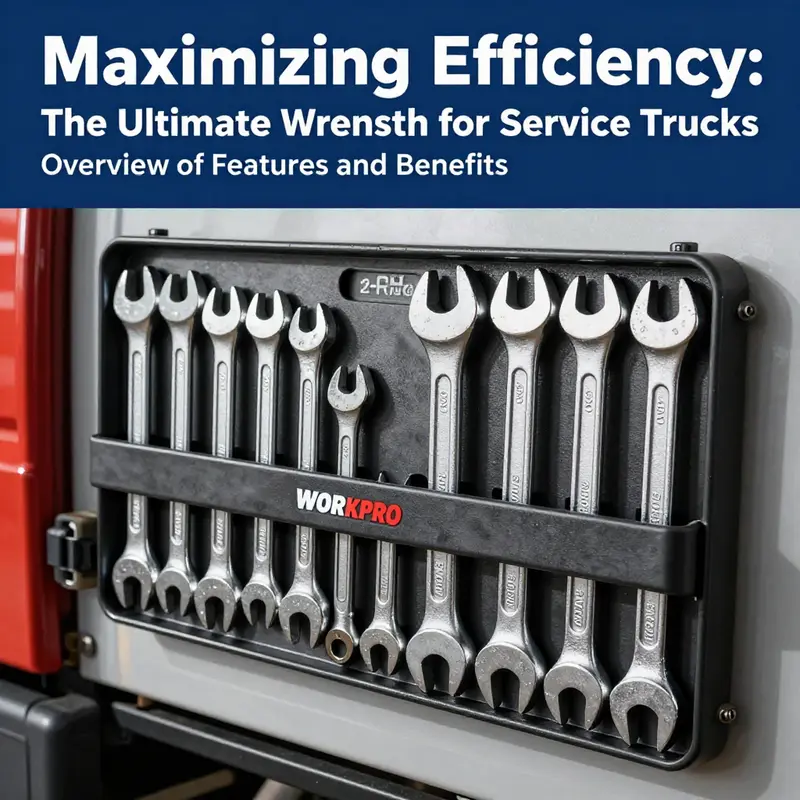

Selecting the proper wrench holder for a service truck is imperative for ensuring efficiency, organization, and speed in repair tasks. This choice directly impacts operational effectiveness, particularly for Manufacturing & Distribution Companies, Retail & E-Commerce Businesses, Construction & Heavy Industry Firms, and Small Business Owners with Shipping Needs. Throughout this exploration, we will detail the key features and benefits of top options, including a comparative analysis of the WORKPRO 2-Piece Magnetic Wrench Organizer against alternatives, delve into why effective tool organization is crucial, and showcase real-world applications of these tools in action. By the end of this article, readers will have a clear understanding of what constitutes the best wrench holder for their service truck requirements.

Moving Parts, Steady Wrenches: Why a Magnetic 24-Slot Organizer Is Ideal for a Service Truck

Every service call is a test of tempo and precision. A roadside repair, a municipal outage, a facility maintenance issue, or a fleet diagnostic in the middle of a sprawling site—each scenario demands not just the right wrench, but the right arrangement. For crews who rely on a service truck as a moving workshop, the way tools are stored can determine how quickly a problem is diagnosed, how safely it’s resolved, and how reliably the vehicle remains in service for the next assignment. In this context, a magnetic wrench organizer with a 24-slot capacity represents more than a storage accessory. It embodies a strategic shift in field operations, turning a jumble of wrenches into an orderly, instantly accessible toolkit that travels with the truck as efficiently as a built-in lighting system or a hydraulic lift. The core idea is straightforward: when wrenches of every size are secured in a predictable pattern, technicians spend less time searching and more time repairing, which translates into reduced downtime, improved safety, and greater velocity in meeting maintenance commitments across departments and terrains.

The essence of the best wrench holder for a service truck lies in three interlocking capabilities: organization, durability, and accessibility. Organization matters because field service work rarely happens in a clean, controlled environment. The truck bed may be dusty, the cab may shift with the road, and the job site can be cramped or elevated. A 24-slot design that accommodates both SAE and metric sizes delivers comprehensive coverage. On one panel you can house the imperial range from 5/16 to 3/4 inch, and on the same system you can fit the metric spectrum from 9 mm to 20 mm. This dual compatibility is essential in fleets that operate across regions or with diverse equipment, from emergency response rigs to utility trucks and municipal maintenance units. When a mechanic can locate the exact template of a size without hesitation, there is no scrambling for the right tool, only smooth, decisive action.

Magnetism, in particular, plays a pivotal role in service-truck dynamics. A magnetic backing ensures the wrenches stay in place while the vehicle continues to traverse rough roads, sudden stops, or detours around a construction zone. The benefit is twofold. First, it prevents tools from sliding and falling, a recurring hazard that can injure a technician or damage other gear. Second, it enables quick, one-handed access. In the moment a wrench is needed, the operator might be holding a connector, supporting a client, or balancing a step-ladder. A strong magnetic strip lets a wrench be picked up, removed, and replaced with a single motion. This fast cycle—from retrieval to operation to return—keeps the workflow flowing and reduces micro-delays that accumulate across back-to-back service calls.

Durability completes the trio. Field environments—whether hot rural roads, cold urban corridors, or damp industrial sites—test every component of a truck’s outfitting. The best magnetic organizer is constructed from premium materials that resist wear, corrosion, and the everyday abuse of high-mileage service work. The panel needs to withstand repeated insertions and withdrawals, resisting bending, cracking, or premature wear that would loosen wrenches or degrade magnetic strength. A robust finish protects against rust and grime, while a design that tolerates dusty or oily conditions without losing grip or alignment matters as much as the exact number of slots. The goal is not a fragile, once-off solution but a dependable system that holds up across seasons, across routes, across nights when work must be conducted under weak field lighting or at aerial heights where every tool must be in reach.

The pragmatic value of a 24-slot, dual-range organizer extends beyond the mere act of stowage. When a service truck is outfitted with lighting for night operations, access panels for the work area, and perhaps an aerial lift or telescopic boom for elevated tasks, everything that supports operational readiness reinforces the core function of the wrench holder. The organizer becomes a node in a larger network of tools and equipment, coordinating with lighting, access equipment, and the truck’s storage architecture. In these coordinated systems, the wrench holder isn’t a standalone gadget; it is part of a carefully calibrated workflow that accelerates response times and stabilizes the job sequence. In the field, a well-thought-out tool organization strategy reduces cognitive load. Technicians don’t have to memorize where each size is stored, nor do they have to rummage through trays or drawers to locate the correct wrench. Everything is deliberate and predictable, a comfort that translates into fewer errors when a job demands precision under pressure.

A key consideration in adopting such an organizer is the breadth of sizes it can accommodate. The fact that it can hold both imperial and metric wrenches is not merely convenient; it is a practical requirement for modern fleets. Equipment, infrastructure, and vehicles from different manufacturers use a mix of standards. When a technician arrives at a location with a metric-heavy repair, the transformer is immediate: the 9 mm through 20 mm range is ready, and the same system can still accommodate the SAE sizes that might be in use on another piece of equipment on site. The uniform layout reduces the chance of mixing up sizes, a mistake that can lead to stripped bolts or delayed service. In effect, the 24-slot arrangement becomes a portable library of wrenches, organized by size in a way that aligns with how technicians think about their work: by the scale of the fasteners they encounter most frequently.

Beyond the technical attributes, the organizational philosophy behind a magnetic wrench holder mirrors how fleets are increasingly rethinking their maintenance strategies. Modern service operations favor modular, upgradeable tools and components. A magnetic organizer is simpler to replace or relocate if there is a need to reconfigure the truck’s interior for a particular contract or a new service line. If the fleet adds a night-operations package, or if a new role requires more access for overhead repairs, the organizer can be relocated or expanded with minimal disruption. This adaptability resonates with the broader trend in trucking maintenance where agility, rather than rigidity, is prized. In this sense, the tool holder is not just a product but a strategic asset that supports adaptive service delivery and faster incident resolution across a fleet’s footprint. And because efficiency cascades through the operation, every second saved in tool retrieval becomes a tangible return on investment when multiplied across dozens of daily service calls.

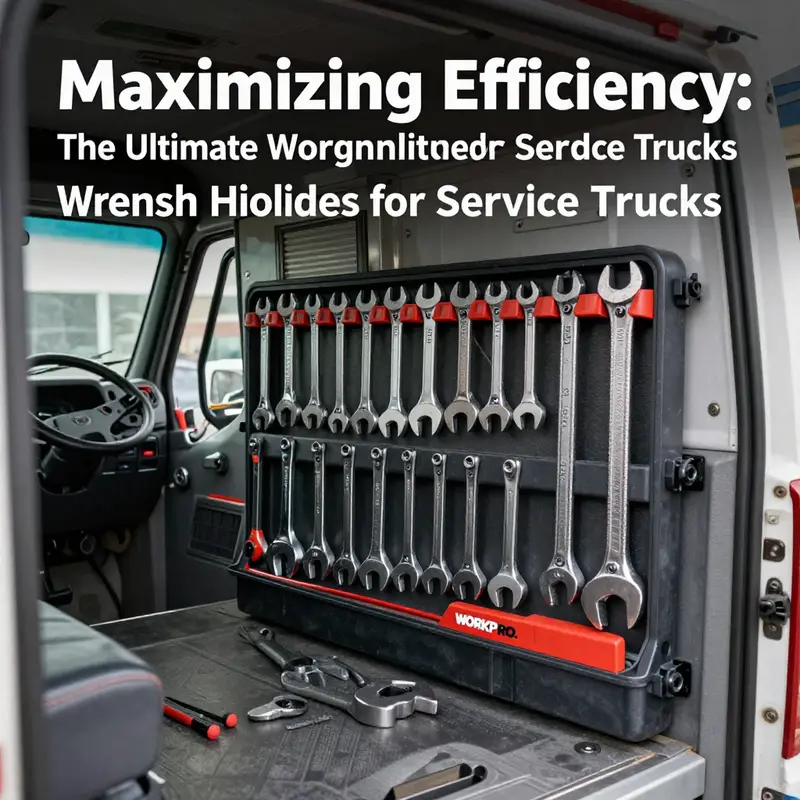

The decision to invest in a magnetic, 24-slot solution should be framed within the broader logistics of fleet outfitting. A service truck’s body is often a complex ecosystem: a robust chassis, weatherproof compartments, lighting rigs, and sometimes auxiliary power sources. The wrench organizer integrates into this ecosystem by occupying a compact, ferrous-friendly space on a panel or interior surface where it can anchor to the truck’s metal structure. The placement should be deliberate—near the workshop area, close to the power supply, and at a height that minimizes the need to bend or reach in awkward positions. It should also be positioned so that technicians can maintain a natural workflow: retrieve the needed wrench, apply torque, and return it to its slot without interrupting the sequence of the job. A balanced layout that respects the technician’s approach to problem-solving is essential for sustaining throughput on long shifts or during heavy maintenance campaigns.

To place this in the context of fleet strategy, consider the way a truck body is configured to support efficient night work or high-visibility tasks. A well-coordinated set of tools works in harmony with area lighting and the electrical system, enabling crews to perform precise work in challenging conditions. A magnetic wrench organizer supports such coordination because it limits tool travel and simplifies the workflow. In night scenarios or in tight spaces, the magnet’s hold helps keep sensitive wrenches from rolling or slipping, ensuring that the correct wrench remains immediately accessible when a bolt suddenly resists turning. The result is a more confident and steady operation, with fewer interruptions caused by mislocated tools or mis sized fasteners. Over time, that consistency builds into a culture of reliability, a key differentiator for service teams that aim to deliver predictable results on every assignment.

From a decision-making perspective, the choice of this type of organizer also aligns with practical budgeting considerations. While more complex tool carts or fixed wall racks have their place, a magnetic, 24-slot system offers exceptional value by delivering a high degree of organization and accessibility without imposing a heavy weight or significant installation complexity. It can be installed in minutes on an existing panel, or integrated into a compact tool cabinet with minimal modification. For teams constrained by budget yet seeking a meaningful uplift in productivity, such an organizer is a lean solution that yields outsized gains in daily operations. This appeal is especially strong for private fleets that must balance maintenance costs with uptime guarantees and service-level commitments, a balance that directly correlates with the fleet’s ability to meet customer needs on time and within budget. In this broader landscape, the tool holder becomes a practical, scalable upgrade that complements other investments in lighting, accessibility, and hydraulic or mechanical aids.

For readers exploring how tool management intersects with your fleet’s maintenance strategy, consider the longer-term implications. The trend toward smarter tool management, supported by durable, easily accessible organizers, reflects an overarching push to reduce downtime and improve reliability across the service chain. This is not merely about tidying up a few wrenches; it is about building a resilient operating model where every element of the service vehicle—from the storage system to the lighting to the lifting equipment—works in concert. The 24-slot magnetic organizer embodies that philosophy by bringing clarity to tool allocation, reducing the cognitive load on technicians, and enabling faster, more precise repairs under the varied conditions that characterize road and field work. It is, in essence, a microcosm of a larger systems approach to maintenance, where careful design improves performance at the smallest scale and, by extension, strengthens the entire workflow.

In the spirit of continuous improvement, it is useful to view the wrench holder as a modular component within a broader suite of outfitting decisions. When combined with a robust, customizable truck body that supports integrated work lights and area lighting for night operations, as well as compatibility with aerial lifts or telescopic booms, the gains in productivity and safety can be substantial. Such synergies are especially meaningful for municipal crews, utility districts, and industrial facilities that rely on rapid response and consistent uptime. While the initial investment may be higher for a more advanced setup, operators often recoup the cost through faster repair rates, reduced tool loss, and improved worker safety. Finally, the best wrench holder is not just measured by the number of slots it offers or the strength of its magnet. It is evaluated by how seamlessly it integrates into the technician’s daily rhythm, how it supports safer and quicker repairs, and how it reinforces the fleet’s commitment to dependable service on every job.

For companies and technicians seeking to situate this choice within a wider industry narrative, one can see a growing body of evidence that supports smarter tool management as a core driver of efficiency in trucking and maintenance operations. This perspective aligns with broader industry shifts toward more efficient fleets, better maintenance practices, and sustainable approaches to service delivery. As fleets update their maintenance playbooks to address increasing demand, supply chain pressures, and evolving regulatory landscapes, the emphasis on reliable, accessible tools becomes a concrete, actionable priority. The magnetic, 24-slot organizer offers a compact, practical solution that can be deployed across varied trucking environments, delivering tangible improvements in uptime, safety, and productivity. In other words, it is a tool with strategic value, not merely a tool to store tools.

Internal linking note: within the broader context of fleet efficiency and maintenance trends, many operations are reassessing their tool management strategies to improve response times and reliability on the road. For a deeper look at how private fleets are adapting to these maintenance realities, see the discussion on private fleets trends in trucking maintenance.

External resource: for practitioners seeking a real-world listing that demonstrates the design concepts discussed here, the following external reference provides a practical example of a 24-slot magnetic wrench organizer and its utility in field service settings: https://www.amazon.com/dp/B0CZQJFVYK

Secure in Motion: Elevating Service-Truck Tool Readiness with a Magnetic Wrench Organizer

A service truck is a small, autonomous workshop on wheels, a moving command center where repairs must be ready, fast, and precise. The terrain shifts under the chassis, streets rattle with the irregular rhythm of a workday, and the load of mechanical tasks compounds the risk of dropped tools or misplaced wrenches. In this setting, the way tools are stored is not a trivial detail but a cornerstone of operational efficiency. A system that keeps wrenches secure while still allowing quick one-handed access can shave minutes off each repair, prevent tool loss in transit, and reduce the clutter that often steals focus from the job at hand. Rather than relying on bulky boxes that slide and rattle during transport, technicians increasingly favor compact, purpose-built organizers that leverage magnetic retention and precise slotting. Such a design addresses two persistent pains: the challenge of keeping multiple sizes readily available and the fear of tools tumbling from a tray during a roadside pivot or a sudden stop. When a wrench is where you expect it to be, the task begins with confidence rather than rummaging through a jumble of metal and shadows.

A well-conceived magnetic wrench organizer does more than hold tools in place. It creates an immediate visual map of what is present and what is missing, a quiet assurance that the right size is within arm’s reach as the job unfolds. In mobile maintenance work, every second saved compounds into a broader return on investment. A standard, 24-slot design, capable of housing both SAE and metric wrenches, aligns with the most common repair scenarios technicians face across a broad spectrum of fleets. The sizes typically covered—ranging from smaller 5/16 inch up to 3/4 inch, and from 9 millimeters to 20 millimeters in metric—mirror the tools professionals most frequently reach for on site. This breadth of coverage minimizes the need to switch between multiple organizers or to rummage through a toolbox while the client’s machine sits idle in the drift of a busy service bay.

The magnetic retention at the heart of such organizers is not a luxury but a necessity in a moving vehicle. Chrome-plated, steel-based constructions with strong, evenly distributed magnets ensure that each wrench remains anchored even when the truck is traversing rough pavement or making a tight turn on a crowded job site. The risk of tools tipping or sliding out of an open tray is significantly reduced, which translates into fewer dropped wrenches, fewer lost tools, and less downtime spent hunting in the back of the vehicle. The confidence that comes from magnetic retention also changes how a technician approaches the workday. It enables one-handed retrieval while the other hand is still supporting a component, or allows for precise placement in a narrow workspace between a vehicle frame and a crowded engine bay. This is not merely about convenience; it is about creating a smoother workflow in environments where space is scarce and the work is time-sensitive.

Durability follows retention in the logic of a hard-working service truck. A premium construction that resists rust, wear, and the strains of field use is essential when tools are exposed to the elements, temperature swings, and the constant vibrations of a moving worksite. The materials chosen must balance stiffness with a respectful weight, ensuring the organizer remains stable yet easy to mount or reposition when the truck configuration changes. In practice, a robust organizer will resist bending or warping under the load of a full set of wrenches, maintain its slot integrity after repeated insertions and removals, and tolerate the occasional harsh impact that comes with urban deliverables and remote job sites. The last facet—ease of maintenance—matters too. A wipe-clean surface that resists grease and dust keeps the system looking professional and functioning reliably, reinforcing the technician’s sense of control as they navigate a day defined by unpredictability.

When selecting a wrench storage solution for a service fleet, the question is not simply which product can hold the most tools, but which design best aligns with the rhythm of mobile work. A 24-slot configuration provides substantial capacity without becoming unwieldy, and its compatibility with both metric and SAE wrenches speaks directly to the practical realities of most fleets. The ability to accommodate a mix of common sizes within a single, centralized rack means less back-and-forth searching and fewer separate trays to manage. For technicians who frequently encounter a blend of domestic and international equipment, this dual compatibility is a crucial feature, reducing the cognitive load of tool selection under pressure. In addition, the front-facing access that magnetic organizers offer supports quick, one-handed manipulation—a key advantage when the other hand is needed to stabilize a car, truck, or machine while making an adjustment.

The value proposition of a magnetic wrench organizer becomes even clearer when considered alongside ancillary storage components that often accompany mobile tool systems. A comprehensive approach to organization, one that pairs a wrench holder with a socket tray or other modular accessories, can yield a coherent workflow across the entire toolbox on wheels. By centralizing storage for the most frequently used wrenches and sockets, technicians can cultivate a streamlined, repeatable routine: locate the subset of tools needed for a given repair, perform the work, and return everything to its assigned slot with minimal disruption. This integrated approach supports a service team’s broader goals—quicker response times, higher first-visit completion rates, and a more predictable maintenance schedule for client fleets. In practice, the synergy between a magnetic wrench organizer and a matching socket storage component translates into a tangible reduction in time spent on logistics rather than on the repair itself, which is particularly meaningful during emergency repairs or urgent maintenance that cannot wait.

Beyond raw performance metrics, the true test of any tool-storage solution lies in installation practicality and adaptability to different truck configurations. Service fleets vary widely in their vehicle layouts, interior dimensions, and mounting options. A design that can be mounted on a cabinet door, integrated into a drawer system, or attached to a service tray without requiring invasive modifications offers a decisive advantage. The ideal magnet-and-slot system lands somewhere along a spectrum of ease: it should be straightforward to install with minimal hardware, durable enough to hold up under daily vibrations, and flexible enough to reposition when vehicle interiors are reconfigured for different shifts or task types. For operators who rotate between emergency callouts and scheduled maintenance, the ability to adapt on the fly matters as much as raw hold strength. The best solutions also consider cable management and the avoidance of interference with other tools or devices mounted nearby. A well-thought-out layout minimizes the chance of snagging or accidental dislodgement as technicians move around the cab and the engine bay.

The strategic advantage of magnetic organization extends into the culture of field service as well. When teams rely on consistent tool placement, supervisors gain a clearer picture of workflow and inventory health. Replenishment becomes more predictable because the slots offer a quick visual check of what is missing. This lowers the risk of tool loss during long hauls or at remote sites and contributes to more stable job costing. The reliability of a tool layout affects not only timekeeping and productivity but also safety. If wrenches are sliding around in a bin or sliding off a shelf, the risk of injury rises as technicians reach for one that might be in an unexpected place. A dedicated, magnetized rack that keeps tools in their designated slots reduces the chance of sudden tool movement and the potential for accidents during a dynamic workday.

To make the case more concrete for fleet managers who weigh the cost of upgrading tool storage, consider the broader industry context. Across private fleets and mobile maintenance operations, there is a growing emphasis on tool readiness as a core performance metric. Managers recognize that the time saved by eliminating tool searches accumulates over dozens or hundreds of service calls each month. The resulting uptime improvement translates into more completed jobs per day and higher customer satisfaction, both of which have meaningful implications for service levels and contract performance. In conversations about maintenance practices and tool strategy, this emphasis on readiness often surfaces alongside discussions about standardization, durability, and total cost of ownership. A magnetic wrench organizer, as part of a cohesive tool-storage ecosystem, is not a flashy gadget but a disciplined choice that aligns with lean, reliability-focused maintenance programs.

Industry realities aside, the practical choice of a specific system should be guided by the actual work profile of the fleet. If the typical job involves frequent stops in urban corridors, tight shop spaces, and rough roads, the compact, high-retention design offers the greatest value. If, instead, the fleet operates in more controlled environments where tools are moved between fixed workstations, a slightly larger or more modular approach might be appropriate. Either way, the central idea remains consistent: tools should be accessible when needed, protected during transit, and easy to put away after use. The right wrench organizer, paired with compatible storage components, helps maintain a clean, professional interior that reflects well on the service team and reinforces good maintenance habits.

For readers interested in broader context about how maintenance practices are evolving within the trucking and private fleet sectors, a recent overview of trends in private fleets highlights the continued push toward smarter, faster field work and more reliable on-site execution. This backdrop helps explain why a magnetic wrench organizer is not merely a convenience but a strategic instrument in a modern service operation. See the discussion of industry trends and maintenance priorities in this overview: Private Fleets Trends in Trucking Maintenance.

In sum, the best wrench storage solution for a service truck marries practical retention with thoughtful design, providing a compact, durable, and adaptable tool-holding system. A 24-slot, magnetized organizer that accommodates both SAE and metric wrenches rises to meet the exacting needs of on-the-go repairs, enabling technicians to work with speed, precision, and confidence. It supports a holistic approach to tool workflow, complementing socket storage and other modular components to deliver a seamless, integrated setup. It also aligns with the broader move toward standardized, efficient maintenance practices in mobile fleets, where uptime and reliability are the currency of success. The result is a more organized cab, a more predictable repair process, and a service operation that can respond quickly to the demands of clients and the realities of shifting road conditions.

External reference: For more technical detail on a magnetic wrench organizer set, see the official product page here: magnetic wrench organizer set.

On the Move and Ready: The Critical Role of Wrench Holders in Service Trucks

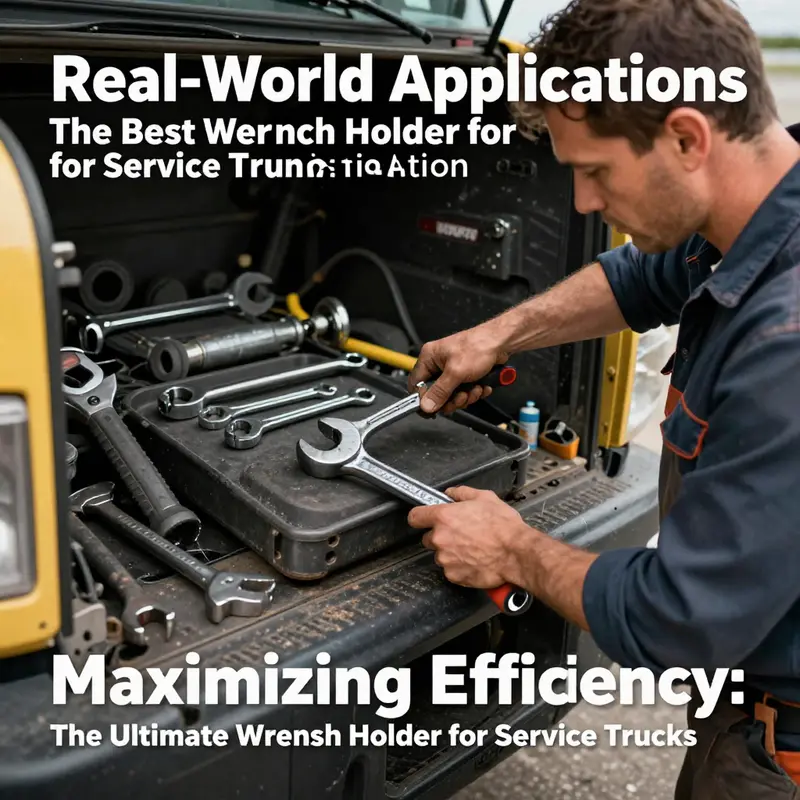

A service truck is a rolling workshop, a small factory on wheels where decisions are made at the speed of a wrench turn. The human mind demands clarity, and the body requires a workflow that keeps both hands free for the job at hand. In the field, momentum matters. A client is waiting, a tire must be changed, or a brake line needs a quick adjustment. In those moments, the difference between a smooth, successful repair and a frustrating scramble often comes down to tool organization. Wrenches, the most common and dependable of fasteners, are the backbone of on-site repairs. When they are not properly organized, the consequences ripple through the workday: wasted minutes spent searching, dropped tools rolling under the chassis, or mismatched sockets that force improvised, less precise torque. The wrench holder, in this context, is more than an accessory. It is a compact system designed to synchronize speed, accuracy, and safety across a shifting landscape of jobs and environments. When a technician opens the cabinet or reaches for a tool held fast by magnets, there is a small moment of confidence. The tool is where it should be, ready for action, and the mind can focus on the task rather than the apparatus of the task.

In heavy-duty maintenance settings—whether performing tire changes, brake work, or suspension adjustments—the immediacy of tool access translates directly into efficiency and safety. Wrench holders that are well conceived do more than store tools; they curate a sequence of actions. They ensure that the most frequently used wrenches are accessible with a single maneuver, that the range of sizes covers the needs of both SAE and metric systems, and that the tools stay put even as the vehicle barrels down a city street, hits a pothole, or makes a sharp turn. The essence of a good wrench holder is not merely capacity but strategic organization: a layout that mirrors the typical repair flow, a construction that resists the rigors of daily use, and a mounting option that fits cleanly into the interior or exterior of a service vehicle. When those criteria align, the wrench holder becomes a reliable partner, reducing cognitive load and preserving tangible assets under the harsh conditions of field service.

The most fundamental attribute of an effective wrench holder in a service truck is its capacity and layout. A robust organizer is designed to accommodate a broad spectrum of sizes, from small metric wrenches to larger SAE versions, with a total slot count that anticipates common repair tasks without forcing the user to rearrange tools mid-job. In the wild, a system with 24 slots is not a luxury; it is a practical balance between granularity and speed. Such a configuration supports a practical, almost ritual, arrangement of tools in a way that makes sense to seasoned technicians. The slots must be carefully shaped so that each wrench seats securely and slides out smoothly with minimal resistance. A well-balanced layout discourages misplacements and accidental mixing of sizes, which can be costly in high-tidelity tasks like adjusting caliper bolts or aligning suspension components where precision matters as much as speed.

Strength and resilience are non-negotiable in a service truck environment. The chassis is a high-vibration, high-motion workplace, and the organizer must withstand dust, moisture, and the inevitable bumps of road travel. Materials should resist corrosion and wear, with finishes that tolerate gas, oil, coolant residues, and the grime of daily field service. A magnetic retaining system, when thoughtfully engineered, adds a layer of practicality that is not optional but essential. The magnet should provide reliable grip for metallic tools without risking inadvertent detachment during acceleration, braking, or sudden maneuvers. The goal is a secure, one-handed retrieval that keeps the other tool in hand and the technician focused on the task, not on tool management. In practice, this translates to a magnetic surface that offers just enough pull to hold wrenches in place, yet releases cleanly when pressed or pulled for quick access. The right balance reduces the temptation to “double-grip” or cradle a tool awkwardly for fear of dropping it, a habit that can slow down a repair and create safety hazards around hot components or energized lines.

Beyond capacity and magnetism, the durability of the wrench holder is a reflection of the broader reliability ethos that underpins successful field service programs. A well-made organizer should resist deformation when tools are removed and replaced repeatedly, maintaining the alignment of slots so that the next wrench fits with the same ease as the last. This is especially critical in environments where technicians need to move rapidly from one job to another, often in cramped spaces where clearance is tight. A sturdy, well-secured mounting system is equally important. The ability to position the organizer for optimal reach—whether mounted on a vertical panel near the driver’s seat, tucked under a bench, or fixed along a cargo wall—translates directly into ergonomics and safety. The quick-release, lock-in design of the mounting hardware ensures that the wrench holder does not shift or rattle during transit, which would degrade tool organization over time and create a distracting, noisy workspace in the cab or back of the truck.

The practical implications of a properly chosen wrench holder extend into the realm of compliance and standardization. Field technicians operate within a framework of best practices and industry standards that prescribe orderly, auditable work environments to minimize errors, protect equipment, and ensure reproducible results. A neatly arranged set of wrenches makes it easier to verify that tool inventories are complete and in the expected condition, a factor that matters during inspections or audits of maintenance workflows. In addition, the arrangement of wrenches can reinforce proper torque procedures. When the correct size is easily identifiable, the likelihood of cross-threading, under-torquing, or over-torquing decreases. The mental model of the technician—one that trustingly relies on the visible, accessible repertoire of wrenches—supports consistency in repair quality. And consistency matters: it reduces variability in performance, which translates to longer service life for components and fewer call-backs on roadside repairs, both of which have clear economic and safety benefits.

An interesting dimension of tool organization arises when technicians consider the full ecosystem of their mobile workshop. A wrench holder does not exist in isolation; it sits within a network of tools and storage solutions designed to keep the truck moving. The ideal system offers compatibility with common mounting configurations and can be integrated with other storage modules to create a cohesive, modular workflow. For instance, a magnetic organizer can be paired with additional trays or slots that hold sockets, pliers, or screwdrivers in a way that preserves the responsive, one-handed workflow. The synergy between tools matters as much as the tool choices themselves. When a mechanic can reach for multiple tools in quick succession without breaking the rhythm of a repair, stress decreases, and task focus improves. This is not just about convenience; it is about enabling technicians to apply their expertise more consistently and safely under pressure.

The theoretical advantages of a well-designed wrench holder gel with real-world experiences in the field. In maintenance practices that require rapid response—like emergency brake adjustments or tire rotations in fleet operations—the ability to locate and extract the right wrench within a split second reduces downtime and elevates service quality. The impact is cumulative: fewer interruptions, more complete tasks in a single visit, and a smoother hand-off when a job is completed and the vehicle returns to service. For teams operating across geographical regions and varying shift patterns, standardized tool organization protocols, supported by a robust organizer, help preserve continuity. New technicians can learn the expected tool layout quickly, while veterans can rely on a proven system that minimizes the cognitive load of tool management amid a high-stakes task.

To connect these practical insights with broader industry perspectives, consider the maintenance rhythms of private fleets and how they inform tool selection and workflow design. The ongoing trends in trucking maintenance—shaped by evolving regulations, maintenance scheduling practices, and the need for rapid travel-ready repairs—underscore the value of a reliable, easily accessible wrench holder. A clear takeaway is that the right organization solution does not merely store tools; it enables a dependable, repeatable maintenance process. It supports speed without sacrificing accuracy and safety, which are the twin pillars of professional field service. In this light, the choice of a wrench holder becomes part of a broader strategy to optimize mobile maintenance, reduce downtime, and extend the life of both vehicles and their parts. For readers seeking a broader industry view on maintenance trends and fleet efficiency, an overview of private fleets trends in trucking maintenance can be informative private fleets trends in trucking maintenance.

While the specifics of a given organizer—such as 24 slots, compatibility with a defined range of wrenches, and the exact magnetic strength—will vary, the guiding principles remain constant. Prioritize a layout that mirrors the typical repair sequence, ensure robust materials and finishes that withstand solvents, dirt, and moisture, and choose a mounting scheme that fits the interior geometry of the vehicle without compromising access to other essential tools. The result is a wrench holder that is not merely a repository but a strategic component of the service envelope. In practice, technicians perceive the difference in real time: a tool that slides into a slot with a reassuring click, a handle that comes free with a simple lift, and a magnetic hold that keeps the set intact during rough road conditions. When those cues align, the entire operation benefits—from faster diagnosis to higher quality torque application and, ultimately, safer field work.

The broader takeaway is that tool organization matters as an aspect of professional discipline. It reflects a standard of care, a respect for the tools that enable work, and a commitment to delivering reliable service even under demanding circumstances. A wrench holder designed for mobile workstations should be unobtrusive yet transformative: it should disappear into the background as a facilitator of skilled labor, allowing technicians to focus on the job rather than the arrangement of their tools. When done well, organization becomes an invisible efficiency mechanism, an ordinary object that quietly supports extraordinary performance. For those seeking deeper technical grounding on tool standards and practical configurations, reference material on heavy truck workshop tools and their applications provides a rigorous foundation for decision makers and field technicians alike. External readers can explore a comprehensive resource on the technical standards, properties, and applications of workshop toolkits here: https://www.machineryhub.com/blog/heavy-truck-workshop-tools-kit-explained.

Securing Speed and Safety on the Move: A Field-Ready Wrench Organizer for Service Trucks

In the demanding world of mobile maintenance, a wrench holder is more than a simple accessory; it’s a critical component of the workflow. A service truck operates as a rolling workshop, and the difference between a smooth repair and a missed appointment often hinges on tool readiness. The best wrench organizer for this environment is a rugged, modular, magnetic system that can survive the jolts of road travel while delivering instant access to the tools technicians rely on. Picture a compact, 24-slot organizer crafted from reinforced materials, designed to hold a full spectrum of wrenches from SAE sizes to metric equivalents, and engineered to endure the heat, moisture, dust, and vibration of everyday field service. This isn’t about elegance for its own sake. It’s about resilience, speed, and reliability in situations where every second counts and misplacement can cause costly downtime. When a technician climbs into a service truck and faces a day of roadside repairs, fleet maintenance, and urgent diagnostics, the tool holder becomes a quiet, unsung partner that quietly contributes to safer, quicker, and more accurate work.

The appeal of a 24-slot, magnetic wrench organizer rests on the little things that compound into major efficiencies. First, the slot count covers a broad range of wrenches needed in field service. A practical setup includes both standard SAE sizes from 5/16 inch to 3/4 inch and metric wrenches from 9 mm to 20 mm. This breadth ensures that technicians are not forced to rummage through a mixed tool bag or switch between multiple containers when a bolt demands a specific torque or a quick nut swap. The integrity of the arrangement lies not only in the number of slots but in the clear, unambiguous layout. Each cavity is designed to hold a specific size with a mild, intentional grip—enough to keep the tool vertical during transit, yet easy to lift with one hand when the job demands it. It’s a simple balance, but one that saves seconds, and in fleet maintenance, seconds accumulate into minutes, then into saved hours over a month.

Durability is the second pillar. Field environments are unforgiving: construction sites vibrate, service trucks bounce on uneven roads, and a wrench that rattles loose or slides out can become a hazard or a lost tool. A robust organizer uses a steel or high-strength polymer frame, with a powder-coated finish or corrosion-resistant treatment to withstand humidity, road spray, and cleaning solvents. Magnetic retention should be strong enough to resist the occasional jostle yet forgiving enough to permit quick removal with a single, deliberate pull. Magnetic systems excel in service-truck use because they allow fast, one-handed access—crucial when a technician must hold a flashlight, pull a sensor, or manage a diagnostic device in tight spaces. More important than raw magnet strength is the overall enclosure design: a quiet, vibration-damped shell that holds each tool in its designated slot while keeping edges smooth to prevent nicks on tool handles or gloves.

The third merit is modularity. A field service operation rarely uses a one-size-fits-all approach. The ideal wrench organizer can be mounted inside the toolbox, affixed to a vertical wall panel, or slipped into a drawer and still retain its position when the vehicle travels over rough terrain. Modularity means that technicians can tailor the layout to the fleet’s common jobs—torque-critical repairs, brake service, or general maintenance—and swap modules as needs change. This capability is particularly valuable for fleets that service a mix of heavy-duty and lighter vehicles. In a typical day, one technician might handle a cross-section of tasks, from adjusting lug nuts to pulling a hex socket set for a brake rotor replacement. A well-designed organizer keeps torque wrenches, lug wrenches, and socket sets in a consistent, labeled arrangement. The result is a straightforward, almost ritual workflow: grab the wrench from its slot, apply torque to a specification, and return it to the exact same slot. Consistency reduces the cognitive load on the technician, letting them focus on the task rather than tool hunting.

To translate this into real-world efficiency, consider the daily rhythms of fleets that must minimize downtime and maximize uptime. In urban service routes, where the clock ticks loudly at a roadside stop or a depot-based repair, the ability to quickly switch between wrench sizes is not a luxury—it’s a necessity. A cross-shaped lug wrench with dual socket sizes, for example, is a common field tool for heavy-duty work. The capacity to rapidly select the appropriate size without rummaging through a disparate kit means faster tire changes, quicker alignment checks, and shorter shop-to-road transition times. In long-haul operations, the stakes are even higher. A driver-repair scenario may require precise torquing values or exact socket fits to maintain wheel integrity across miles of highway. The wrench organizer, by keeping tools in plain sight and immediately retrievable, reduces the risk of cross-threaded bolts or under-torqued assemblies. Such outcomes are not merely convenient; they affect safety, fuel efficiency, and regulatory compliance.

Beyond mechanical efficiency, a good wrench holder contributes to operational safety. Loose tools rolling around the cabin or banging against metal panels are a recurring source of accidents in moving vehicles. A magnetic organizer with secure slots minimizes this danger by holding tools firmly in place. It also protects tool edges from damage and reduces wear on the interior of the toolbox or paneling. The software-like precision of the layout matters here, too. Labeled compartments can be as simple as engraved or embossed indicators showing the size range for each cavity, creating a tactile and visual guide that speeds selection even when lighting is scarce or the technician is wearing gloves. In field conditions, where safety protocols vary by region, having a clearly organized, legible tool layout is a small but meaningful step toward consistent, safe practice. For teams that operate under hazardous material handling or other regulatory frameworks, the organization system becomes part of the documented safety plan, making inspections simpler and more thorough.

The real-world value of a field-ready wrench organizer is also measured in its impact on downtime. When a fleet is struck with an unexpected outage due to tool loss or misplacement, the ripple effects can cascade through dispatch schedules, customer commitments, and maintenance windows. An integrated organizer reduces the likelihood of such interruptions by providing a known, repeatable tool map. Technicians can train new hires more quickly because the tool layout is standardized across trucks, reducing onboarding time and the cognitive burden of learning different kits for different vehicles. In this sense, the organizer becomes not just a holder of wrenches but a facilitator of reliable service delivery. It supports the discipline of maintenance—an approach that treats tool management as a core part of fleet reliability rather than a peripheral convenience.

As fleets explore different configurations for interior storage, the selection criteria spread beyond the slots and magnets. The materials matter, too. Cleanability is essential in harsh environments, where oil, grease, and road grime accumulate on tools and trays. A resilient finish on the organizer resists staining and makes routine cleaning faster. The geometry of the slots matters as well. Slightly tapered or recessed cavities help prevent tools from tipping when exposed to lateral movement during travel. The overall footprint should balance capacity with the ability to fit along wall panels or within a toolbox without crowding. A curved or chamfered edge reduces the risk of glove snags and makes handling more comfortable after a long shift. These qualitative traits—cleanability, fit, and ergonomic grip—complement the core requirements of capacity and magnetism, rounding out a system that supports the full spectrum of field service realities.

To connect these design principles with the realities of industry practice, consider the integration of tool storage into the service truck’s workflow. The organizer can be mounted on an interior wall, adjacent to the toolbox, or even on the underside of a lid for quick thumb-access during a roadside repair. When mounted correctly, the module remains close to the heart of the operation, enabling a technician to pivot between diagnostic devices, torque settings, and wheel services without stepping away from the vehicle or relinquishing control of the workspace. The magnetic feature carries additional benefits: it prevents tool loss during sudden stops or tailgating winds, and it preserves the integrity of tool handles that are often the primary contact points for technicians. In this way, the organizer contributes to a safer, more efficient, and more professional service experience that benefits the entire fleet—and, by extension, the end customers who depend on prompt, reliable maintenance.

In discussions about field readiness, writers and practitioners frequently reference industry case studies and maintenance guides that anchor these ideas in tangible procedures. For instance, the broader conversation about wheel and tire service emphasizes how specialized tools, organized in a predictable layout, reduce process variation and improve torque accuracy. The cross-validated insights from these sources reinforce the principle that a robust tool organizer is not a mere accessory but an operational backbone. In regions with complex regulatory landscapes and stringent safety expectations, a well-organized set of wrenches also helps demonstrate due diligence during inspections and audits. The toolkit’s consistency becomes a quiet but powerful signal of professionalism, reliability, and a commitment to keeping fleets on the road.

Ultimately, the choice of wrench organizer should reflect the priorities of a given fleet: speed, security, durability, and adaptability. The ideal system aligns with the operational tempo of the service truck, adapts to the wide range of tasks technicians perform, and endures the rough realities of road travel. It becomes a core element of the vehicle’s interior architecture, shaping how tools move from the bench to the curbside, from diagnosis to repair, and back again. In this sense, the best wrench holder for a service truck is a design that embraces the friction between speed and precision, between transport and touch, and between the unpredictable demands of the field and the steady discipline of professional maintenance. For teams exploring the literature and case studies of fleet maintenance, a practical takeaway is the value of a modular, magnetic, 24-slot organization that foregrounds accessibility and protection. It is a tool system built not only to hold wrenches but to sustain uptime, safety, and service quality across a broad spectrum of real-world jobs.

For readers seeking broader context on how tool choices affect performance in rugged, day-to-day operations, see industry analyses such as Private Fleets Trends in Trucking Maintenance, which discuss how organized tool storage supports faster repairs and more reliable service delivery. This chapter’s emphasis on a magnetic, 24-slot approach is in line with those findings, translating high-level insights into a practical, field-ready solution. Private Fleets Trends in Trucking Maintenance.

As a closing thought, the external reference below offers deeper technical perspectives on tool performance under demanding conditions, complementing the practical, field-tested narrative presented here. External resource: https://www.machinist.com/truck-tyre-nut-wrench-guide/.

Final thoughts

In conclusion, the choice of wrench holder is not just about organization; it is about enhancing efficiency, ensuring quick access to tools, and bolstering the success of service operations in various industries. The WORKPRO 2-Piece Magnetic Wrench Organizer undoubtedly stands out for its seamless integration of functionality and durability. By selecting the right wrench holder, businesses can maximize productivity, reduce downtime, and ensure that essential tools are always on hand when it matters most. The insights shared here empower companies to make informed decisions that align with their operational needs.